Experimental device and assembly method for studying failure mechanism of pile-rock interface

A technology of failure mechanism and experimental equipment, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of large bearing capacity, waste, and high test cost of rock-socketed piles, and achieve stable and reliable disassembly and debugging, and easy disassembly And the effect of easy debugging and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

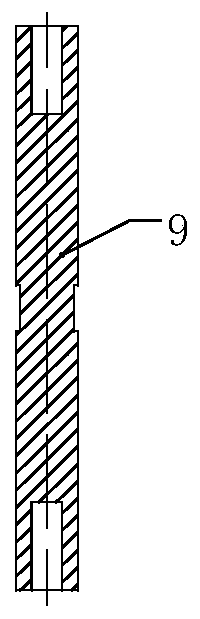

[0049] Such as Figure 19 and 20 As shown, the present invention is an experimental device for studying the failure mechanism of the pile-rock interface with a large-span two-way laminated slab, including an experimental box for placing experimental piles, a reaction frame above the experimental box, and a reaction frame and the experimental The jack 1 between the boxes, the upper surface of the jack 1 is fixed with the reaction force frame, and the lower surface is connected with the dowel bar 3 that can act on the experimental pile through the pressure sensor 2, and the dowel bar 3 is also connected with a displacement sensor 4.

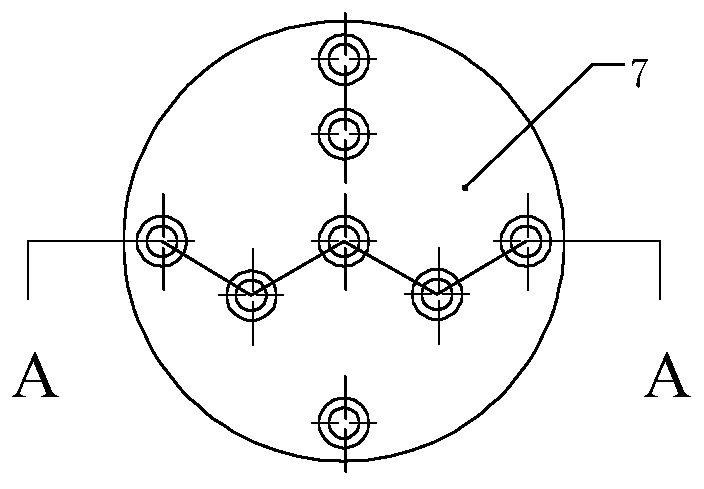

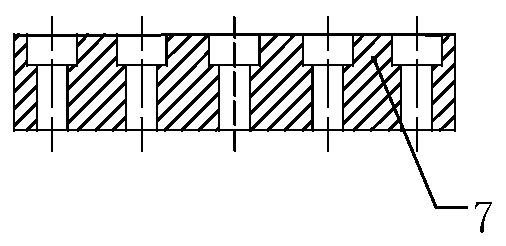

[0050] Such as Figure 17 As shown, the experimental box includes a hollow cylindrical cavity structure 5 with an I-shaped cross section and a bottom sealing plate 6 located below the cavity structure 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com