Sealing pressure maintaining system of two-stage screw compressor

A screw compressor and compressor technology, applied in the field of compressors, can solve the problems of inconvenient casting, inconvenient maintenance and maintenance, and mismatch of pressure requirements and pressures, so as to ensure the air tightness of the connection, improve the introduction efficiency, and facilitate production. casting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

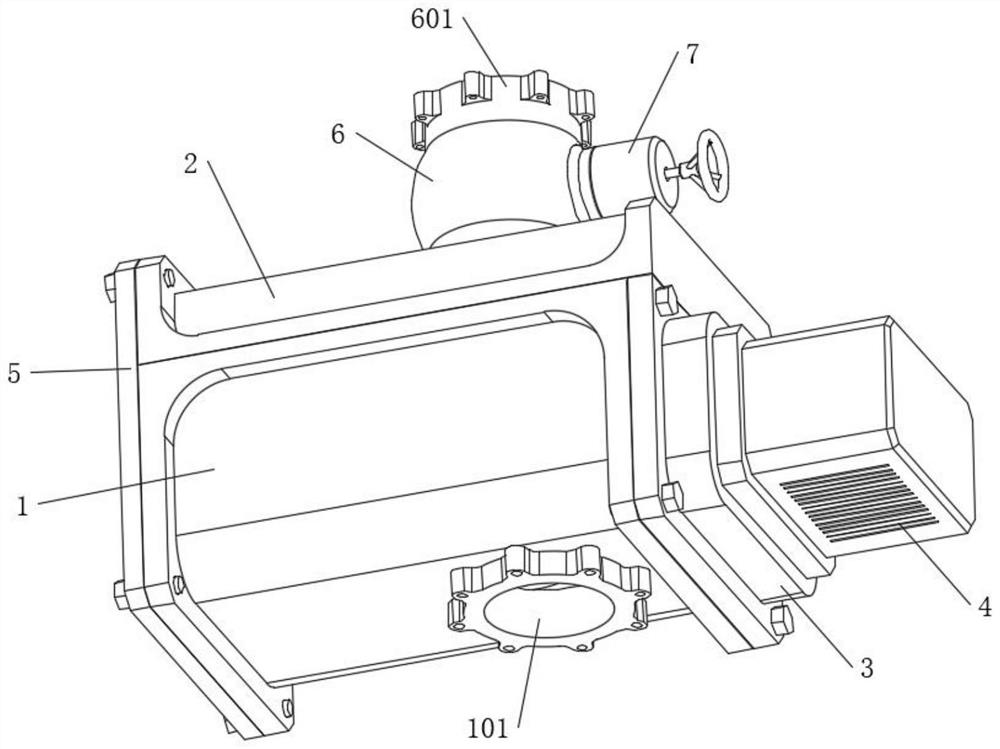

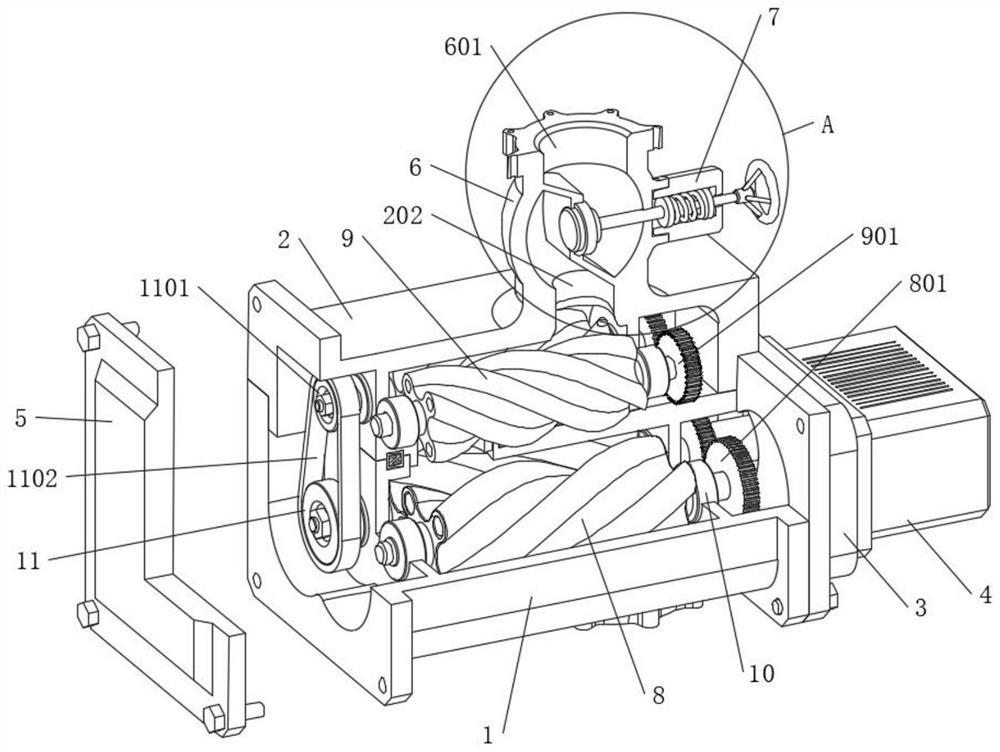

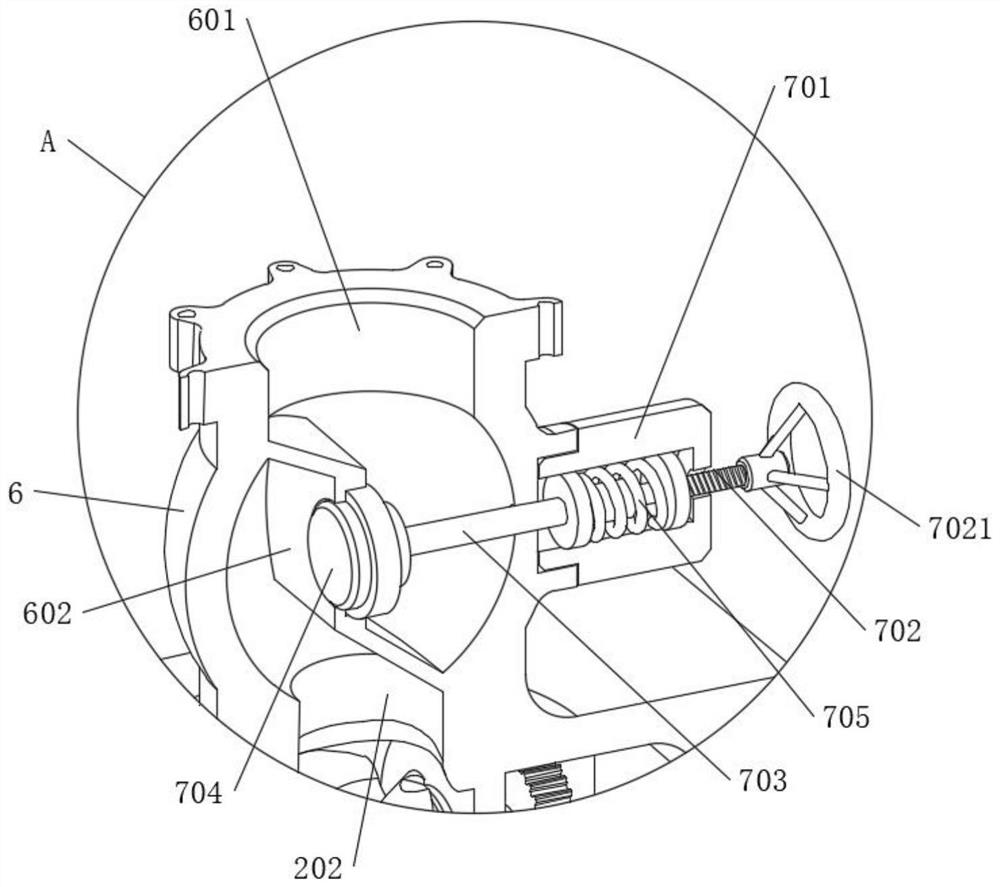

[0025] Please refer to Figure 1-Figure 6 , the present invention proposes a sealed and pressure-maintaining system for a two-stage screw compressor, including a compressor casing body, which consists of a first casing 1, a second casing 2, a first cover 3 and a second The cover 5 is assembled. The inside of the first casing 1 is provided with a pair of first-stage screw rotors 8 arranged in parallel, and the inside of the first casing 1 is provided with a first-stage air cavity matching the pair of first-stage screw rotors 8. One side of the first casing 1 is fixed with a first cover 3 by bolts, and the outer side of the first cover 3 is fixed with a motor 4 by bolts, and the output shaft of the motor 4 is connected to one shaft end of the first-stage screw rotor 8 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com