Ultraviolet curing device for annular sample of lining pipe and application of ultraviolet curing device

A curing device and lining pipe technology, which is applied in the direction of tubular objects, applications, household appliances, etc., can solve the problems of unfavorable experimental research, large material waste, and long time consumption, so as to reduce deviation, facilitate construction, and bind convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

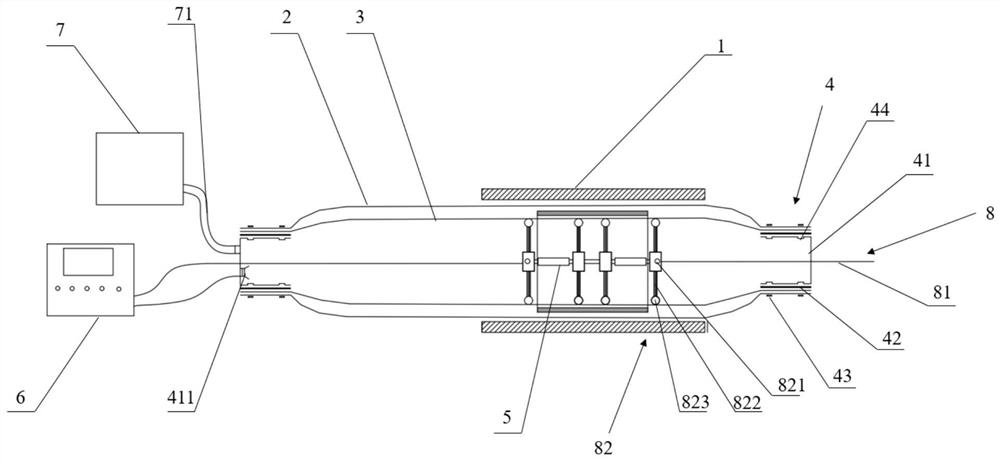

[0025] Such as figure 1 As shown, the present invention provides an ultraviolet curing device for a ring-shaped sample of a lining pipe, which includes a fixture 1, a first tube film 2, a second tube film 3, an ultraviolet lamp 5, a controller 6, an air pressure machine 7 and traction mechanism 8, the second tube film 3 is arranged in the first tube film 2, and the fixing part 1 is arranged outside the first tube film 2 for fixing the first tube film 2 and the two ends of the second tube film 3 The opening is provided with a sealing assembly 4 for sealing it, and the ultraviolet lamp 5 is arranged inside the second tube film 3; the traction mechanism 8 runs through any sealing assembly 4 and is connected with the ultraviol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com