Pickering emulsion for improving oxidation stability of dispersed-phase grease and preparation method of Pickering emulsion

A technology of oil oxidation and dispersed phase, which is applied in the field of food processing, can solve the problems of easy oxidation of sterols, achieve good results, save costs, and improve oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

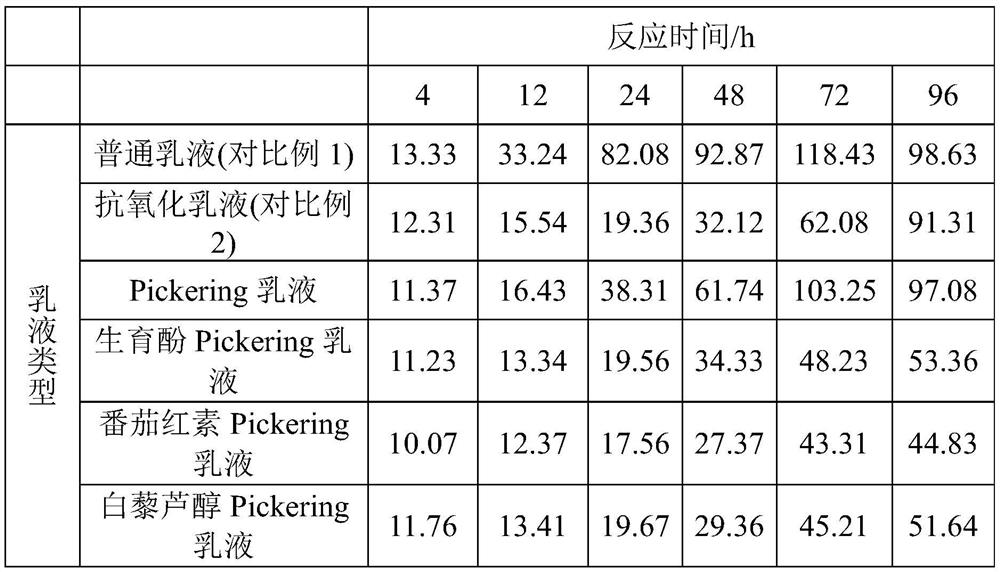

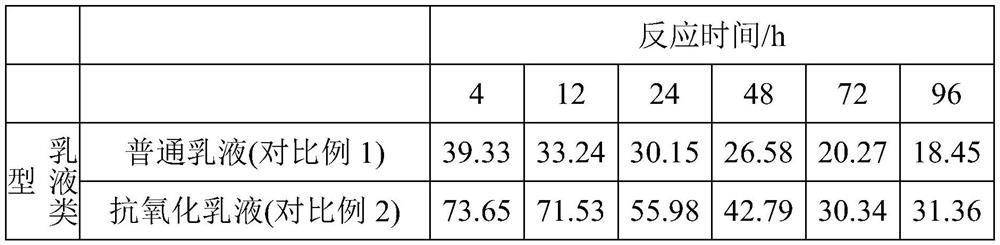

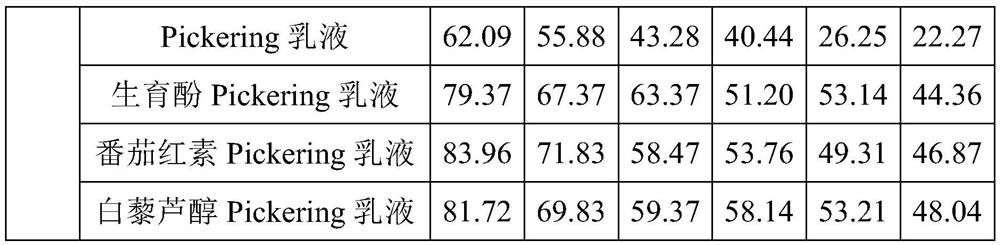

Examples

Embodiment 1

[0037] 1. Preparation of Pickering emulsion

[0038]1. Preparation of Glyceride Dispersion Phase Containing Antioxidant

[0039] Antioxidants (tocopherol, resveratrol, lycopene) were dissolved in methanol solution and added to molten trimyristin at 80°C at a concentration of 446 μmol / kg.

[0040] 2. Adjust the content of glyceride dispersed phase

[0041] In a water bath at 80°C, the above-mentioned glyceride dispersed phase was added to a PBS solution containing 1% emulsifier sodium caseinate (NaCAS). Homogenize at a speed of 11,000rpm and stir at high speed for 1min. The obtained mixed solution was homogenized, and circulated 5 times at 400 bar under the condition of 80°C. A 5% w / w dispersion of CLP was prepared. The CLP dispersion was cooled to 4°C.

[0042] 3. Preparation of oil phase containing sterols

[0043] Add the phytosterol mixture to the walnut oil, stir to make it dissolve completely, and obtain an oil phase containing 0.5% w / w phytosterol.

[0044] 4. Pre...

Embodiment 2

[0071] 1. Preparation of Pickering emulsions with different materials

[0072] 1. Preparation of Glyceride Dispersion Phase Containing Antioxidant

[0073] Dissolve resveratrol in methanol solution, and add molten lipid (one or more of rice bran wax, palm wax, stearate, palmitate, arachidate, and linolenate) at 85°C. The formula of CLP glyceride is shown in Table 3.

[0074] 2. Adjust the content of glyceride dispersed phase

[0075] In a water bath at 80° C., the above-mentioned glyceride dispersed phase was added to a PBS solution containing 1% emulsifier (whey protein and sodium caseinate). Homogenize at a speed of 11,000rpm and stir at high speed for 1min. The obtained mixed solution was homogenized, and circulated 5 times at 400 bar under the condition of 80°C. A 5% w / w dispersion of CLP was prepared. The CLP dispersion was cooled to 4°C.

[0076] 3. Preparation of oil phase containing sterols

[0077] Add the phytosterol mixture to the rapeseed oil, stir to dissol...

Embodiment 3

[0089] 1. Preparation of Pickering emulsion

[0090] 1. Preparation of Glyceride Dispersion Phase Containing Antioxidant

[0091] Resveratrol was dissolved in methanol solution, and the molten tripalmitin was added at 80°C to a concentration of 446 μmol / kg.

[0092] 2. Adjust the content of lipid dispersed phase

[0093] In a water bath at 80° C., the above-mentioned glyceride dispersed phase was added to a PBS solution containing 1% emulsifier (soy protein isolate). Rotor-stator homogeneous stirring at a speed of 11,000rpm for 11min. The resulting mixture was homogenized and ultrasonicated for 20 minutes at 20Mhz frequency and 95% power while maintaining 80°C. Afterwards, a 5% w / w CLP dispersion was prepared by performing high-pressure homogenization at 400 bar for 5 cycles. The CLP dispersion was cooled to 4°C.

[0094] 3. Preparation of oil phase containing sterols

[0095]Add phytosterols (camesterol, brassicasterol, stigmasterol, sitosterol) to rapeseed oil, stir to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com