In-service bridge bearing capacity evaluation method without resistance information

A bearing capacity, bridge technology, applied in the direction of instrumentation, geometric CAD, design optimization/simulation, etc., can solve the problems of no effective method for bridge evaluation, lack of design and construction materials, etc., to achieve strong practicability, high calculation accuracy, and high promotion value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] A method for evaluating the bearing capacity of in-service bridges without resistance information, the specific steps include:

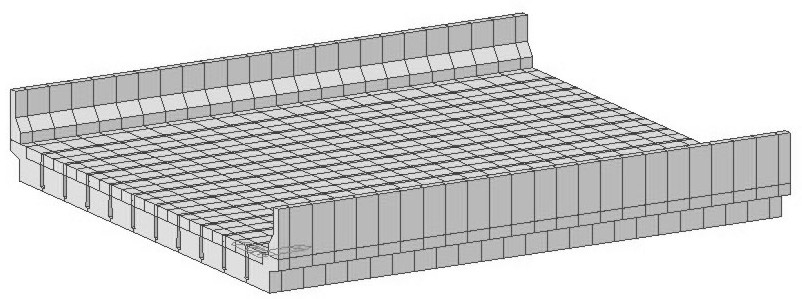

[0056] S1. In order to correctly calculate the dead load effect and establish a structural finite element model consistent with the actual situation, it is necessary to measure the geometric parameters of the bridge and investigate the dead load condition. Specifically, it includes bridge deck alignment, arch ring alignment, main cable alignment measurement, bridge overall size, component size, bridge deck pavement and arch filler thickness measurement, bridge additional load investigation, arch filler weight measurement, etc.

[0057] S2. Carry out a detailed visual inspection of the whole bridge, including the superstructure, substructure and bridge deck system, focus on inspection of the main load-bearing components, grasp the structural deterioration and damage, and analyze the impact of the disease on the bearing capacity; investigate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com