Processing device for colored textile threads

A processing device and textile thread technology, which is applied in the direction of textile material equipment configuration, spray/jet textile material treatment, liquid/gas/steam removal with squeeze rollers, etc., can solve the problem of unusable sewage, poor cooling effect, and refrigerant To achieve the effect of improving the utilization rate of cold air, accelerating the flow and increasing the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

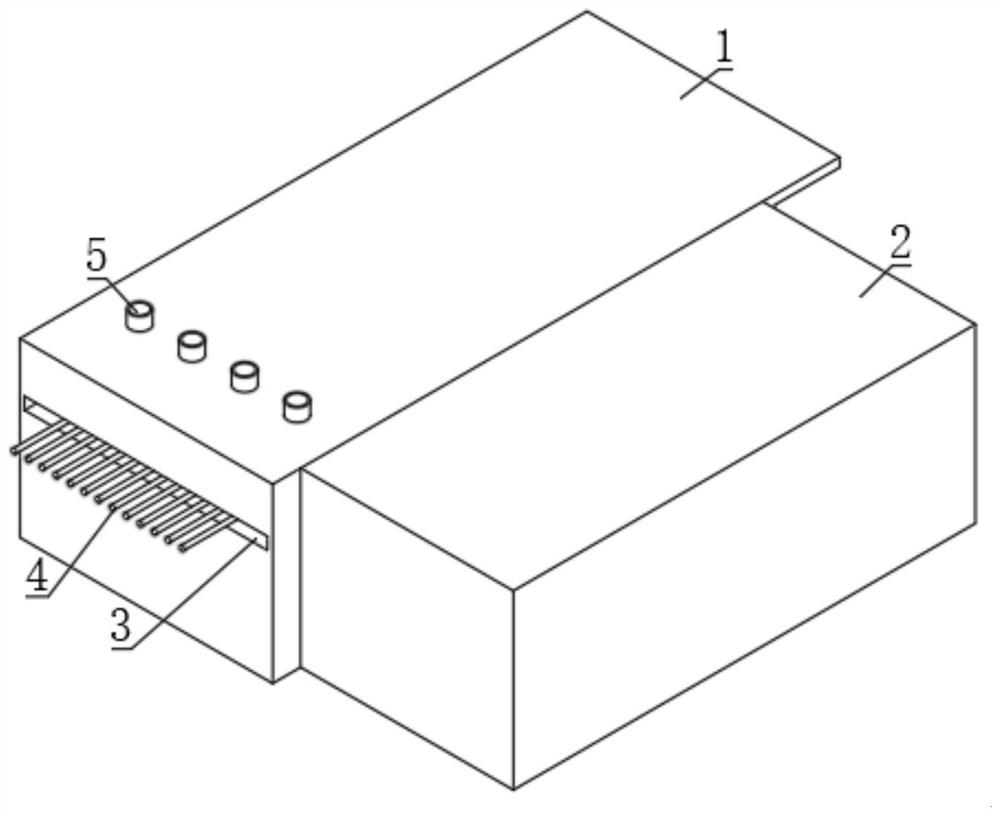

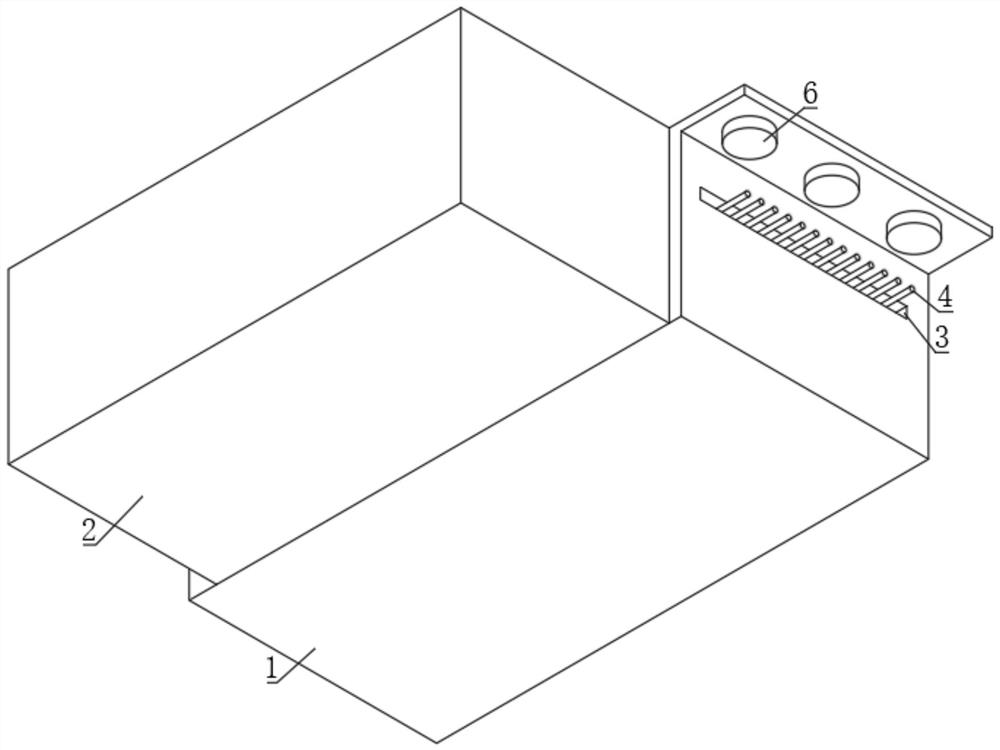

Image

Examples

Embodiment approach

[0045] A technical solution proposed by the present invention: providing a method for implementing a processing device with colored textile threads, comprising the following steps:

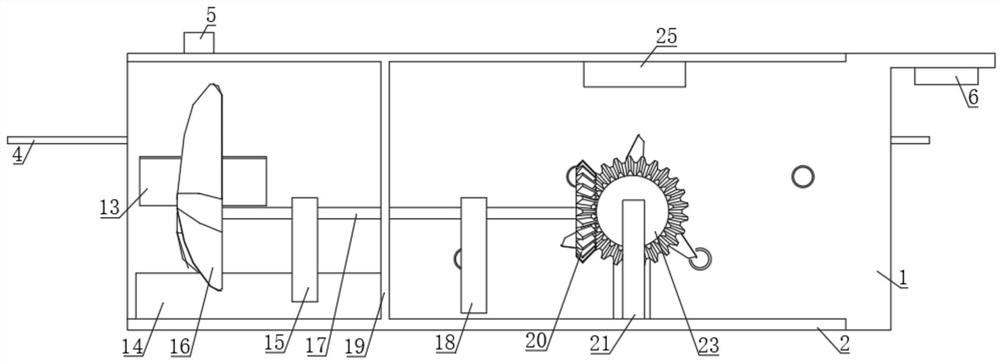

[0046] Step 1: When the textile thread 4 is transported to the conveying hole 3, the clear water passes through the nozzle 5 to initially cool the surface of the textile thread 4, and then the textile thread 4 is squeezed to discharge the water when it passes through the first roller 7 and the second roller 9, Then the textile line 4 is delivered to the input end of the cooling roller 11;

[0047] Step 2: The cooled water flows into the inclined water tank 12, and then flows out through the water outlet 13 to drive the water wheel 16 to rotate, and then drives the first bevel gear 20 to rotate, then drives the second bevel gear 23 to rotate, and finally drives the fan 24 to rotate, The refrigerant 25 starts to produce cold air, and the fan 24 rotates to blow the cold air into the third circular gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com