Circuit board film tearing device

A circuit board and film device technology, applied in the directions of printed circuit, printed circuit manufacturing, packaging, etc., can solve the problems of circuit board damage, inconvenient circuit board automatic tearing film, inconvenient energy-saving operation, etc., to reduce energy consumption and facilitate Clamping, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

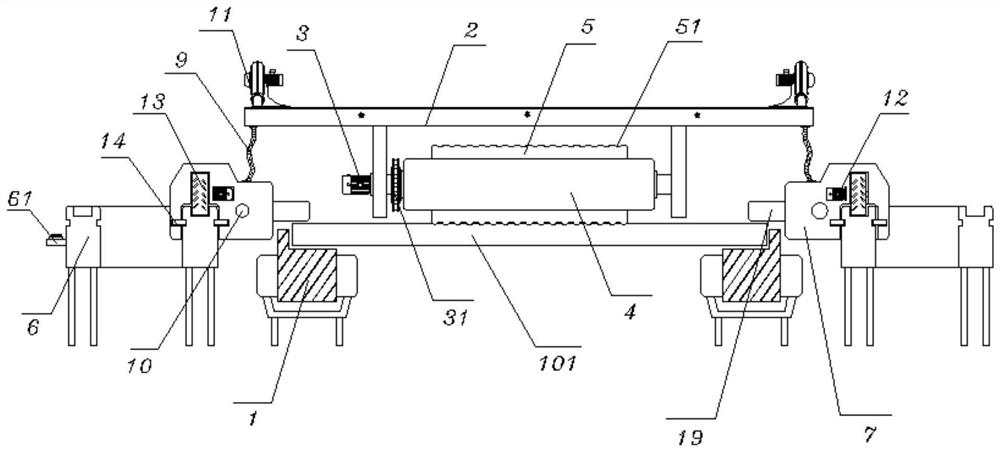

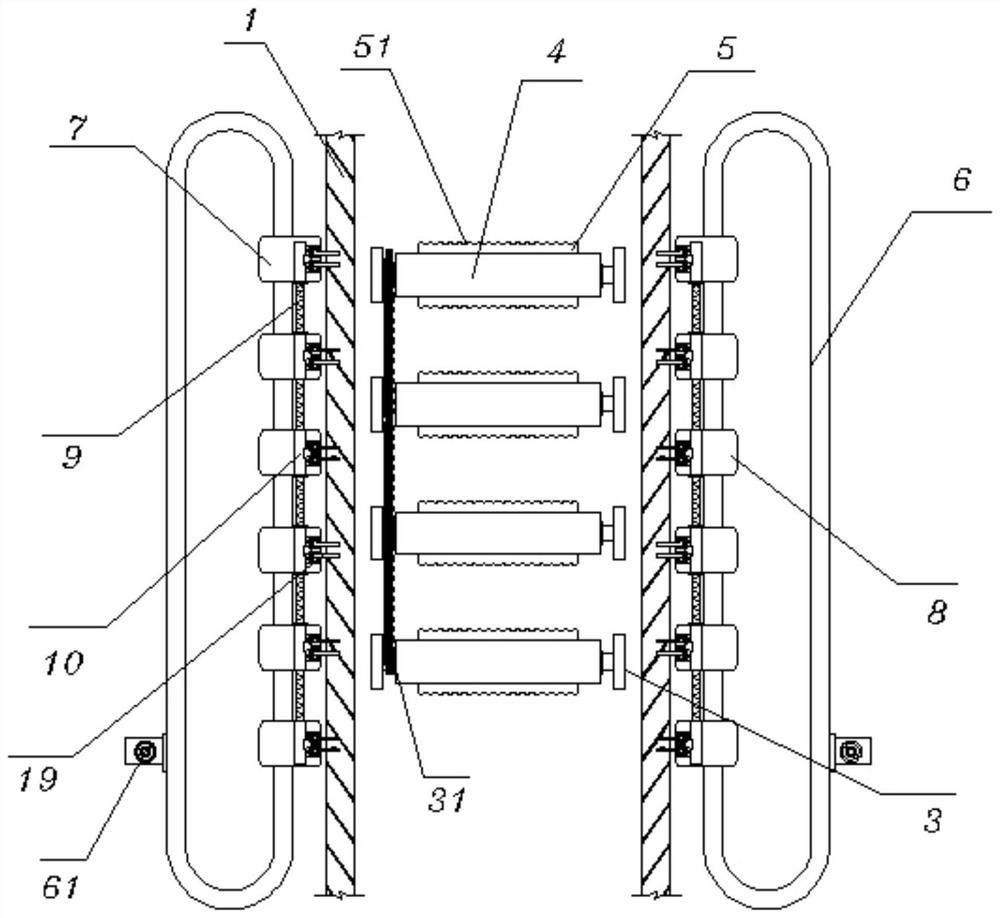

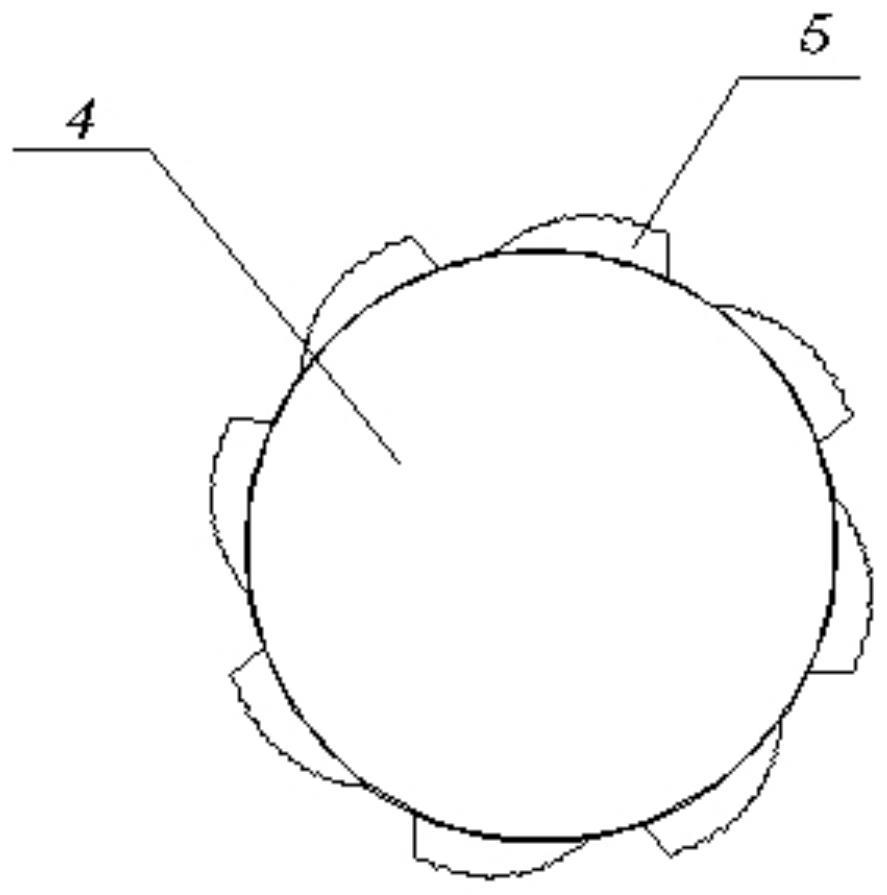

[0029] see Figure 1-4, including a transmission belt 1, the transmission belt 1 is distributed on both sides in a strip-shaped convex structure, and a circuit board 101 is placed on the transmission belt 1, and the two ends of the transmission belt 1 are provided with mounting brackets 2; it also includes: the first Motor 3, the first motor 3 is fixed on the side of the mounting frame 2, and the output end of the first motor 3 is connected with a tearing film roller 4, and the tearing film rollers 4 are connected by a chain 31, and the tearing film roller 4 Tear film strips 5 are fixed on the outer side, and the tear film strips 5 are equiangularly distributed on the tear film rollers 4, and the tear film strips 5 are designed in an arc-shaped convex structure, and the tear film rollers 4 are equidistantly distributed on the bottom of the mounting frame 2, Moreover, the height of the tearing film roller 4 increases successively along the transmission direction of the conveyor...

Embodiment 2

[0031] see Figure 1-2 and Figure 5 , the guide rail 6, the guide rail 6 is fixed on the ground, and the guide rail 6 is located on both sides of the conveyor belt 1, and the guide rail 6 is provided with a laminated vehicle head 7 and a laminated film vehicle body 8, and an infrared sensor 61 is fixed on the outside of the guide rail 6 A connecting hose 9 is provided between the clamped headstock 7 and the clamped vehicle body 8, and a pressure passage 10 is provided in the clamped headstock 7 and the laminated vehicle body 8, and the pressure passage 10 and the connecting hose 9 are connected to each other. The top of hose 9 runs through and is connected to the output end of air pump 11, and air pump 11 is fixed on the top edge place of mounting frame 2, and the second motor 12 is embedded in the clamping headstock 7, and the output of second motor 12 The end is connected with traveling roller 13, and both sides of the inner wall of the laminated vehicle head 7 and the lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com