Multi-material fused light high-strength battery pack structure and design method thereof

A battery pack, multi-material technology, applied in structural parts, secondary batteries, battery caps/end caps, etc., can solve the problems of difficulty in taking into account strength and sealing reliability at the same time, and rarely consider lightweight, etc. Lower quality, lower cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

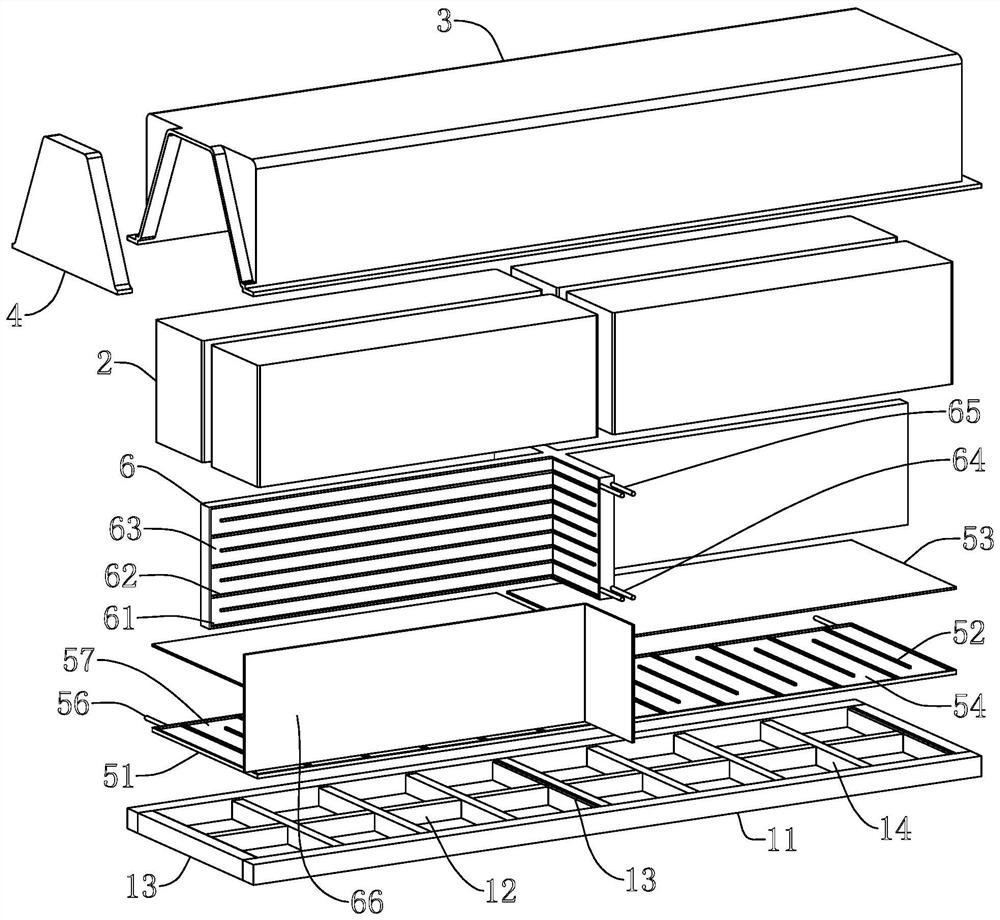

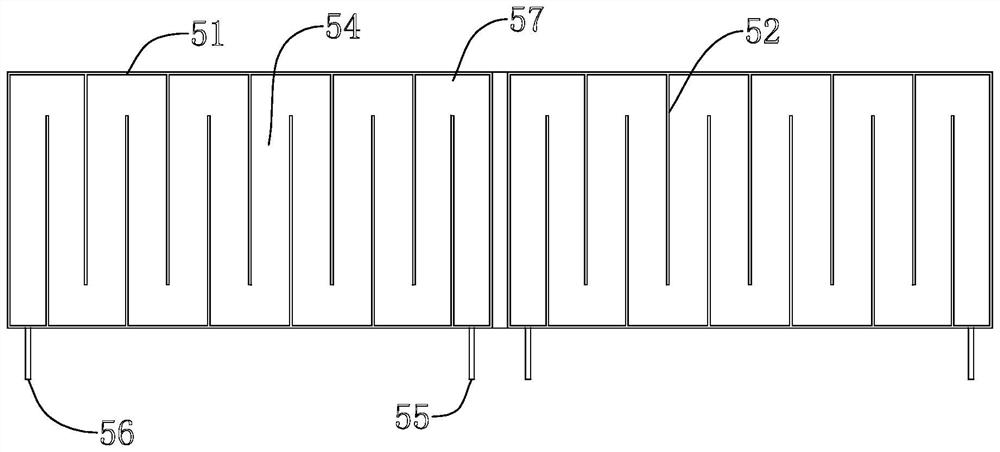

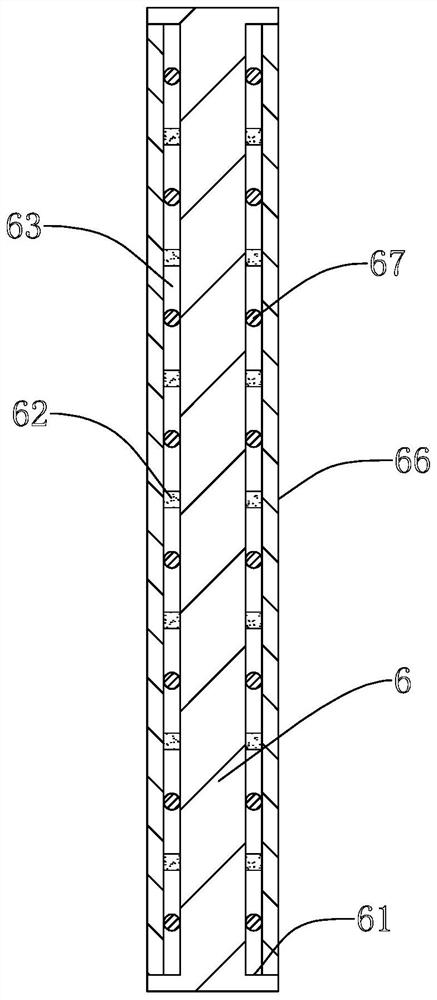

[0051] Embodiment, a multi-material fusion lightweight high-strength battery pack structure, such as Figure 1 to Figure 3 As shown, it includes a load-bearing frame, a battery module 2, an upper cover 3 and a plug-in board 4, the upper end of the load-bearing frame is provided with a cooling plate, the battery module 2 is arranged on the upper surface of the cooling plate, and the number of battery modules 2 is at least Two, specifically, the number of battery modules 2 in this embodiment is four, of course, it can also be two or five without affecting the protection scope of the present invention; A separator 6 is provided, and the separator 6 is made of heat insulating material. A first groove 61 is provided on any side of the separator 6 close to the battery module 2, and a plurality of first spacers are arranged in the first groove 61 62, the first spacer 62 divides the inner chamber of the first groove 61 into a continuous "S"-shaped first flow channel 63, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com