Method for manufacturing rigid-flex board with rigid board surrounded by flexible board

A technology of a rigid-flex board and a manufacturing method, which is applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of increasing the difficulty of process manufacturing and manufacturing cost, increasing the number of layers and thickness, and being unfavorable for mass manufacturing, so as to achieve mass manufacturing, The effect of reducing thickness and number of layers, improving production efficiency and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

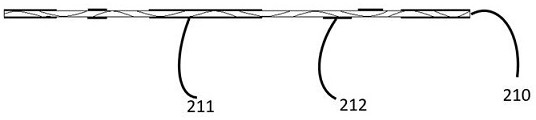

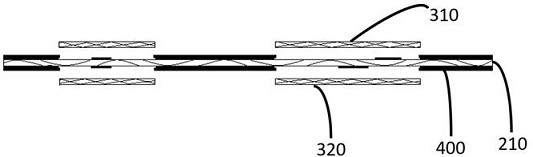

[0042] A rigid-flex board surrounded by soft boards, including a first inner hard board 110, an inner soft board 20 and a second inner hard board 120, the first inner hard board 110, the second inner The hard board 120 can be a single-sided, double-sided or multi-layer board, and the inner flexible board 20 can be a single-sided flexible board, double-sided flexible board or multi-layer flexible board; the inner flexible board 20 can be divided into The first inner flexible board 210 , the second inner flexible board 220 , the third inner flexible board, the fourth inner flexible board and the fifth inner flexible board.

[0043] The first inner hard board 110, the inner soft board 20, and the second inner hard board 120 are fixedly connected by a weak flow glue prepreg with a fluidity of less than 10%, and the glue fluidity of the weak flow glue prepreg is 3- 6%; the first prepreg 310 and the second prepreg 320 correspond to the first exposed area 211 of the soft board and th...

Embodiment 2

[0048] A rigid-flex board surrounded by soft boards, its structure is basically the same as that of Embodiment 1, the difference is that the first inner hard board 110 and the second inner hard board 120 are light boards without graphics near the prepreg.

[0049] The processing technology of the hard board surrounded by flexible boards in embodiment 2 is the same as that in embodiment 1.

Embodiment 3

[0051] A rigid-flex board surrounded by soft boards, its structure is basically the same as that of Embodiment 1, the difference is that the inner hard board 10 has a thickness of 0.7mm H / Hoz and does not contain copper.

[0052] The processing technology of the hard board surrounded by flexible boards in embodiment 3 is the same as that in embodiment 1.

[0053] The hard board produced by the manufacturing method of the present invention is surrounded by soft boards, which effectively solves the problem that the width of the soft board in the connection area between the soft board and the hard board is smaller than the width of the hard board, and increases the width of the soft board for wiring, which can effectively Reduce the thickness and number of layers of the board, reduce the difficulty of production, improve production efficiency and product yield, and then realize the overall effect of product quality improvement, product price reduction, and competitiveness improvem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com