Convenient-to-replace ultrafiltration membrane device for industrial sewage treatment

A technology for industrial sewage and treatment devices, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, infiltration/dialysis water/sewage treatment, etc., can solve the problem of shortening the service life of internal components of equipment and reducing equipment filtration Efficiency, difficulty in replacing parts, etc., to achieve the effect of improving the convenience of cleaning, avoiding difficult cleaning, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

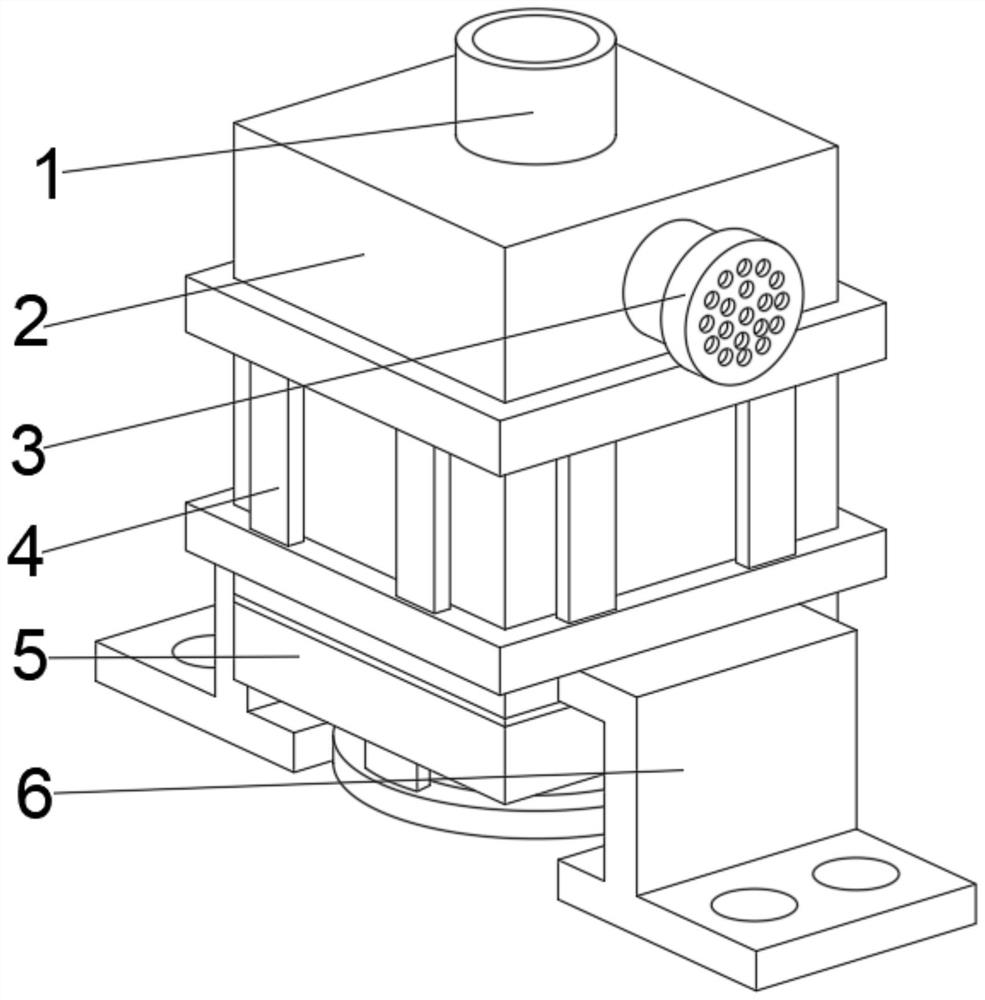

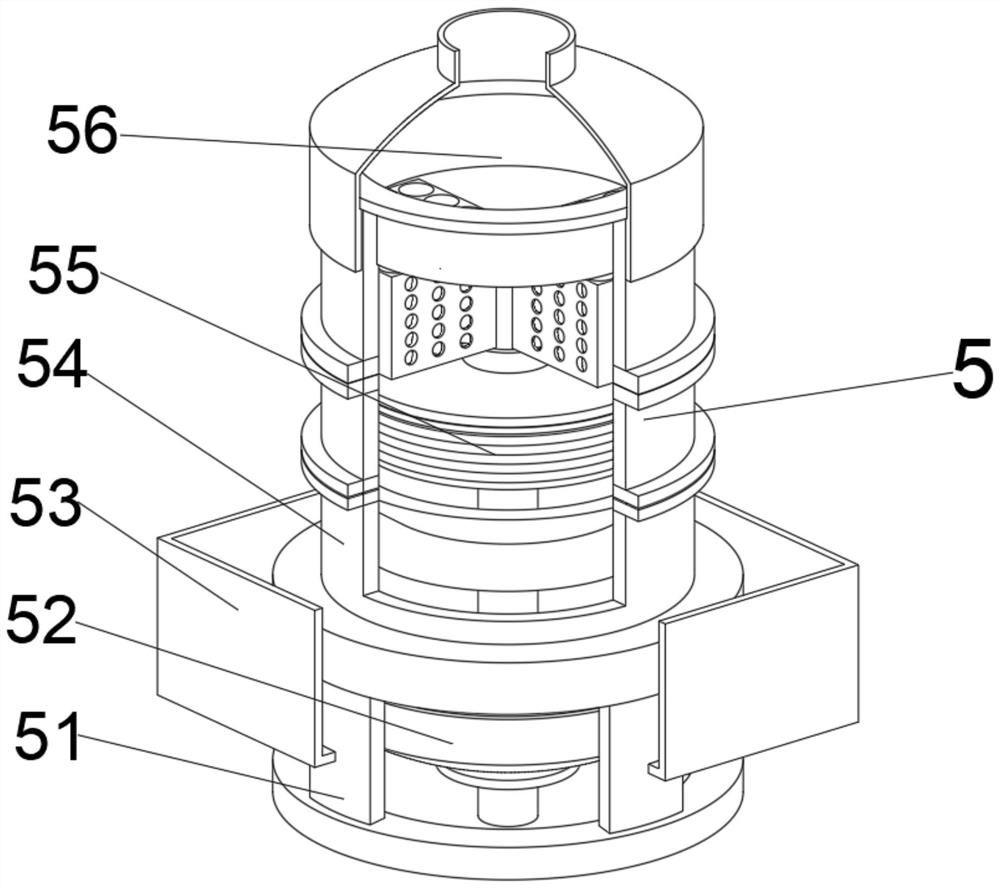

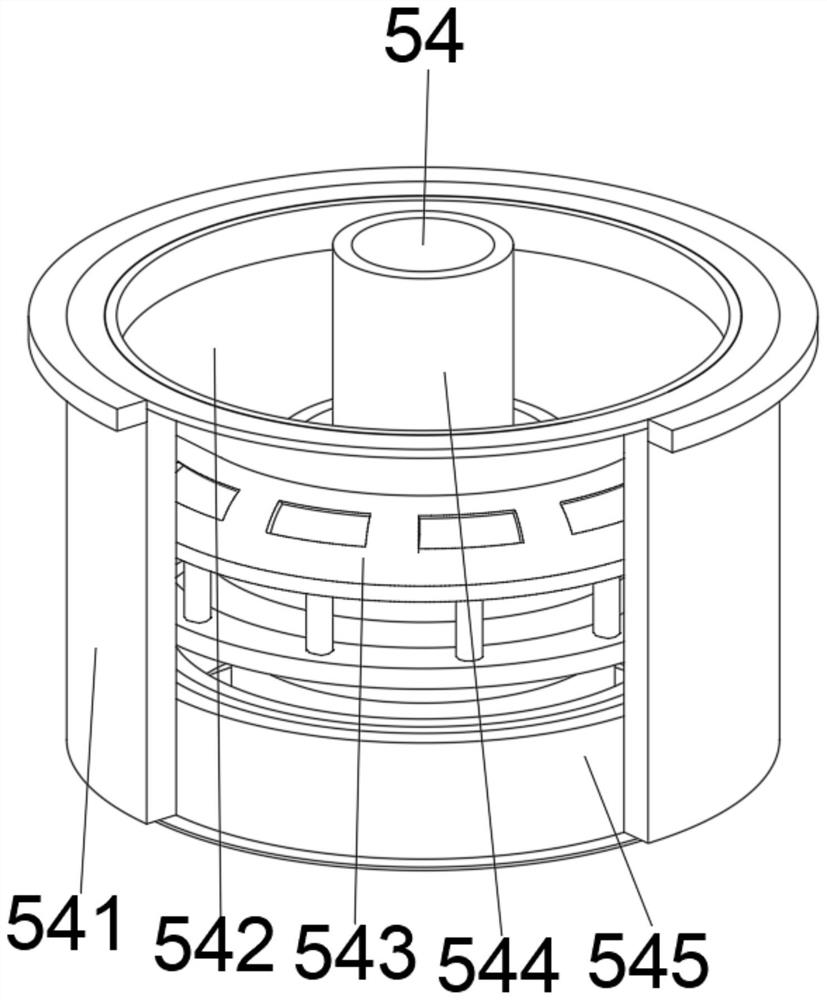

[0038] see Figure 1-6 , the present invention provides a technical solution: an ultrafiltration membrane device for industrial sewage treatment that is easy to replace, including a protective shell 2, the top middle of the protective shell 2 is connected to a water inlet pipe 1, and the right side of the protective shell 2 The middle position of the top of the outer wall is connected with an air outlet pipe 3, which communicates with the protective shell 2 through the air outlet pipe 3, so that the air outlet pipe 3 can discharge the gas inside the protective shell 2, effectively avoiding the gas inside the protective shell 2 due to long The pressure inside the protective shell 2 increases due to the inability to discharge time. The middle part of the outer wall on both sides of the protective shell 2 is fixedly connected with the clamping frame 4, and the middle position on both sides of the bottom of the clamping frame 4 is fixedly connected with a fixed connecting plate 6. ...

Embodiment 2

[0045] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using an ultrafiltration membrane device for industrial sewage treatment that is easy to replace, step 1: install the equipment, and connect the clamping frame 4 with the protection The housing 2 is fixedly connected, so that when the device is disassembled, the clamping frame 4 can be used to fix the device, and the clamping frame 4 is fixedly connected to the fixed connecting plate 6, thereby increasing the fixed area during disassembly;

[0046] Step 2: Filter the water flow through the filter cavity produced by the ultrafiltration membrane cartridge 55 and the flow guide device 56, and enter the support device 54 with the filtered water flow, communicate the support device 54 with the water outlet bottom cover 52, and place The support device 54 communicates with the ultrafiltration membrane cartridge 55, so that the water flow can be sealed and transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com