Intelligent packaging machine for batch production of ziplock bags

A mass production and intelligent packaging technology, applied in packaging and other directions, can solve problems such as easy adhesion, plastic melting of ziplock bags, and ziplock bags that do not meet production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

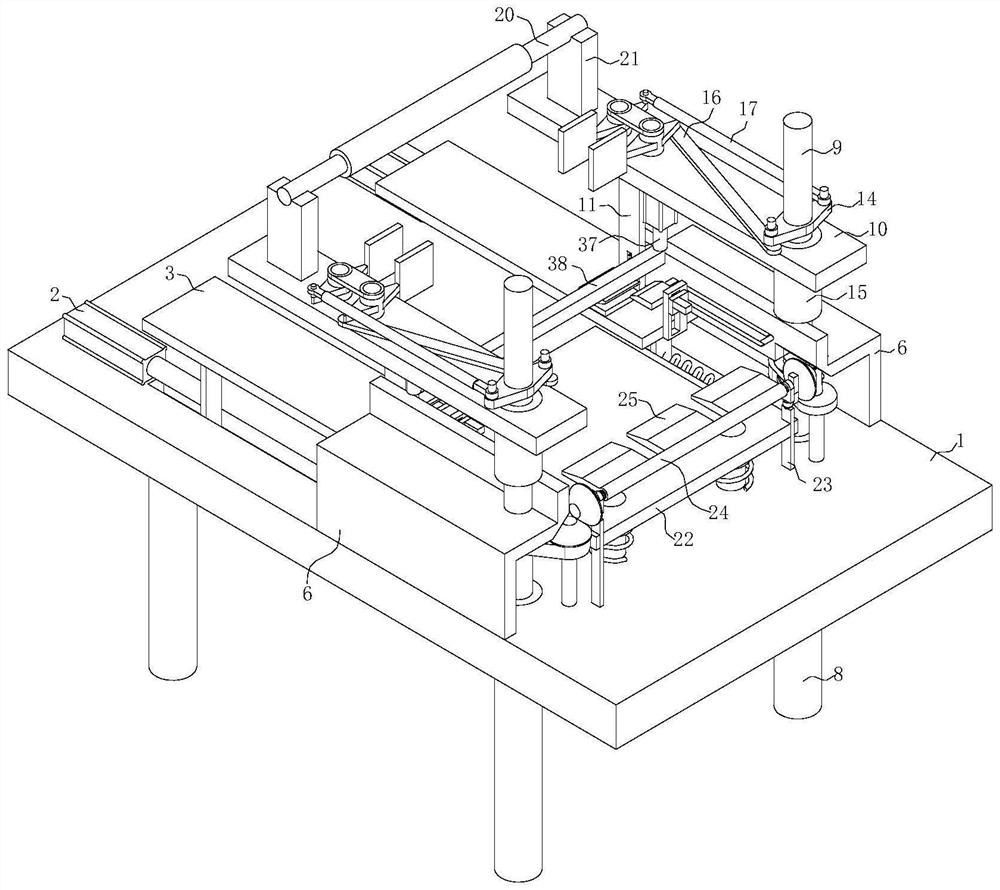

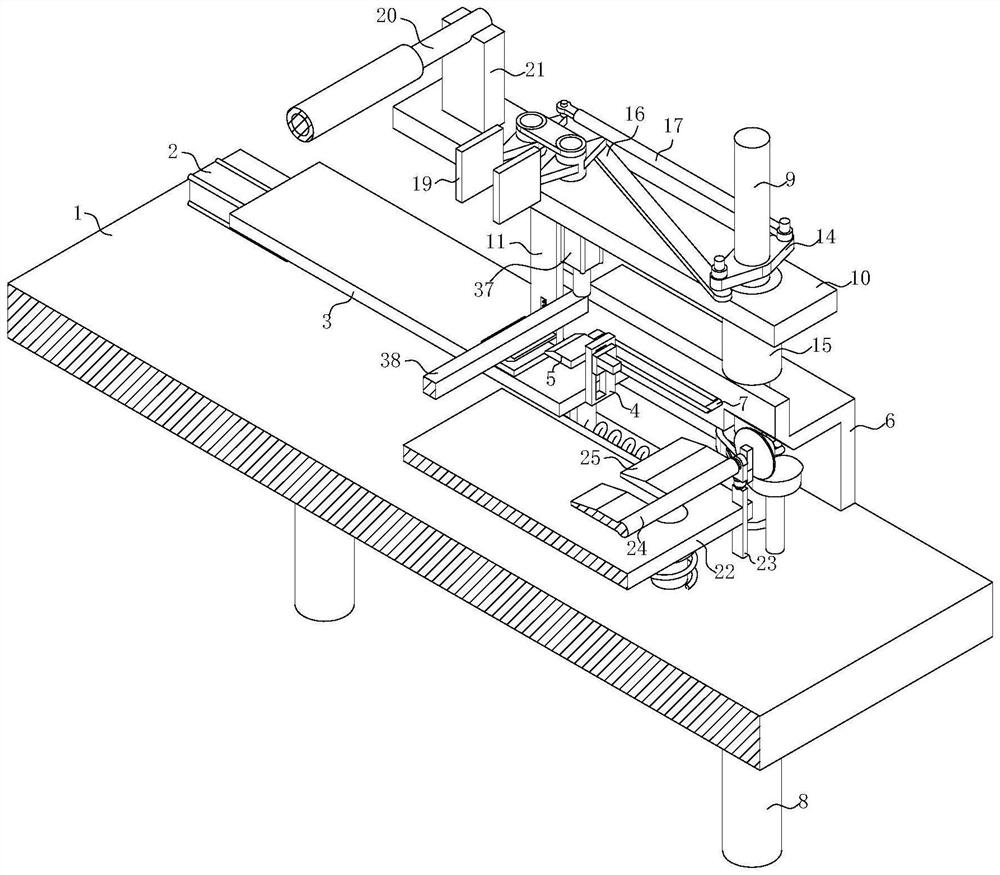

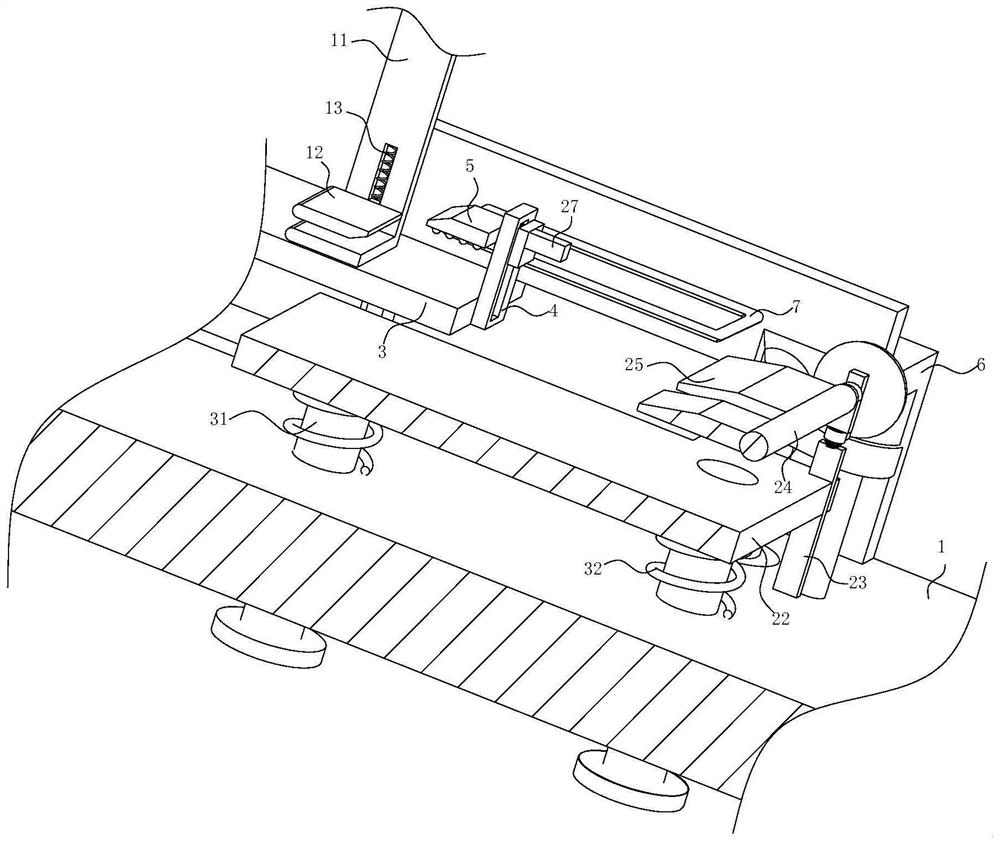

[0025] see Figure 1-7 , the present invention provides a technical solution: an intelligent packaging machine for batch production of self-sealing bags, including an operation table 1, a pole 8 is fixedly connected to the operation table 1, and a leveling transport mechanism is arranged above the operation table 1 , the right side of the leveling transport mechanism is provided with an accumulative clamping part, and the top of the leveling transport mechanism is provided with a cutting assembly. Cut the ziplock bag on the flat transport mechanism.

[0026] The leveling transport mechanism includes two symmetrically arranged first cylinders 2 and movable rods 9 on the console 1, the output ends of the first cylinders 2 are fixedly connected with push frames 3, and the ends of the push frames 3 A connecting block 4 is fixedly connected, and the connecting block 4 is slidably connected with a first splint 5. A first fixing plate 6 is arranged on the outside of the first splint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com