Leather material surface defect detection method based on feature modeling significance detection

A defect detection, remarkable technology, applied in the direction of character and pattern recognition, image data processing, instruments, etc., can solve the problems of ineffective detection and positioning, and achieve the effect of convenient real-time processing, fast detection speed and shortened detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

[0046] The invention provides a leather material surface defect detection method based on feature modeling saliency detection, comprising steps:

[0047] S01, first collect the video information of the leather material, and select several frames of images in the video as images to be detected;

[0048] In a specific embodiment, a frame image is acquired every 1 second in the collected video as the image to be detected;

[0049] S02, then adopting a bottom-up model to perform preliminary acquisition of a saliency image to obtain a first saliency image;

[0050] The process of obtaining the first saliency image includes steps:

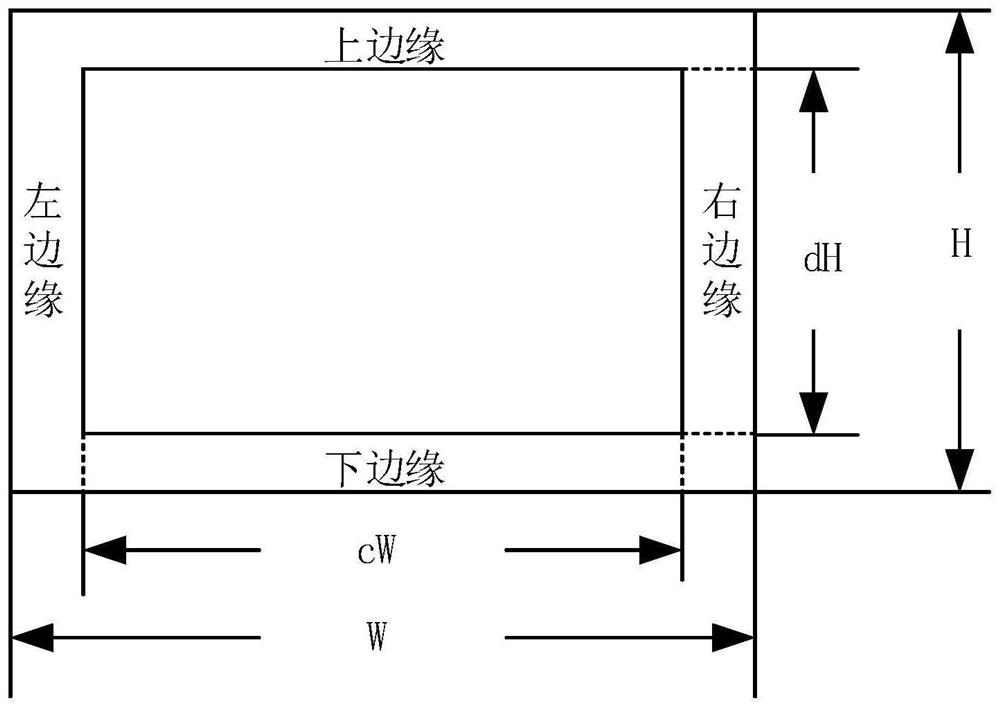

[0051] S021. First divide the image to be detected into a central area and an edge area, the central area is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com