Semi-finished product power-on detection device for LED production

A testing device and semi-finished product technology, which is applied in the direction of measuring device housing, single semiconductor device testing, lamp testing, etc., can solve the problems of production line shutdown and low efficiency, and achieve the effect of high production efficiency and efficient automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

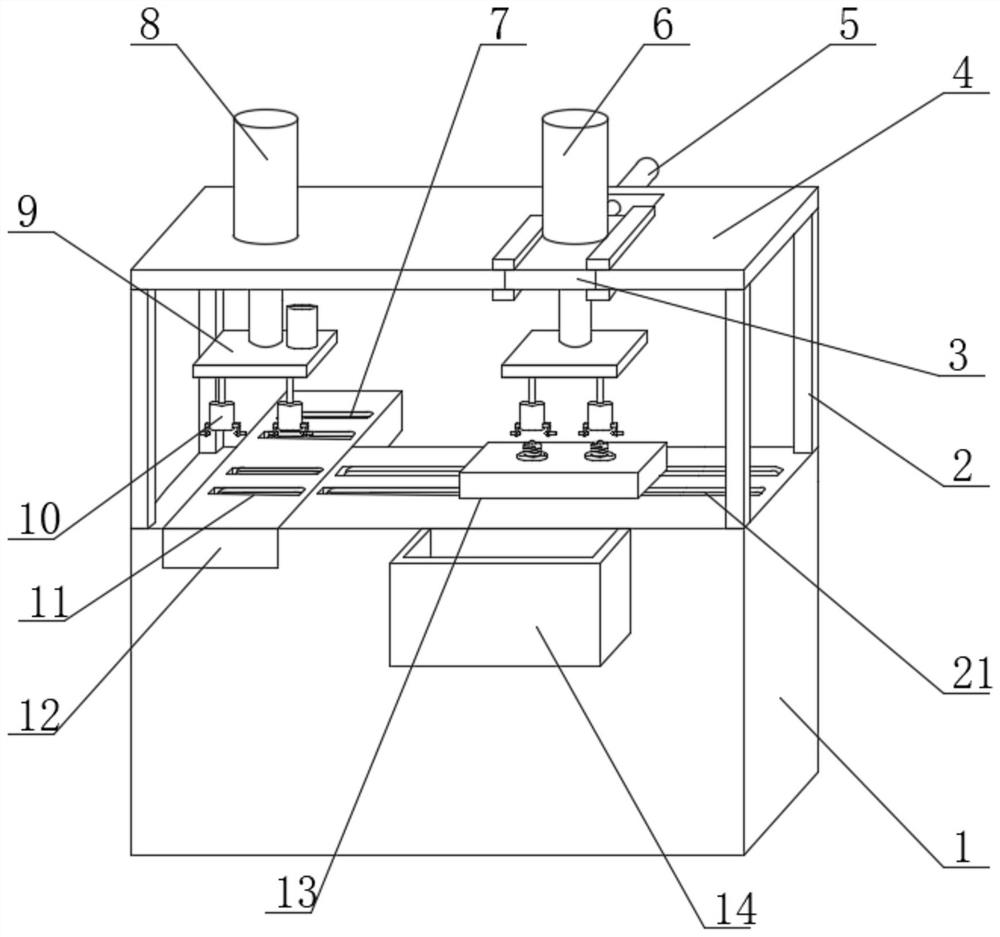

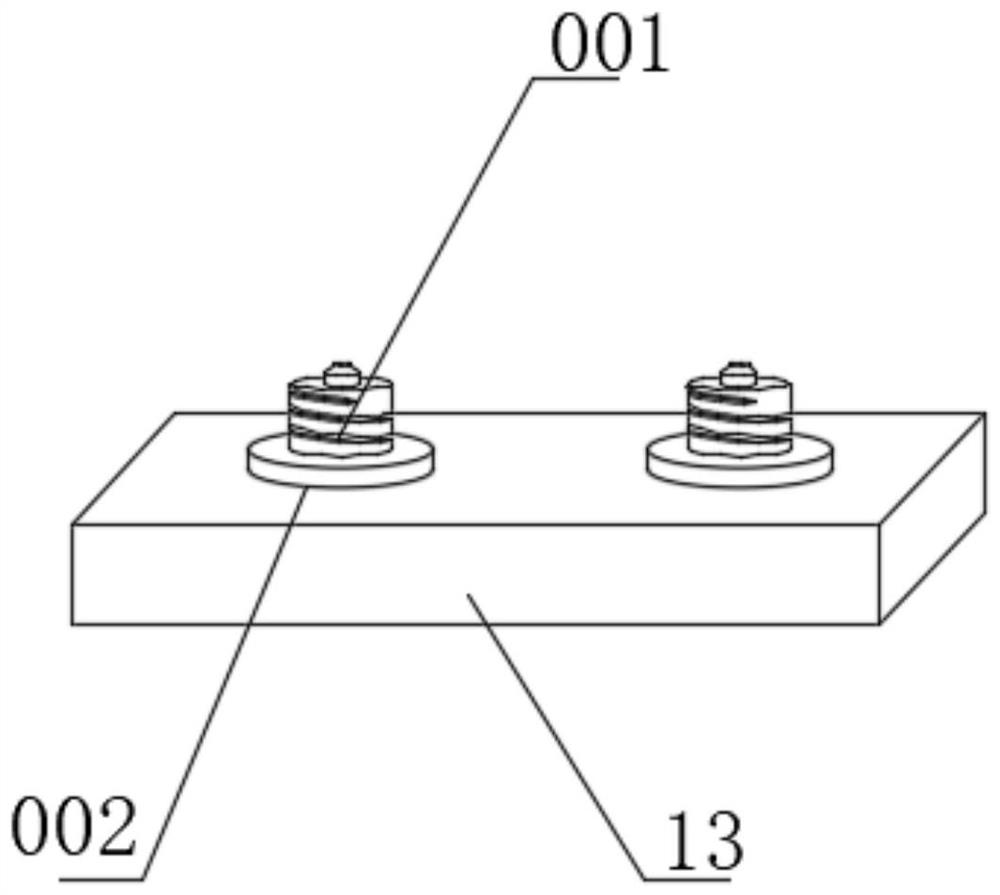

[0038] Examples, see figure 2 combine image 3 , the third conveyor belt 21 is installed on the top of the base 1, the top of the third conveyor belt 21 is placed with a clamp 13, the top of the clamp 13 is provided with two limit holes, and semi-finished lamps are placed in the limit holes;

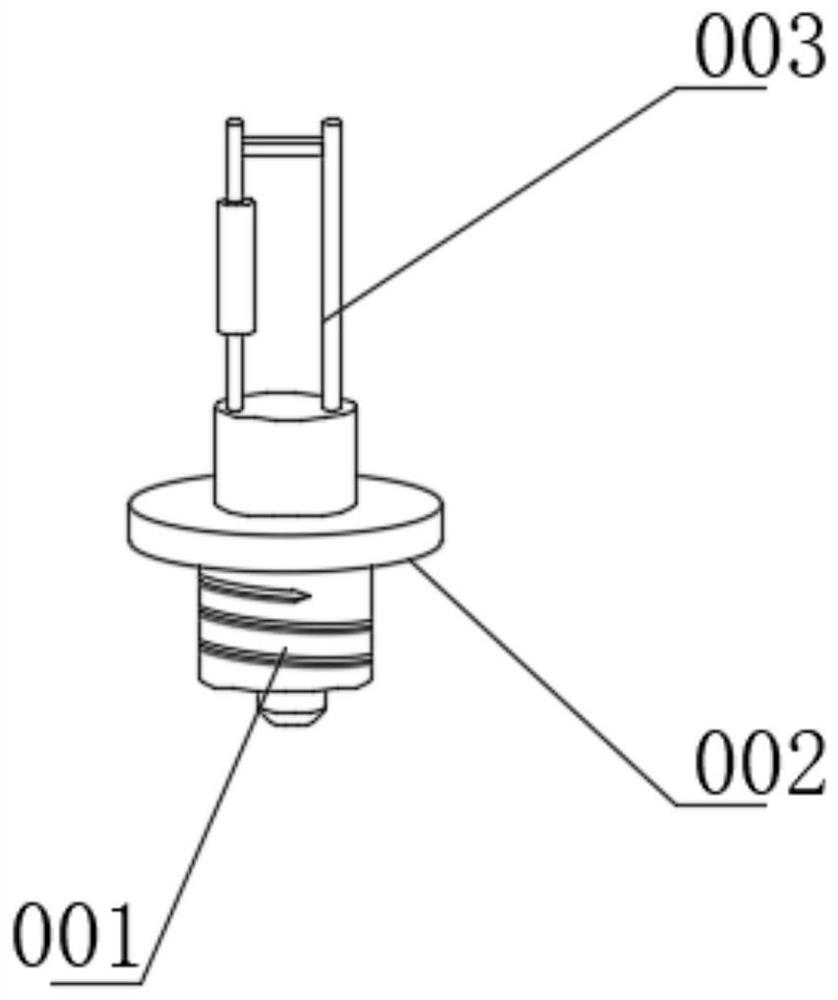

[0039] refer to figure 2, the semi-finished lamps include the socket 001; the lamp base 002;

[0040] In this embodiment, the number of limiting holes in a single fixture 13 is two, and the diameter of the limiting holes is adapted to the lamp base 002. During processing and production, the bottom end of the semi-finished product is inserted downward into the limiting holes, At this time, the lamp base 002 and the socket 001 are located at the top of the fixture 13 .

[0041] refer to Figure 4 combine Figure 5 , the top of the base 1 is slidably connected with a slide table 12, and a third cylinder 15 is installed on one side of the slide table 12, and the first conveyor belt 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com