Automatic detection lubricating device of grinding machine for furniture production

An automatic detection and lubrication device technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine tool parts, etc., can solve the problems of grinding machine temperature rise, grinding machine thermal deformation, overflow and waste, etc. Achieve the effects of improving production efficiency, prolonging service life and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

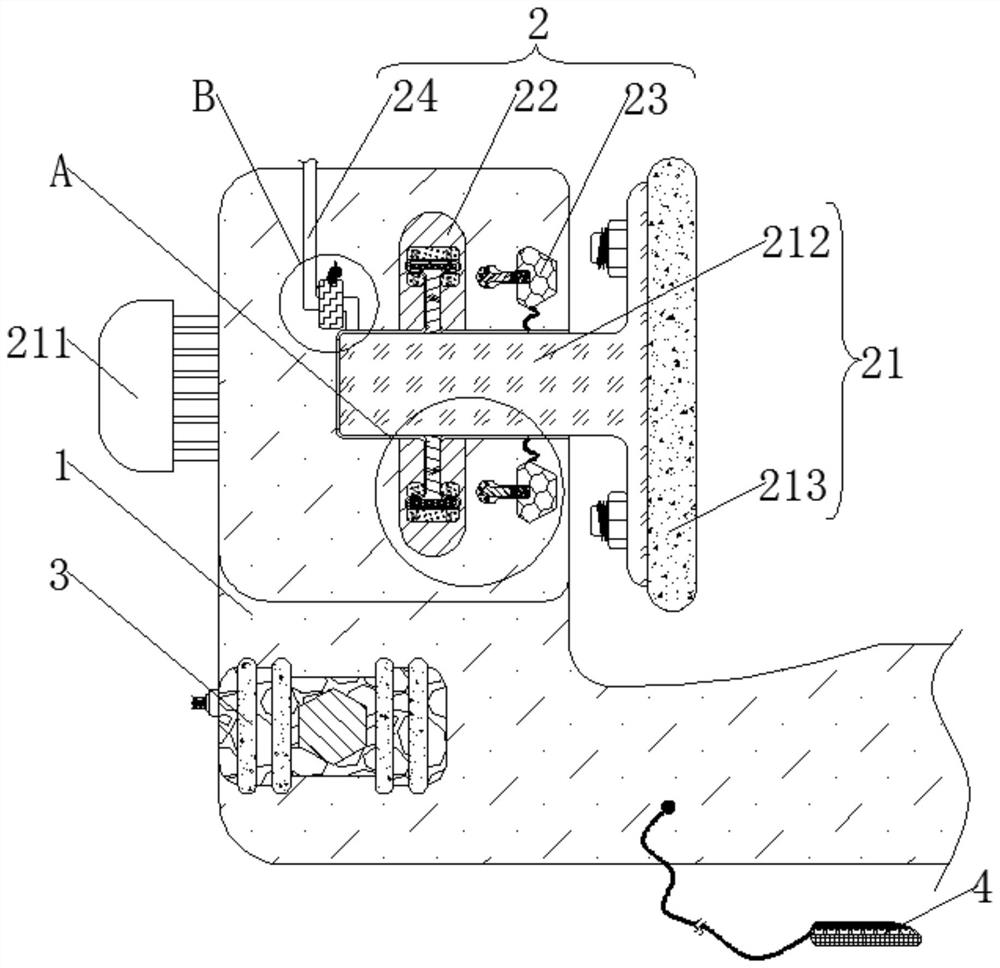

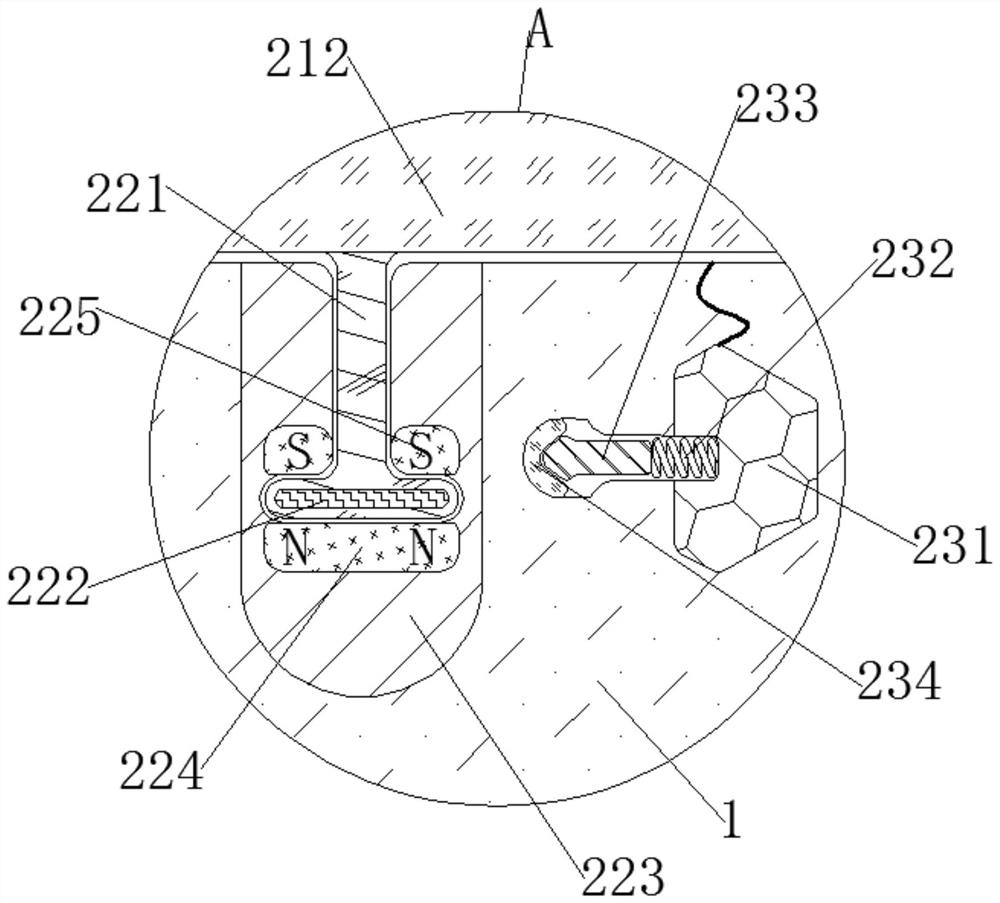

[0026] see Figure 1-2 , an automatic detection lubrication device for a grinding machine for furniture production, comprising a fixed shell 1, a detection lubrication mechanism 2 is arranged inside the fixed casing 1, the detection lubrication mechanism 2 includes a lubrication assembly 24, and the interior of the fixed casing 1 is provided with a lubrication assembly 24, The inside of the fixed shell 1 is provided with a trigger assembly 23 that controls the operation of the lubrication assembly 24. The trigger assembly 23 includes an electromagnet 231, a spring 232, an iron block 233, and a contact piece 234. The inside of the fixed shell 1 is fixedly connected with an electromagnet 231 and a spring 232. One end of the spring 232 is fixedly connected to the outside of the electromagnet 231, and the other end of the spring 232 is fixedly connected to an iron block 233. The iron block 233 is slidably connected to the inside of the fixed shell 1, and the contact piece 234 is fi...

Embodiment 2

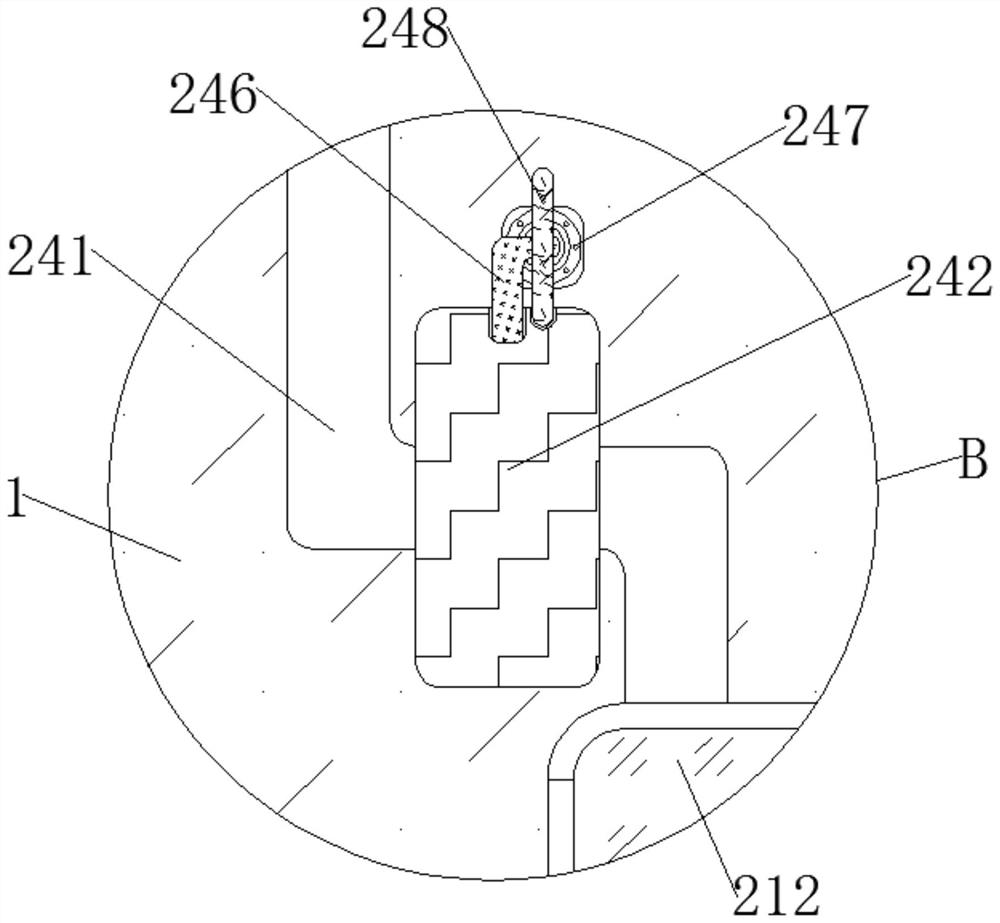

[0029] see figure 1 , 3, 4, 5, a kind of automatic detection lubrication device for furniture production grinding machine, comprises fixed shell 1, and the inside of fixed shell 1 is provided with detection lubrication mechanism 2, and detection lubrication mechanism 2 includes lubricating assembly 24, and the inside of fixed shell 1 is provided with Lubricating assembly 24, lubricating assembly 24 comprises oil pipe 241, cylindrical shell 242, chute 243, triangular block 244, rotating ring 245, linkage rod 246, electric telescopic rod 247, slide block 248, and the inside of fixed shell 1 is fixedly connected with oil pipe 241 , the cylindrical shell 242 is fixedly connected to the outside of the oil pipe 241, the oil pipe 241 corresponds to the position of the rotating shaft 212, the inside of the oil pipe 241 is provided with lubricating oil, the chute 243 is set on the inner wall of the cylindrical shell 242, and the triangular block 244 is flexibly connected to the cylindr...

Embodiment 3

[0032] see Figure 1-5 , an automatic detection lubrication device for a grinding machine for furniture production, comprising a fixed shell 1, a detection lubrication mechanism 2 is arranged inside the fixed casing 1, the detection lubrication mechanism 2 includes a lubrication assembly 24, and the interior of the fixed casing 1 is provided with a lubrication assembly 24, The lubricating assembly 24 comprises oil pipe 241, cylindrical shell 242, chute 243, triangular block 244, rotating ring 245, linkage rod 246, electric telescopic rod 247, slide block 248, and the inside of fixed shell 1 is fixedly connected with oil pipe 241, cylindrical shell 242 The oil pipe 241 is fixedly connected to the outside of the oil pipe 241, and the position of the oil pipe 241 corresponds to the rotating shaft 212. The inside of the oil pipe 241 is provided with lubricating oil. The outside of the triangular block 244 is fixedly connected with a block, the block is slidably connected to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com