Integrated expansion kettle, heat management system and electric vehicle

A technology of thermal management system and expansion kettle, which is applied to electric vehicles, electric power devices, circuits, etc., can solve the problem of low integration of expansion kettles, and achieve the effects of saving layout space, reducing weight and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

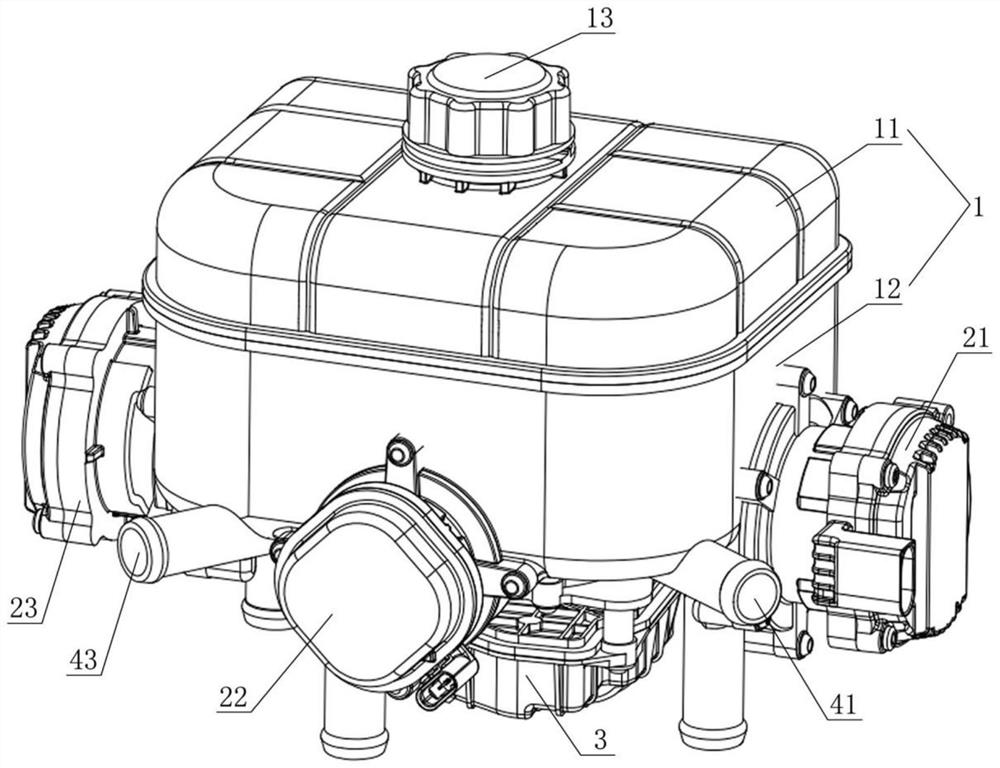

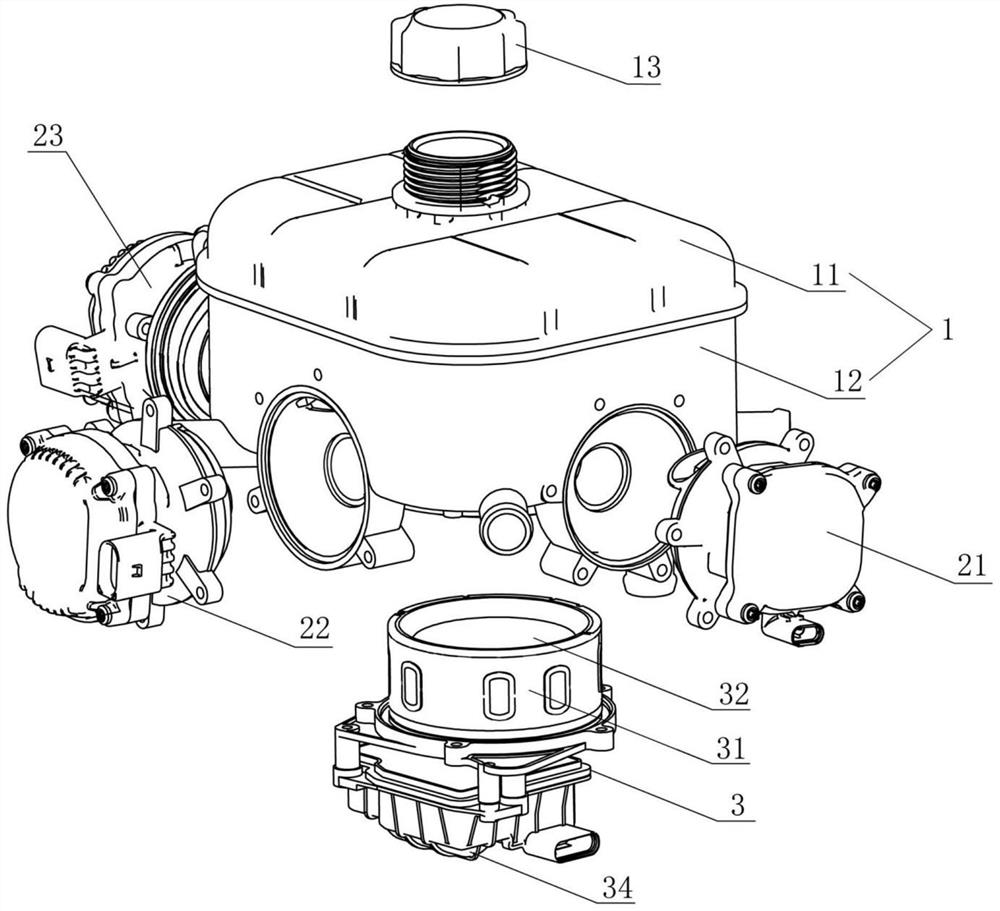

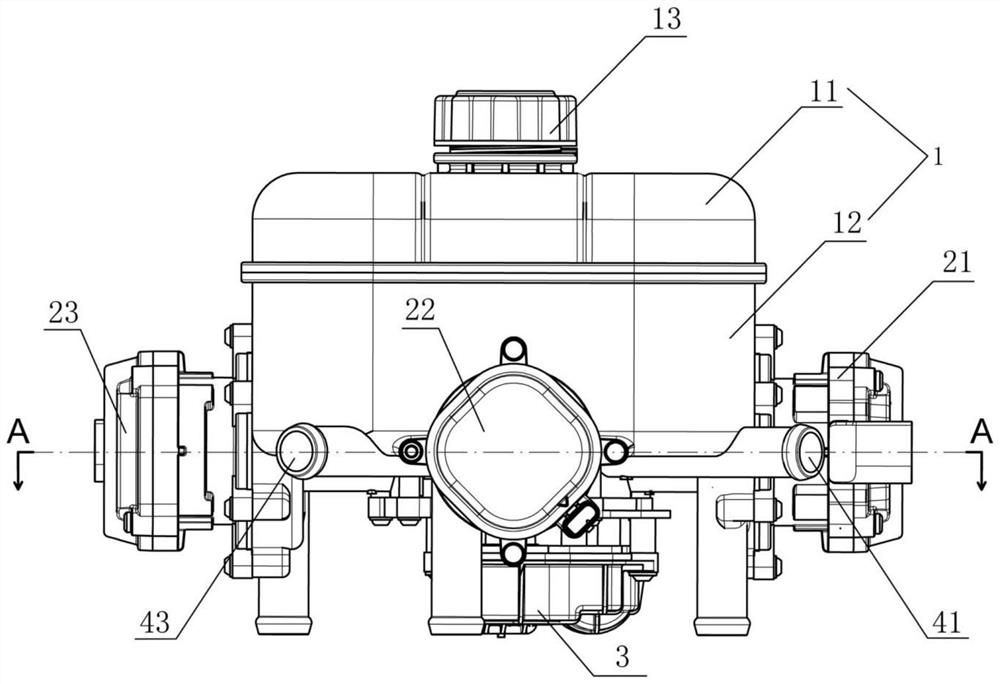

[0067] refer to Figure 1-Figure 4 , this embodiment is used to provide an integrated expansion kettle, including a kettle body 1 , a multi-way valve 3 arranged at the bottom of the kettle body 1 , a water pump group and a channel group arranged on the casing of the kettle body 1 .

[0068] The kettle body 1 includes an upper kettle body 11 and a lower kettle body 12 , and the lower kettle body 12 is located below the upper kettle body 11 . The upper pot body 11 and the lower pot body 12 can be fixed by hot-melt welding, and in some optional embodiments, the upper pot body 11 and the lower pot body 12 can also be fixedly connected by fasteners. The top of the upper pot body 11 is provided with a filling port for filling the interior of the kettle body 1 with cooling liquid, and the filling port is provided with a pot cover 13 capable of thread sealing.

[0069] The bottom of the kettle body 1 is provided with a multi-way valve 3, and the top of the multi-way valve 3 is provid...

Embodiment 2

[0094] refer to Figure 6 , this embodiment is used to provide a thermal management system, including the integrated expansion kettle as described in Embodiment 1, a passenger compartment heating system 5 communicated with the expansion kettle, a battery thermal management system 6, and a motor electronically controlled cooling system 7, and a control module for thermal management control.

[0095] The passenger compartment heating system 5 is used to heat the passenger compartment, including a high-voltage electric heater 51 (HVH, High Voltage Heater), and a warm air core 52. The warm air core 52 is arranged at the passenger compartment, and its pipelines are arranged in sequence according to the flow direction of the coolant. It communicates with the second water pump 22 , the high-voltage electric heater 51 , the warm air core 52 and the first channel 41 .

[0096] The battery thermal management system 6 is used to heat or cool down the battery pack 61, including a battery...

Embodiment 3

[0104] refer to Figure 7 , this embodiment is used to provide a thermal management system. Compared with Embodiment 2, the expansion kettle of this embodiment adopts working mode ten, the first channel 41 communicates with the fourth channel 44, and the second channel 42 communicates with the fourth channel. The three channels 43 are in communication, and the sixth channel 46 is in communication with the seventh channel 47 .

[0105] When the second water pump 22 and the third water pump 23 are working, the second water pump 22 drives the coolant to flow out from the second channel 42 , the temperature rises after flowing through the high-voltage electric heater 51 , and flows into the cooling fluid after flowing through the warm air core 52 The first channel 41 then flows into the fourth channel 44; the third water pump 23 drives the cooling liquid to flow out from the fourth channel 44, flows through the battery cooler 62 and the battery pack 61 in sequence, flows into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com