Rust removal equipment capable of treating bent steel bars

A steel, bending technology, used in the field of rust removal equipment that can handle bent steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

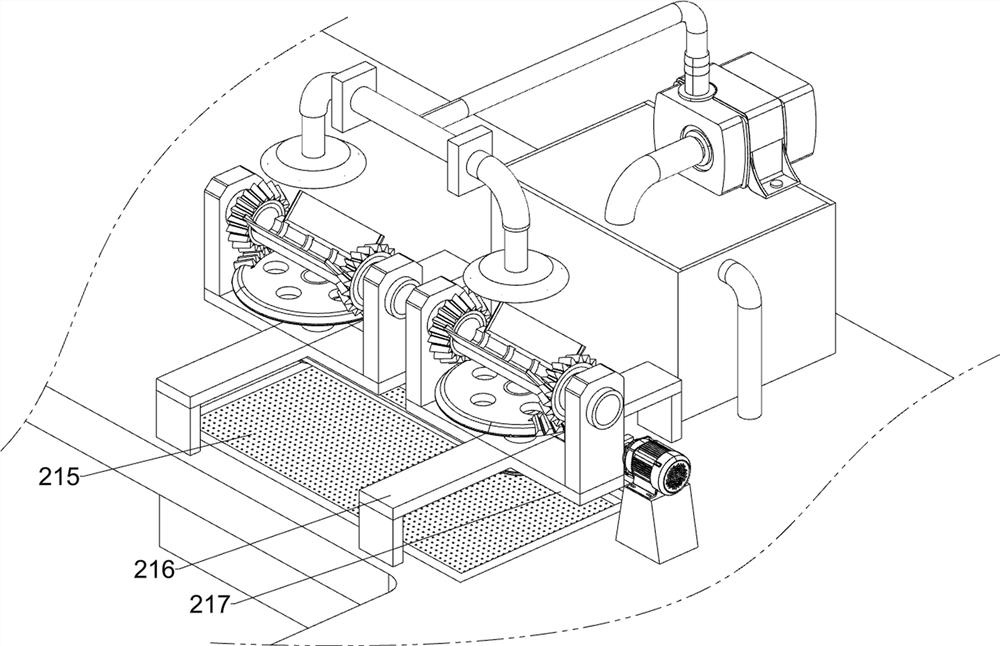

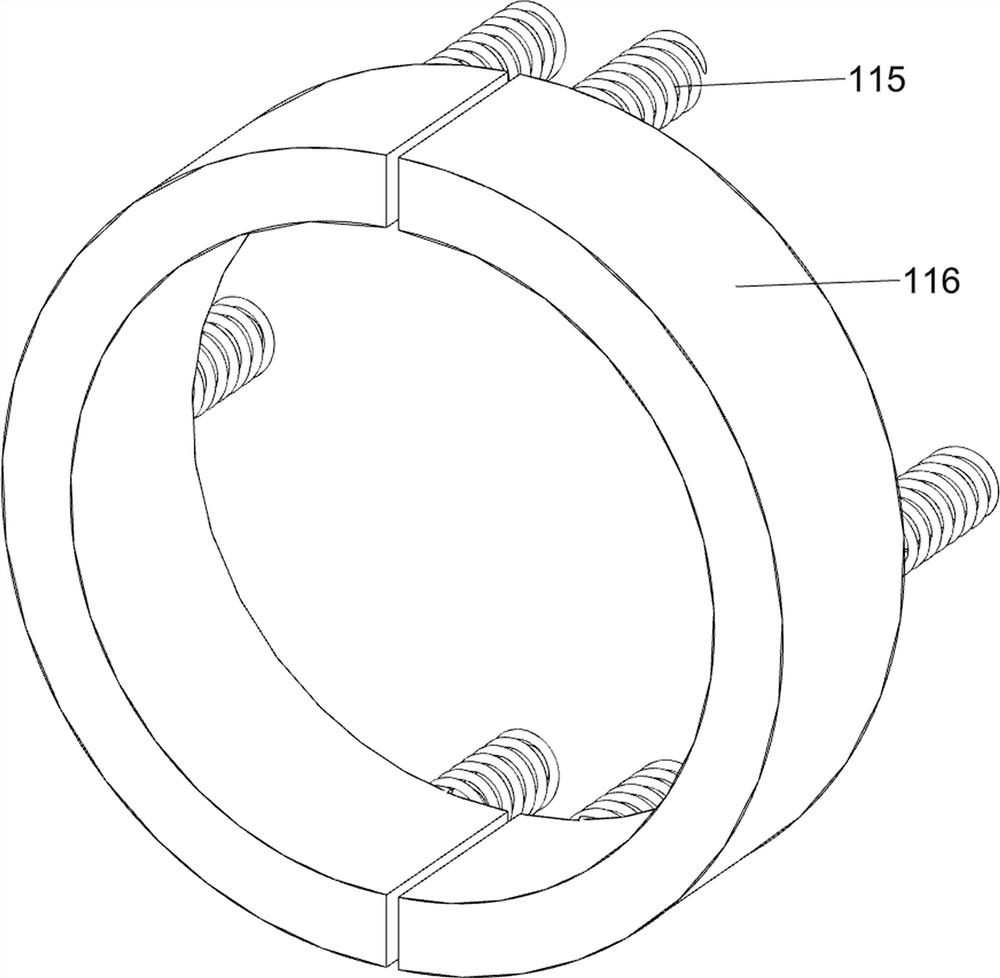

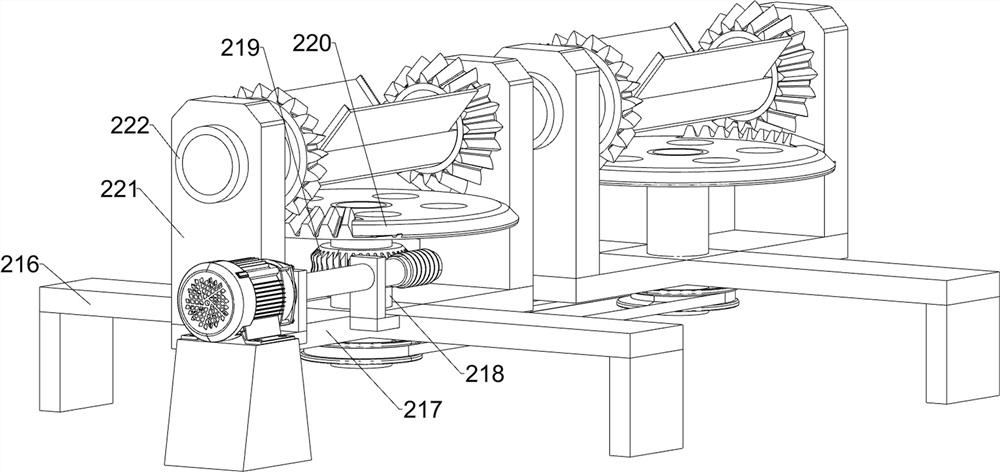

[0039] A descaling device that can handle bent steel bars such as Figure 1-15 As shown, it includes an underframe 1, casters 2, a straightening system, a first derusting system and a second derusting system; each of the four corners of the underframe 1 is connected with a caster 2; the front part of the upper side of the underframe 1 is connected with a straightening system; the upper middle part of the bottom frame 1 is connected with the first rust removal system; the upper rear part of the bottom frame 1 is connected with the second rust removal system; the first rust removal system is connected with the second rust removal system.

[0040] When using the derusting equipment that can handle bent steel bars, the operator places a coil of steel bars to be processed in the peripheral conveying equipment, and the peripheral conveying equipment is placed in front of the straightening system, and the steel bars are conveyed through the peripheral conveying equipment , during the...

Embodiment 2

[0053] On the basis of Example 1, such as figure 1 and Figure 16 As shown, a transmission system is also included; the upper side of the chassis 1 is connected with the transmission system; the transmission system is located behind the straightening system; the transmission system includes the tenth support plate 501, the first electric rotating shaft 502, the first dial 503, the The eleventh support plate 504, the guide roller 505, the twelfth support plate 506, the second electric rotating shaft 507 and the second dial 508; Located behind the second support plate 105; the upper right part and the middle part of the right side of the tenth support plate 501 are each rotatably connected with a first electric rotating shaft 502; the right sides of the two first electric rotating shafts 502 are respectively fixedly connected with a first dial 503 There are two eleventh support plates 504 fixedly connected to the middle part of the upper side of the underframe 1; the two eleven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com