Large-aperture voice coil with good heat dissipation performance

A heat dissipation performance and large-diameter technology, applied in the field of loudspeakers, can solve problems such as high voice coil temperature, poor heat dissipation effect, and burnt coils, so as to avoid excessive temperature, improve cooling effect, and realize automatic heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

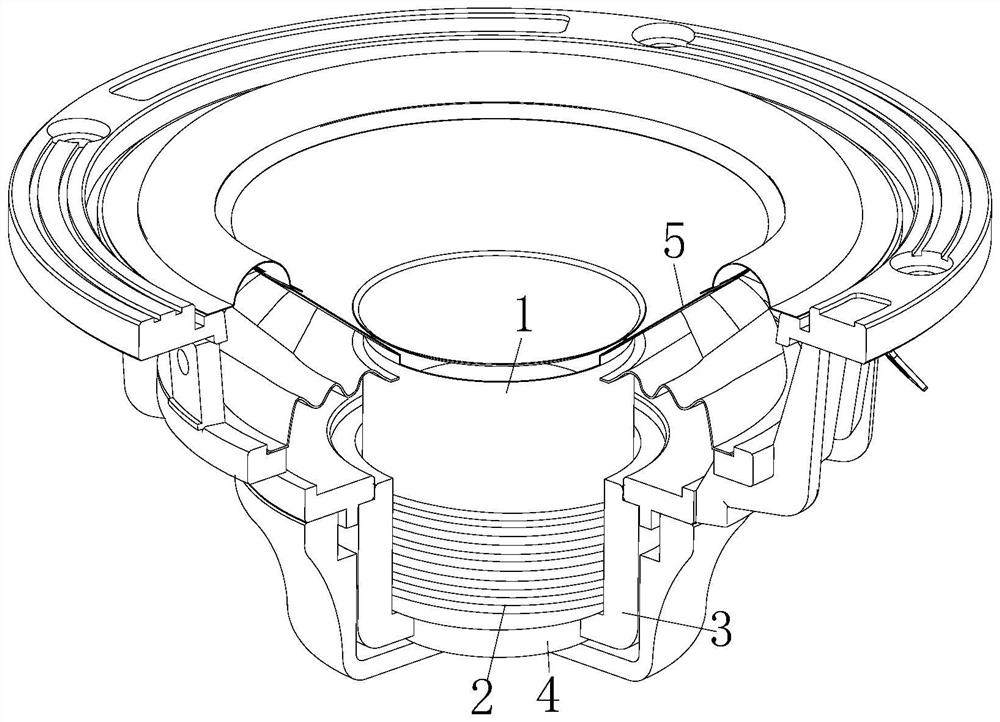

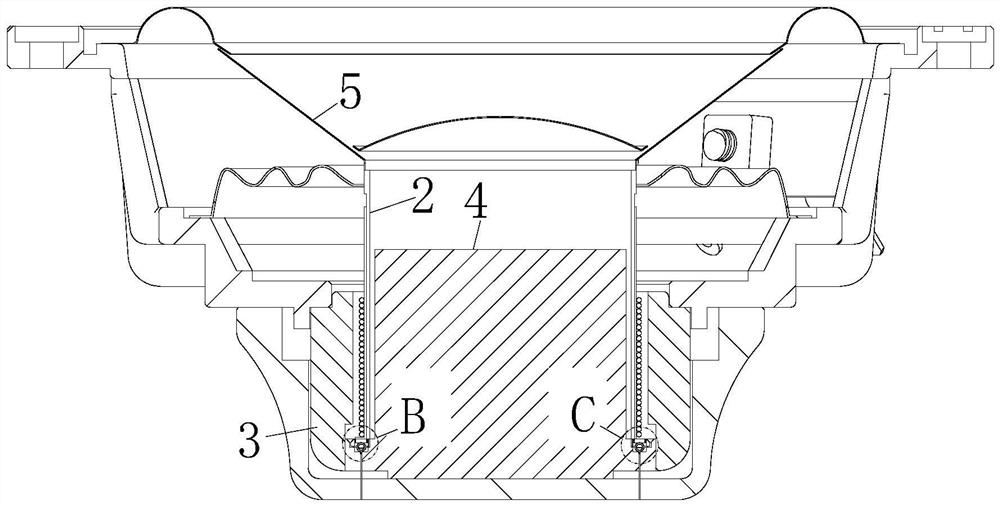

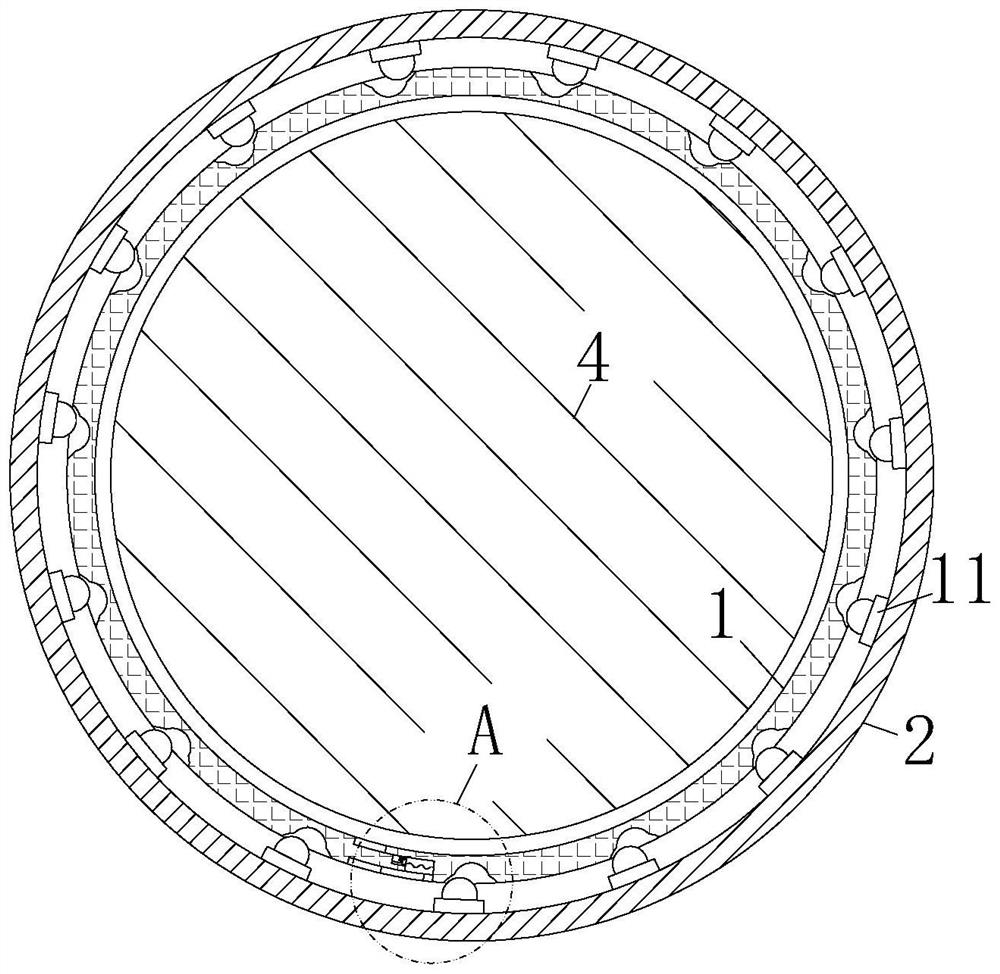

[0032] Such as Figure 1-Figure 4 As shown, a large-diameter voice coil with good heat dissipation performance described in the embodiment of the present invention includes a skeleton 1 and a coil 2; the skeleton 1 is arranged inside the frame; the inside of the frame is fixedly connected with a permanent magnet 3; T iron 4 is fixedly connected to the inner bottom surface of the basin frame; coil 2 is wound on the surface of the skeleton 1; a sound cone 5 is provided at the top of the skeleton 1; one side end surface of the skeleton 1 An interface 6 is provided, and the other side end face of the skeleton 1 is inserted into the interior of the interface 6; the interior of the interface 6 is fixedly connected with a first elastic piece 7; the first elastic piece 7 is designed as a memory alloy material; during work, by setting The first elastic piece 7, because the first elastic piece 7 is designed as a memory alloy material, when the internal temperature of the basin frame is ...

Embodiment 2

[0041] Such as Figure 8 As shown in Comparative Example 1, another embodiment of the present invention is: elastic connecting ropes 28 are firmly connected between the ball 12 and the groove bottom of the corresponding connecting groove 10; Rope 28, when the skeleton 1 shrinks, the position of the connecting groove 10 on the surface of the skeleton 1 will change, and the coil 2 will also drive the movement of the connecting strip 11. Therefore, when the temperature drops, it is difficult for the ball 12 to quickly guide into the connecting groove 10. Internally, the skeleton 1 is connected to the connecting strip 11, and even the continuous dislocation between the connecting groove 10 and the ball 12 causes the connecting strip 11 and the skeleton 1 to fail to connect normally. Through the elastic effect of the elastic connecting rope 28, the ball 12 can be normal. Lead into the interior of the corresponding connecting groove 10 to ensure that the coil 2 and the skeleton 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com