Multistage adsorption polymer fluid loss agent and preparation method thereof

A fluid loss reducing agent and polymer technology, which is applied in the field of oilfield chemicals and oil well cementing admixtures, can solve the problems of single molecular weight distribution, single adsorption strength, and lack of universality, and achieve good temperature resistance, The effect of preventing negative effects and good steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

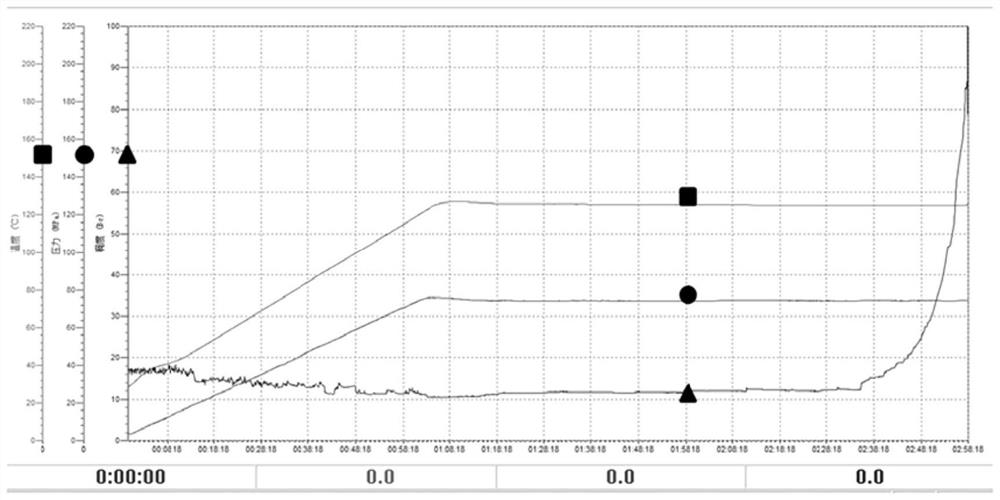

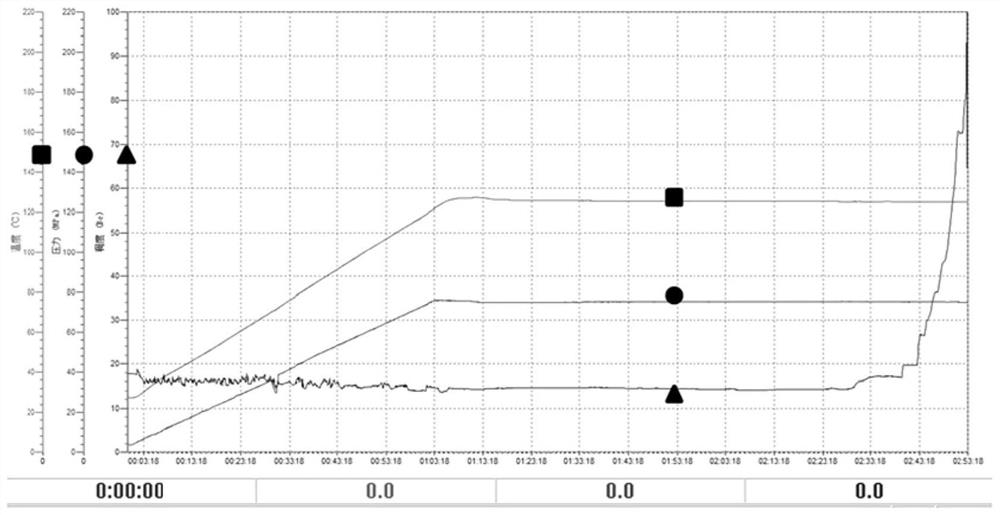

Image

Examples

Embodiment 1

[0055] This example provides a multi-stage adsorption polymer fluid loss reducer and its preparation method. It is composed of three polymers with different adsorption strengths. In terms of weight percentage, it includes 55% of binary copolymers and 30% of terpolymers. %, 15% tetrapolymer, stirred at 50°C for 30min and mixed evenly.

[0056] The preparation method of the binary copolymer comprises the following steps: by weight percentage, the total amount is 100%, the balance is water, 15% of 2-acrylamide-2-methylpropanesulfonic acid, N,N- Diethylacrylamide 7%, dissolve in water, mix and stir evenly, then add 2.4% sodium hydroxide to adjust the pH value to 5.4~6.0, transfer it to a four-necked flask, heat up to 40°C~50°C, add 0.02% Dodecyl mercaptan, pass through inert gas protection, then prepare 0.08% initiator tert-butyl hydroperoxide / sodium metabisulfite to make an aqueous solution with a mass concentration of 15%, add dropwise, continue to stir and react for 2 to 3 hour...

Embodiment 2

[0061] This example provides a multi-stage adsorption polymer fluid loss reducer and its preparation method, which is composed of three polymers with different adsorption strengths, including 50% of binary copolymers and 38% of terpolymers by weight percentage. %, 12% tetrapolymer, stirred at 50°C for 30min and mixed evenly.

[0062] The preparation method of the binary copolymer comprises the following steps: by weight percentage, the total amount is 100%, and the balance is water. Dissolve 18% of 2-acrylamido-2-methylpropanesulfonic acid and 8% of N,N-dimethylacrylamide in water, mix and stir evenly, then add 2.6% sodium hydroxide to adjust the pH value to 5.4~ 6.0, transfer to a four-neck flask, heat up to 40°C-50°C, add 0.025% dodecyl mercaptan, pass through inert gas protection, and then prepare 0.06% initiator tert-butyl hydroperoxide / sodium metabisulfite Add dropwise an aqueous solution with a mass concentration of 15%, and continue to stir and react for 2 to 3 hours t...

Embodiment 3

[0067] This embodiment provides a multi-stage adsorption polymer water loss reducer and a preparation method thereof, which is composed of three kinds of polymers with different adsorption strengths, including 46% of the binary copolymer and 34% of the terpolymer in terms of weight percentage. %, tetrapolymer 20%, stir for 30min at 50°C and mix well.

[0068] The preparation method of the binary copolymer includes the following steps: by weight percentage, the total amount is 100%, and the balance is water. Dissolve 2-acrylamido-2-methylpropanesulfonic acid 21% and N,N-dimethylaminoethyl methacrylamide 12% in water, mix and stir evenly, and then add 3.1% sodium hydroxide to adjust The pH value is 5.4~6.0, transfer to a four-necked flask, heat up to 40℃~50℃, add 0.035% dodecyl mercaptan, pass into inert gas protection, and then peroxidize 0.12% initiator tert-butyl Hydrogen / sodium metabisulfite is prepared into an aqueous solution with a mass concentration of 15% and added dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com