Oil dry point prediction calculation method and device, computer equipment and storage medium

A calculation method and computer program technology, applied in the field of oil refining, can solve problems such as large gaps, large differences in the properties of isomers, and inaccurate calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

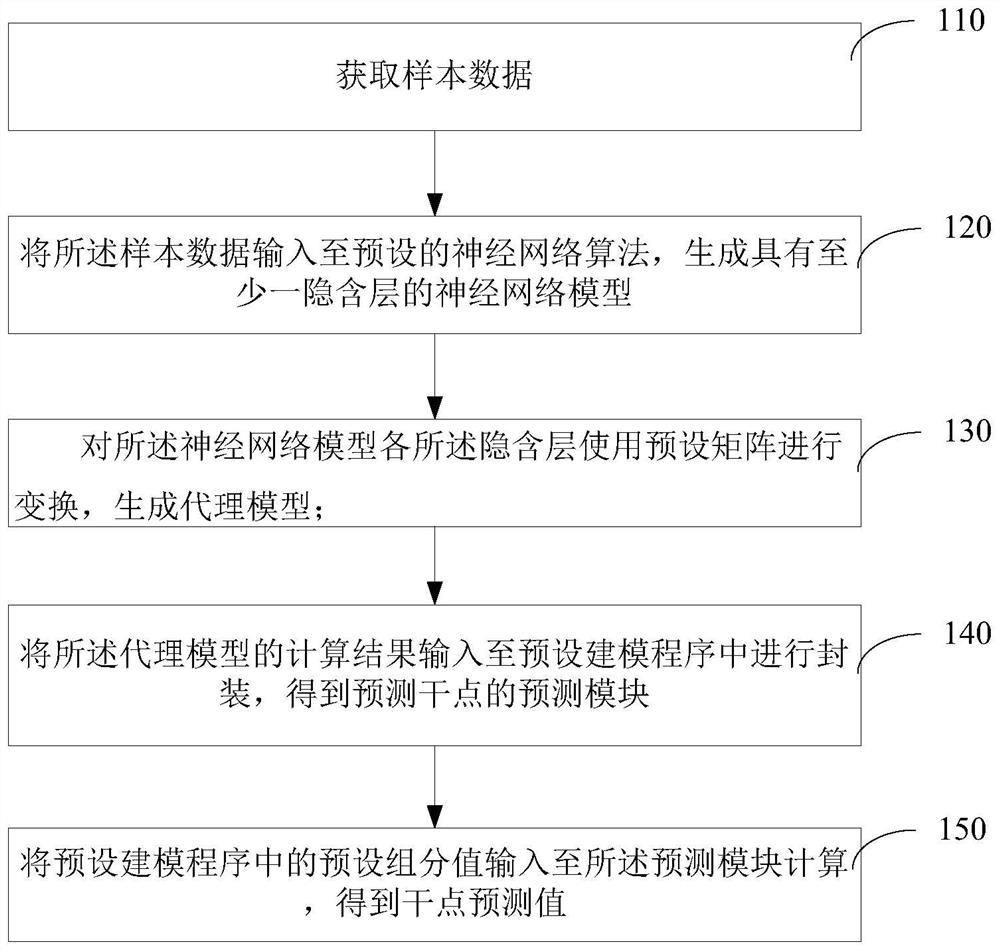

[0055] In this example, if figure 1 As shown, a method for predicting and calculating oil dry point is provided, which includes:

[0056] Step 110, acquire sample data.

[0057] In this embodiment, the amount of sample data is LIMS data, which is used as a sample of the neural network model. In this embodiment, the LIMS data is firstly screened to select appropriate data, and then the screened data is sorted to obtain sample data.

[0058] Step 120, input the sample data into a preset neural network algorithm to generate a neural network model with at least one hidden layer.

[0059] In this step, a neural network algorithm is applied according to the samples to generate a neural network model. In this embodiment, the sample data is the composition of oil and gas, the input of the neural network model is the composition, and the output is the dry point temperature. The specific calculation process of the neural network model is to input the measured values of all the cor...

Embodiment 2

[0081] It should be understood that online optimization is the most advanced optimization technology developed to the present stage of the whole process optimization control technology. It applies optimization technology to process control, and seeks to achieve the objective function to achieve the optimum value under the condition of meeting various production technical indicators. An optimal set of operating parameters is obtained, and this set of parameters is used for the actual control of the device.

[0082] Online optimization technology can make the production process in the best running state by only adjusting the operating parameters without modifying the process flow or adding production equipment. Online optimization technology can set the maximum benefit, high value-added yield, etc. as the objective function, without modifying the process flow, without increasing or reducing production equipment, only by adjusting parameters such as pressure, temperature, load, et...

Embodiment 3

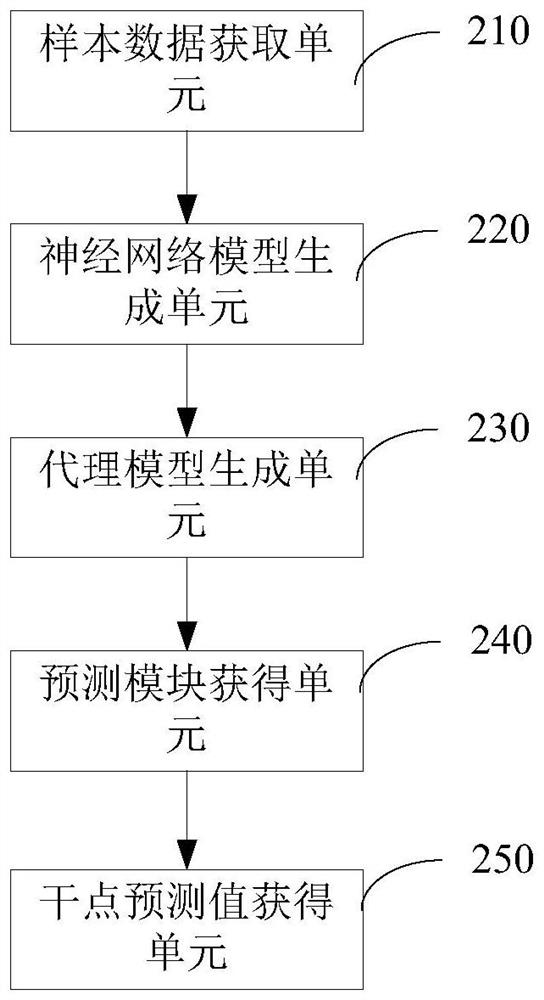

[0110] In this example, if figure 2 As shown, an oil dry point prediction calculation device is provided, including:

[0111] A sample data acquisition unit, configured to acquire sample data;

[0112]A neural network model generation unit, configured to input the sample data into a preset neural network algorithm to generate a neural network model with at least one hidden layer;

[0113] A proxy model generating unit, configured to transform each hidden layer of the neural network model using a preset matrix to generate a proxy model;

[0114] A prediction module obtaining unit, configured to input the calculation results of the proxy model into a preset modeling program for encapsulation, and obtain a prediction module for predicting dry points;

[0115] The dry point predicted value obtaining unit is configured to input the preset component values in the preset modeling program into the prediction module for calculation to obtain the dry point predicted value.

[0116...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com