Efficient high-straightness cutting device for electrode foil

A technology of electrode foil and flatness, which is applied in metal processing and other directions, can solve the problems of low production efficiency, low flatness of battery pole piece cutting, and low precision of battery pole piece cutting, so as to improve cutting efficiency and cutting efficiency. The effect of cutting accuracy and improving positioning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

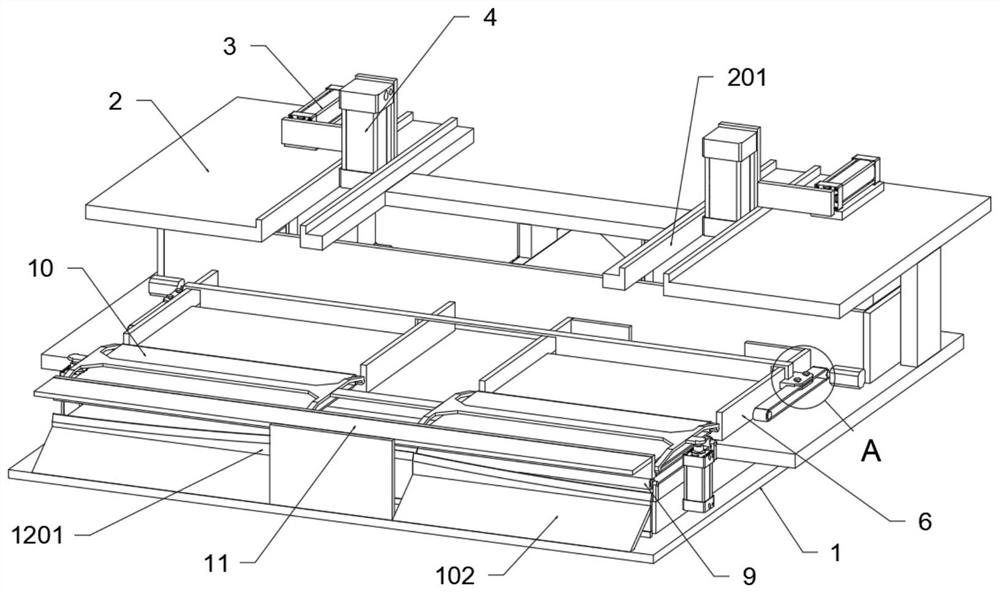

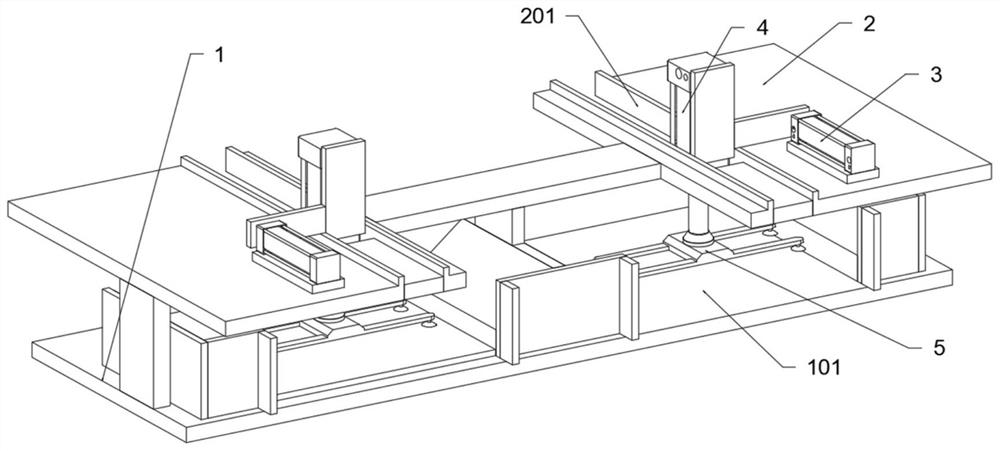

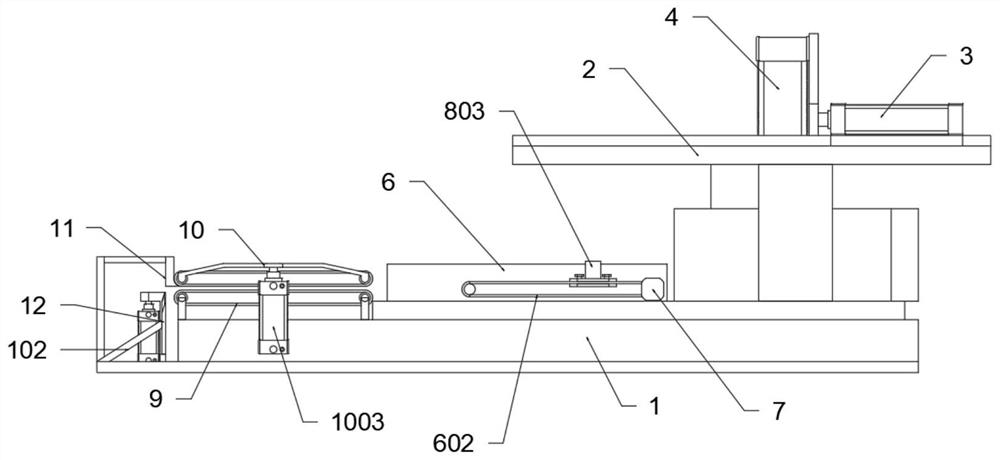

[0033] Example: Please refer to Figure 1 to Figure 8 :

[0034] The present invention proposes a high-efficiency high-flatness cutting device for electrode foil, including a cutting table 1; Two displacement telescopic drive parts 3 are connected, and the output ends of the two displacement telescopic drive parts 3 are fixedly connected to the suction cup lift drive part 4 through the bracket; the output end of the suction cup lift drive part 4 is fixedly connected with the suction cup frame 5; There are two places, and the two pushing tables 6 are all fixedly connected in the middle of the upper surface of the cutting table 1; the pushing driving part 7 is fixedly connected on the cutting table 1, and the output shaft of the pushing driving part 7 is connected and drives the outside of the pushing table 6 The propulsion drive belt 602; the propulsion frame 8 is slidably connected on the propulsion platform 6, and the two ends of the propulsion frame 8 are clamped by bolts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com