Chemical process pump with heat dissipation and shock absorption functions and method

A technology of process pumps and chemical industry, applied in springs/shock absorbers, components of pumping devices for elastic fluids, pumps, etc., can solve problems affecting heat dissipation rate, heat cannot be released quickly, etc., to avoid accumulation, Increased speed, the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

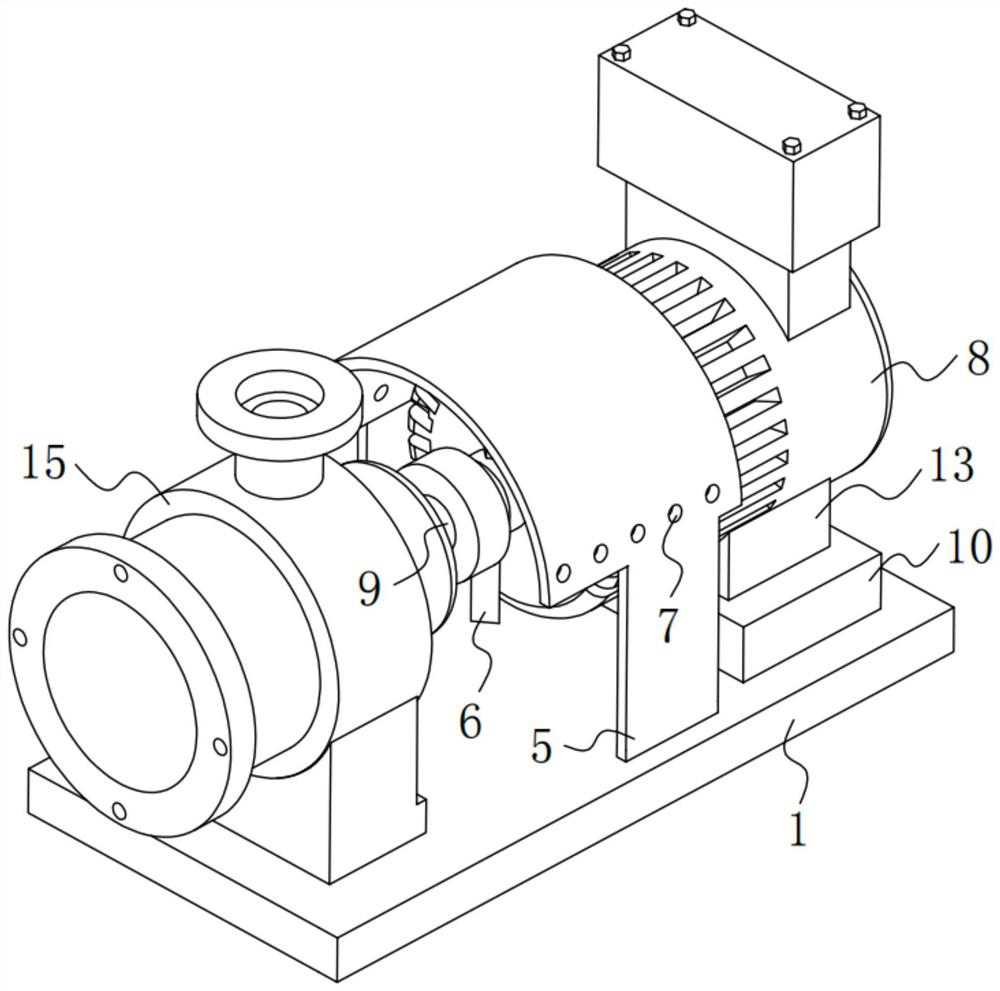

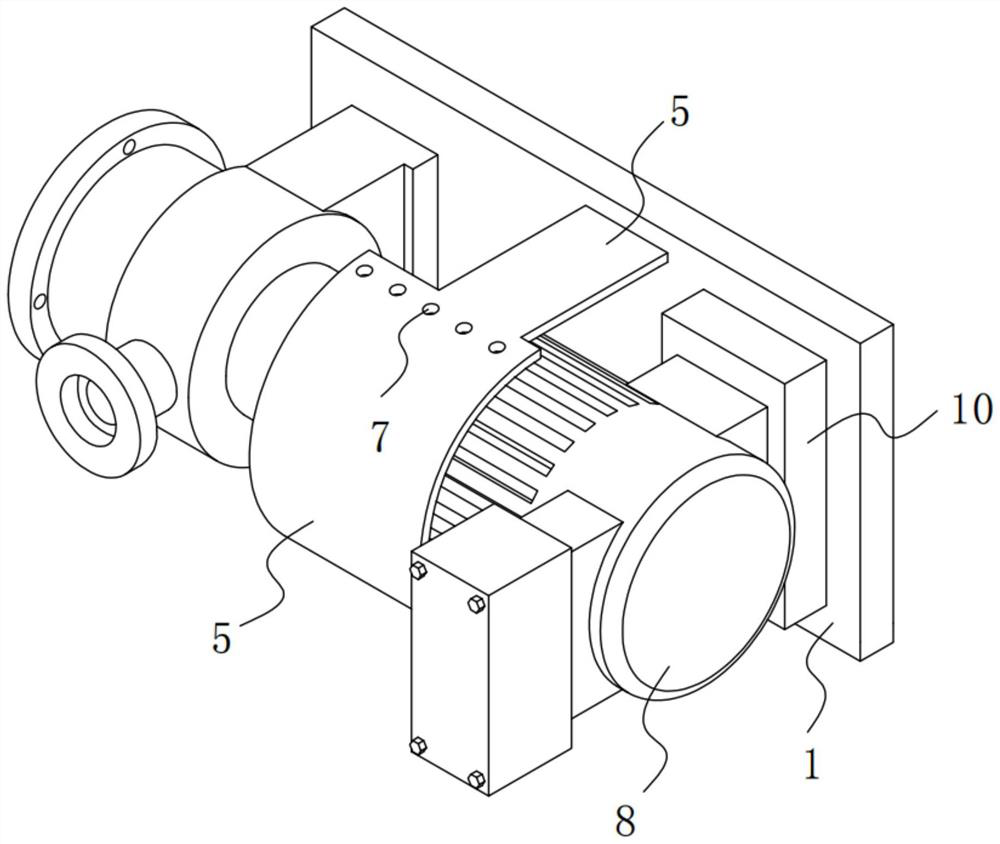

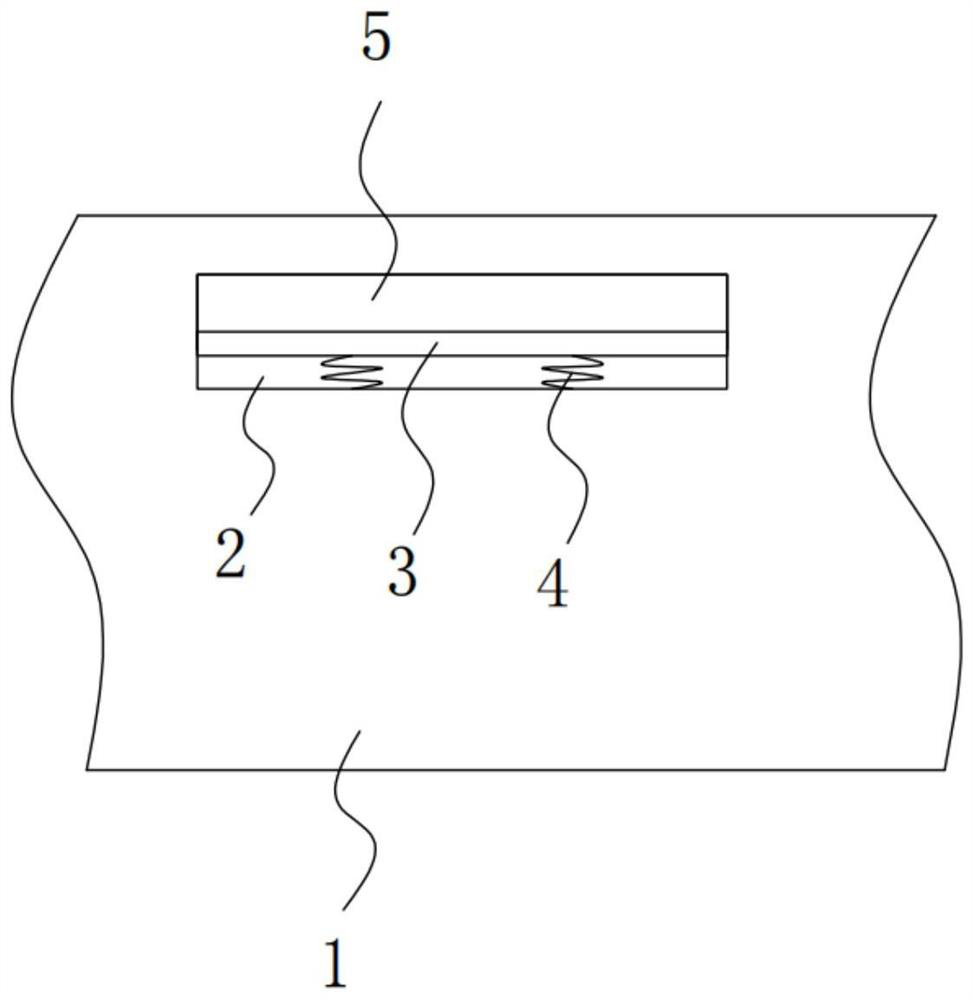

[0035] Please refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 ,in, figure 1 Schematic diagram of the structure of the first embodiment of the chemical process pump and method provided by the present invention with the function of heat dissipation and shock absorption; figure 2 for figure 1 Schematic diagram of the side view structure of the motor shown; image 3 for figure 1 A schematic cutaway view of the base shown; Figure 4 for figure 1 The schematic cross-sectional view of the box shown; Figure 5 for Figure 4 The partial enlarged schematic diagram at A is shown. A chemical process pump and method with heat dissipation and shock absorption functions, including:

[0036] base1;

[0037] The installation groove 2, the installation groove 2 is opened in the inside of the base 1, and a clamping plate 3 is slidably connected between the two sides inside the installation groove 2, and a limit spring is arranged on one side of the clamping plat...

no. 2 example

[0065] Please refer to Image 6 , Based on the chemical process pump and method with heat dissipation and shock absorption function provided in the first embodiment of the present application, the second embodiment of the present application proposes another chemical process pump and method with heat dissipation and shock absorption function. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0066] Specifically, the difference between the chemical process pump and the method provided by the second embodiment of the present application is that: the bottom of the base 1 is fixedly connected with a bottom box 20, and the two inside the bottom box 20 A moving plate 21 is slidably connected between the sides, and the bottom of the moving plate 21 is provided with a moving wheel 22 , and the bottom of the moving wheel 22 passes through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com