Light fire hydrant with locking function and high stability and use method

A fire hydrant and stability technology, which is applied in the field of light fire hydrants, can solve the problems of valve stem and disc damage, valve stem slipping out, poor stability, etc., to protect the valve body, improve service life, and reduce wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

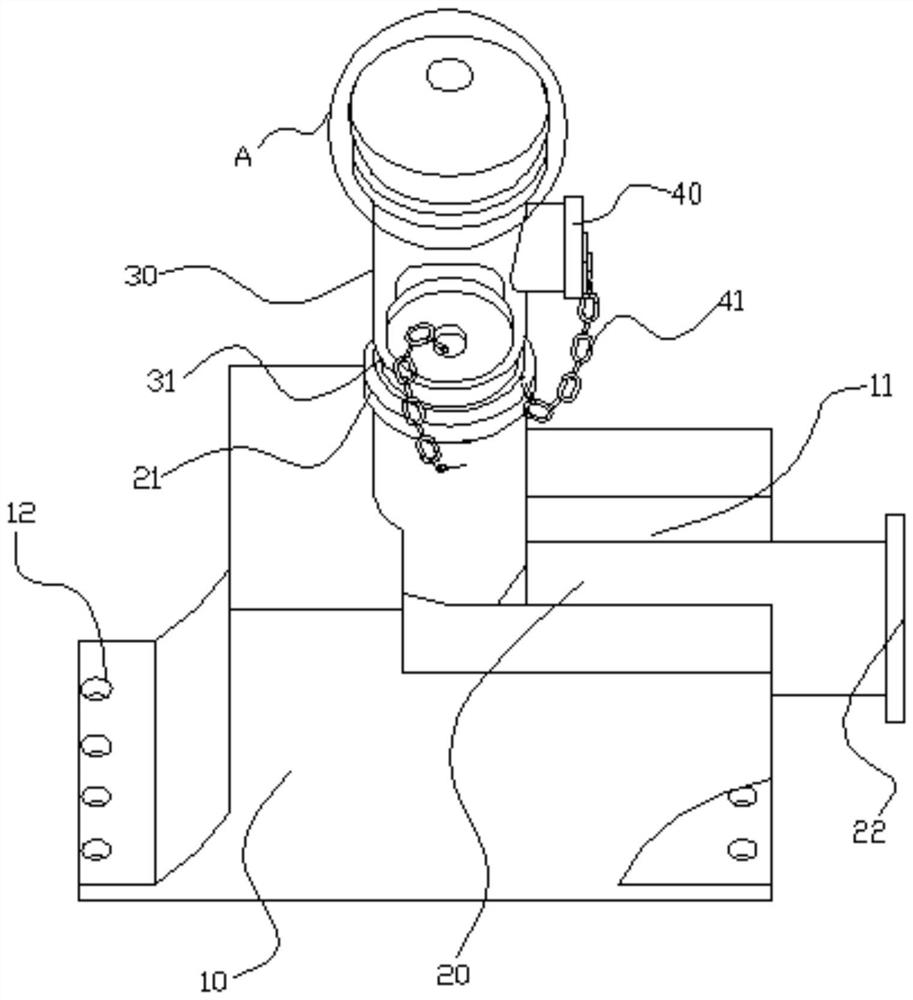

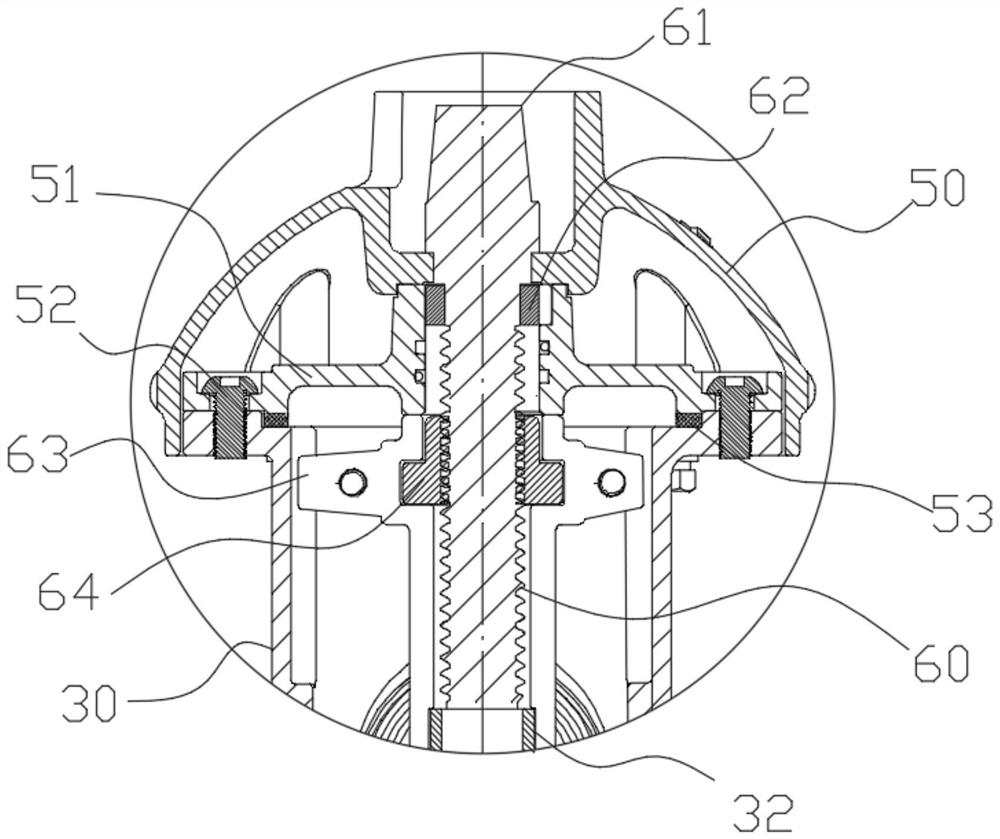

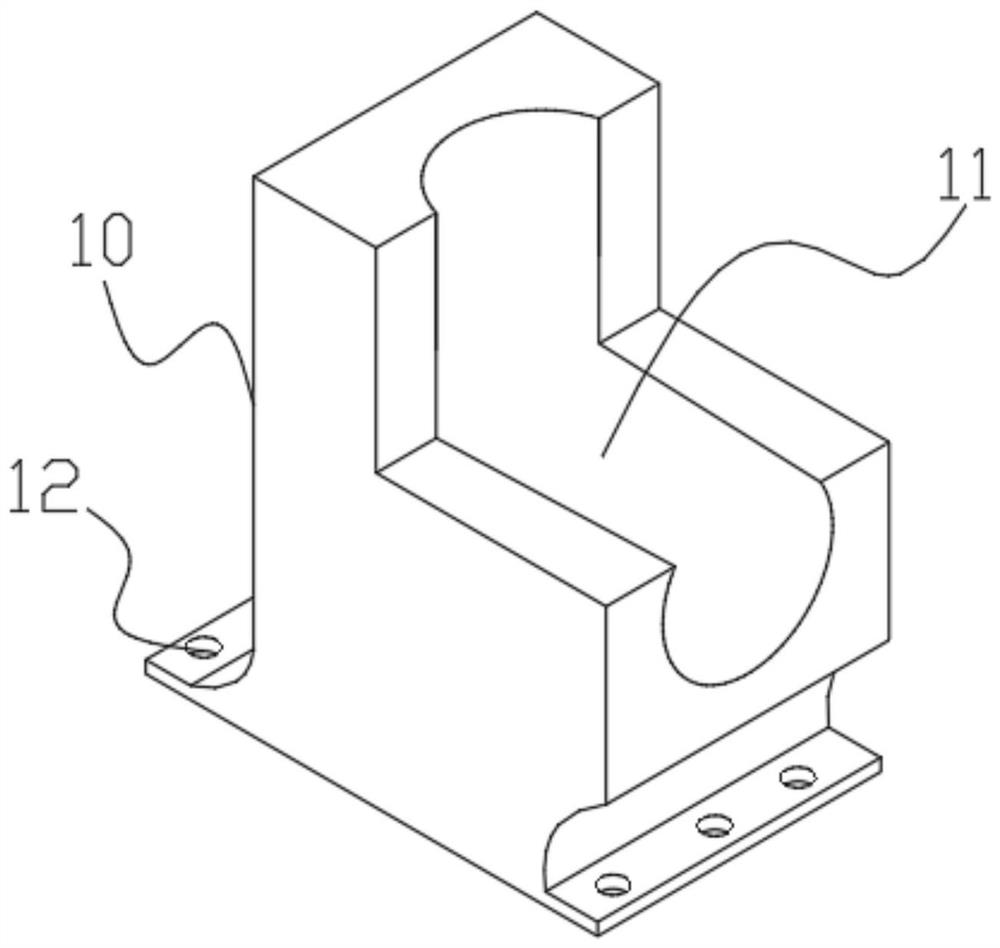

[0026] refer to figure 1 and Figure 4 As shown, a light fire hydrant with locking function and high stability includes an installation base 10, a water inlet pipe 20 and a bolt body 30, and a connecting pipe 32 is arranged inside the bolt body 30, and the lower end of the connecting pipe 32 A rubberized valve disc 33 is connected, and the rubberized valve disc 33 is located in the limiting chamber 31 of the plug body 30. The limiting chamber 31 cooperates with the rubberized valve disc 33 to form a closed chamber, which cuts off the upward flow of the water body. Circulation, the lower part of the limit chamber 31 is provided with an expansion chamber 21, when the connecting pipe 32 drives the rubber-covered valve disc 33 to move down into the expansion chamber 21, the plug body 30 is opened, and the water body begins to circulate upward; the water inlet pipe 20 is curved Arc-shaped structure, the water inlet end of the water inlet pipe 20 is provided with a flange 22, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com