Monitoring management method for equipment and tools in power industry

A technology of monitoring and management in the power industry, applied in the field of material supervision, can solve the problems of high manpower and material resources consumption, and the inability to quickly grasp the status of tools in and out of storage, etc., to achieve the effects of low consumption, convenient replacement, and extended battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

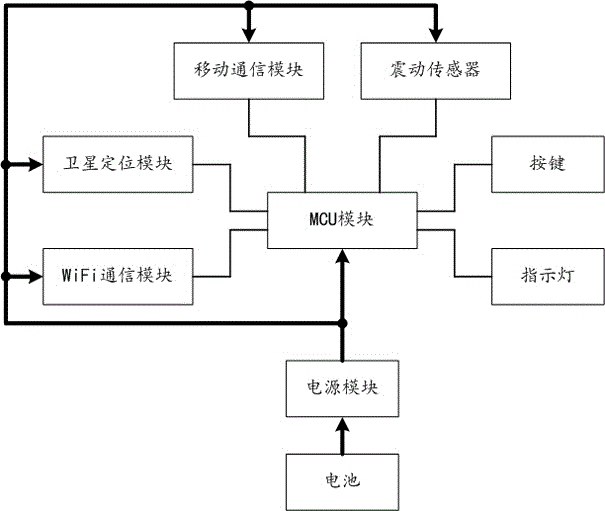

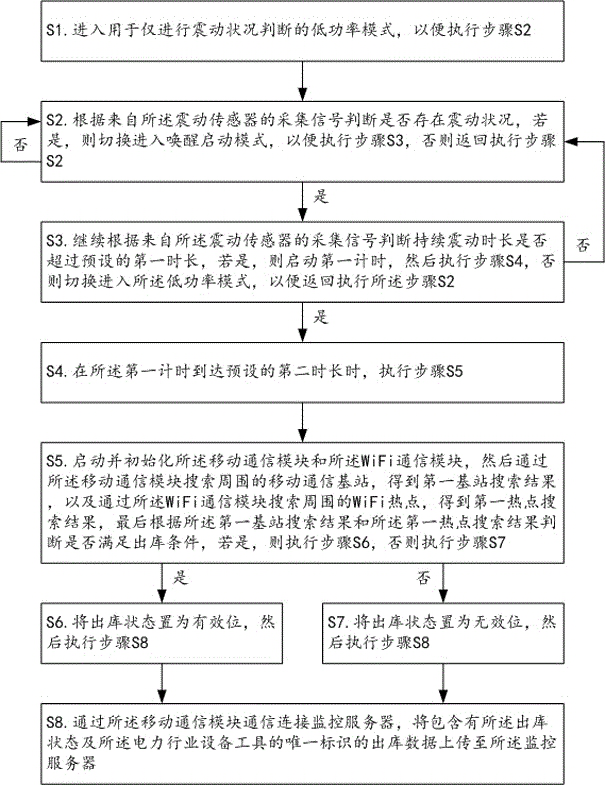

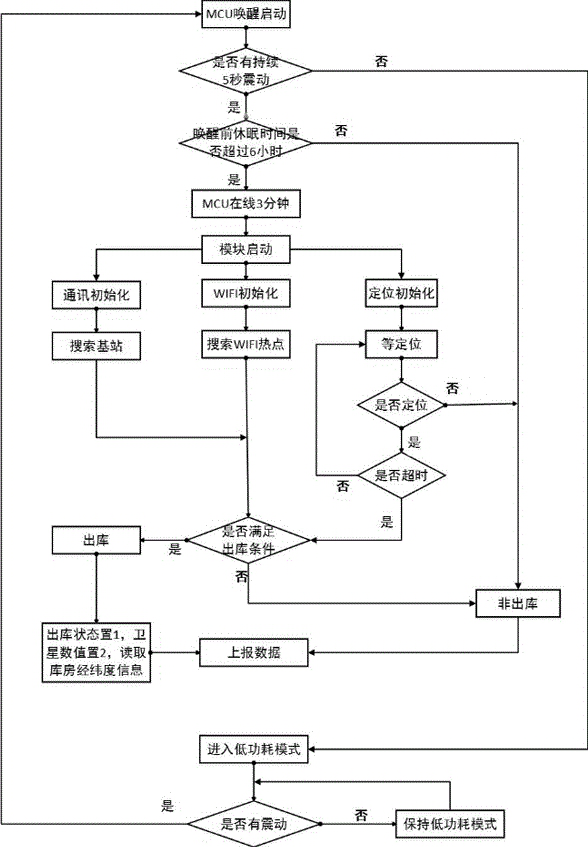

[0062] Such as Figure 1-8 As shown, the monitoring and management method of the power industry equipment tool provided by this embodiment is applicable to the terminal equipment bound with the power industry equipment tool, wherein the terminal equipment includes but is not limited to a Microcontroller Unit MCU (Microcontroller Unit ) module and a shock sensor, a wireless fidelity WiFi communication module, a mobile communication module, etc. that are respectively connected in communication with the MCU module. Such as figure 1 As shown, in the specific structure of the terminal device, the shock sensor is an existing sensor used to receive the external vibration mechanical quantity and convert it into a proportional electric quantity (that is, the collected induction signal). Sensor, can preferably adopt triaxial shock sensor; Described WiFi communication module is a kind of existing communication module based on WiFi wireless communication technology; Described mobile comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com