Neutral oil and rust remover as well as preparation method and application thereof

A rust remover, neutral technology, applied in the field of oil and rust removal, can solve the problems of unrealistic industrial application, poor rust removal effect, low treatment efficiency, etc., and achieve good large-scale industrial production and use prospects, rust removal time The effect of short, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 3g fatty alcohol polyoxyethylene ether, add 100g pure water and ultrasonically dissolve to obtain a clear and transparent solution for later use; weigh HEDP-4Na 8g, citric acid 5g, EDPA-2Na 3g, sodium tripolyphosphate 3g, potassium chloride 3g, sulfur 1g of urea, 5g of formic acid, and 100g of pure water are ultrasonically dissolved to obtain a clear and transparent solution, and the volume ratio of the two is 1:1 to obtain a neutral degreasing and rust removing agent.

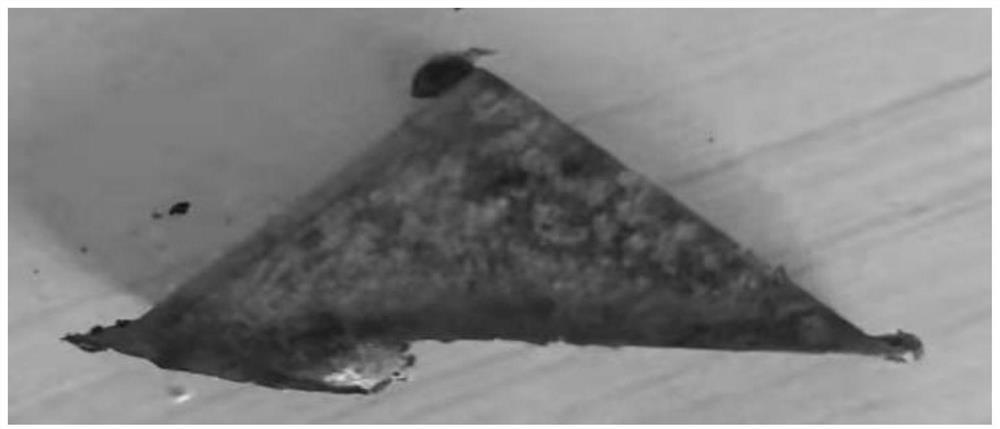

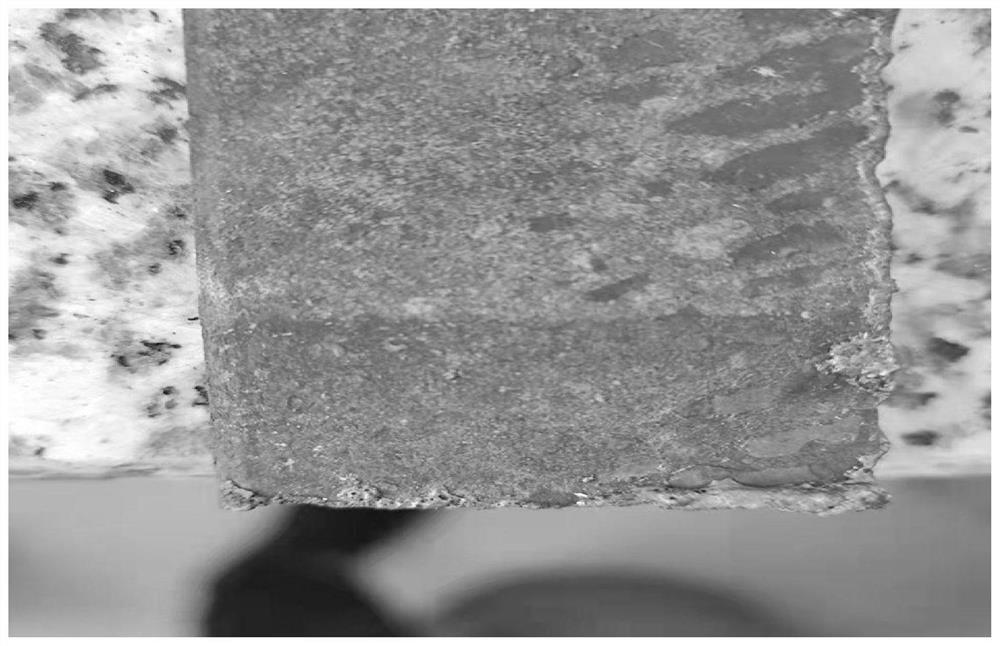

[0033] Use the above-mentioned neutral degreasing and derusting agent to soak lightly rusted parts at room temperature for 5 minutes. After the treatment, the derusting effect is good. See figure 1 and figure 2 .

[0034] Use the above-mentioned neutral degreasing and derusting agent to soak the heavily rusted parts for 5 minutes at room temperature by conventional means. After the treatment, the derusting effect is not ideal. See image 3 .

[0035] Using the above-mentioned neutral degreasin...

Embodiment 2

[0038] Weigh 3g of fatty alcohol polyoxyethylene ether, add 100g of pure water to ultrasonically dissolve to obtain a clear and transparent solution for later use; weigh 86g of HEDP-4Na, 4g of citric acid, 2g of EDPA-2Na, 1g of sodium tripolyphosphate, 2g of potassium chloride, sulfur Add 1g of urea, 4g of formic acid, and 90g of pure water to ultrasonically dissolve to obtain a clear and transparent solution, and the volume ratio of the two is 1:1 to form a neutral degreasing and rust removing agent.

Embodiment 3

[0040] Weigh 3g fatty alcohol polyoxyethylene ether, add 100g pure water and ultrasonically dissolve to obtain a clear and transparent solution for later use; weigh HEDP-4Na 10g, citric acid 6g, EDPA-2Na 5g, sodium tripolyphosphate 4g, potassium chloride 5g, sulfur Add 3g of urea, 7g of formic acid, and 130g of pure water to ultrasonically dissolve to obtain a clear and transparent solution, and the volume ratio of the two is 1:1 to obtain a neutral degreasing and rust removing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com