Biochemical test paper card assembling equipment

A technology for assembly equipment and test paper cards, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, achieve the effect of improving yield rate, improving production efficiency, and ensuring assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

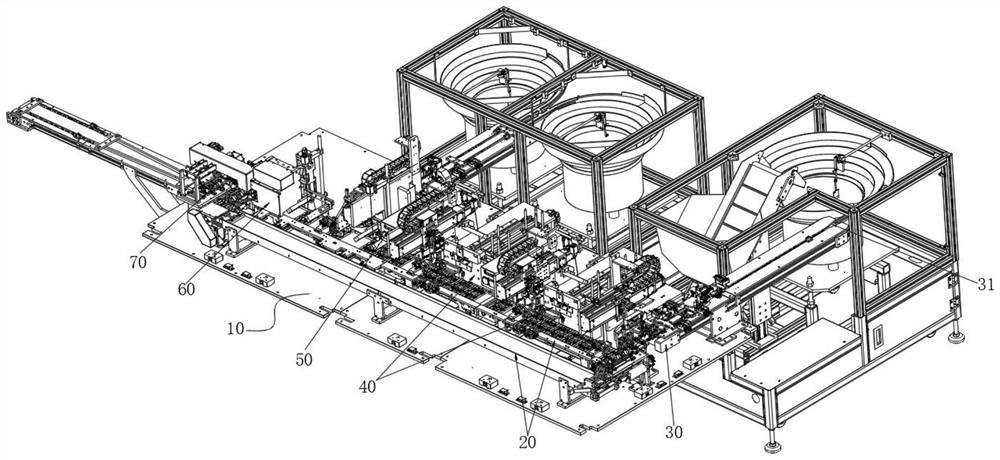

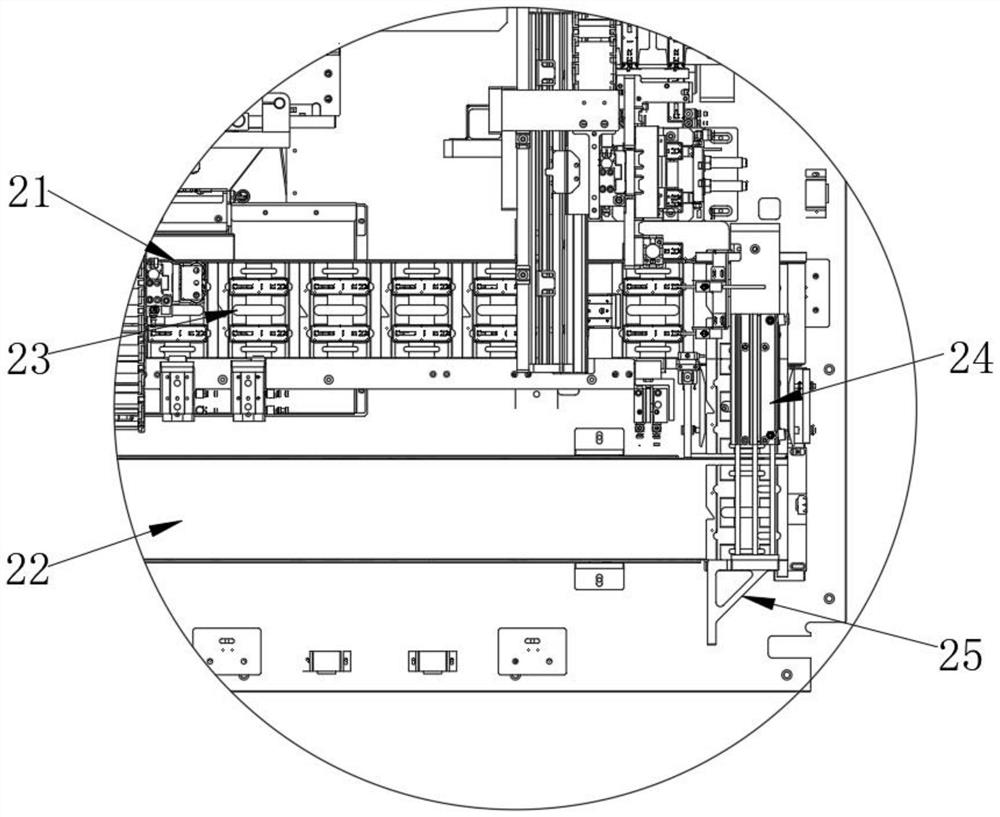

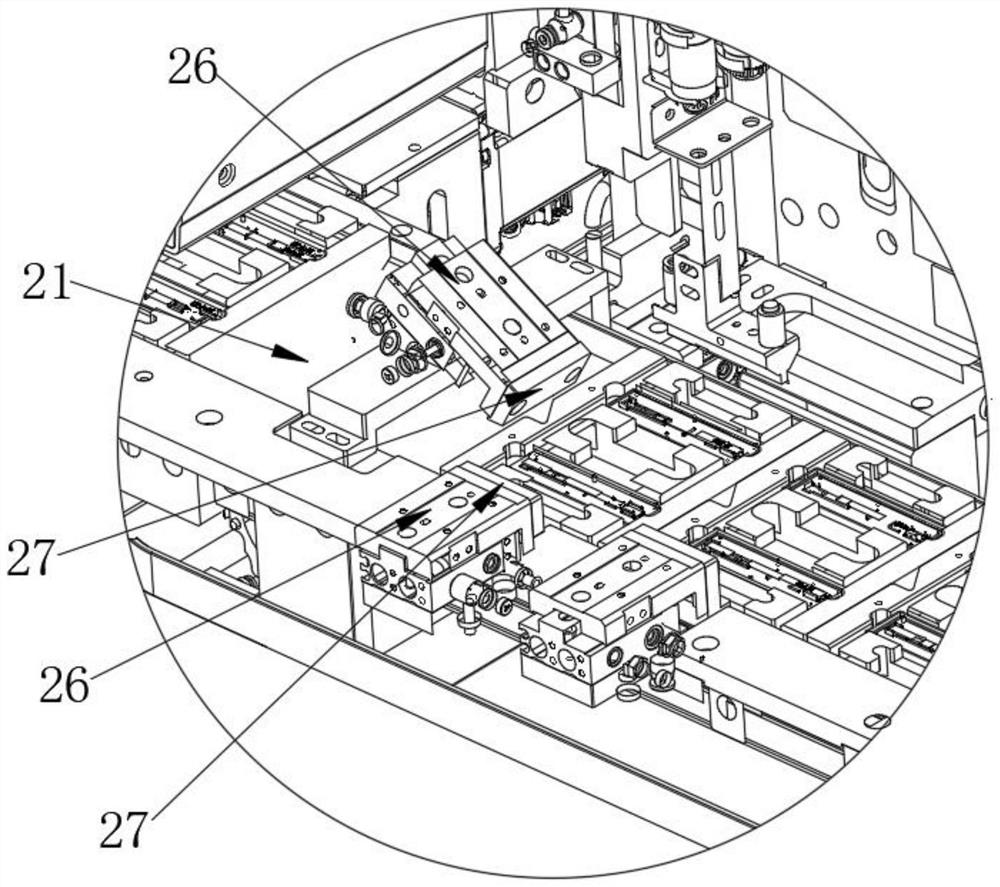

[0072] Specifically, such as figure 1 As shown, the embodiment of the present application provides a biochemical test strip card assembly equipment, including a machine base 10, a material conveying mechanism 20, a bottom card loading station 30, a test strip loading station 40, and a face card loading station 50 , card pressing station 60 and blanking detection station 70, wherein, the material conveying mechanism 20 is arranged on the machine base, and the material conveying mechanism 20 is used to convey bottom cards, face cards, and test strips; The base card feeding station 30 is arranged at one end of the material conveying mechanism 20, and the bottom card feeding station 30 is used to transport the bottom card to the material conveying mechanism 20; Position 40 is arranged on the downstream of the bottom card feeding station 30, and the test strip feeding station 40 is used to transport the test strip to the bottom card on the material conveying mechanism 20; The mate...

Embodiment 2

[0094] The difference between this embodiment and Embodiment 1 is that the feeding methods of the base card and the surface card are different;

[0095] Specifically, such as Figure 11 As shown, the bottom card feeding station includes at least two bottom card feeding mechanisms 301, at least two bottom card conveyor belts 302, and a bottom card is arranged between the bottom card feeding mechanism and the bottom card conveyor belts. Card transfer mechanism 303 and two bottom card handling mechanisms 305; the bottom card feeding mechanism includes a material box 3011 and a feeding conveyor belt 3012 arranged in the material box, wherein the bottom card conveyor belt 3012 is provided with several steps platform; the feeding conveyor belt 3012 rotates, and the stepped platform can prevent the bottom card from sliding on the feeding conveyor belt 3012.

[0096] The bottom card transfer mechanism 303 includes a multi-joint robot 3031 and a material distribution conveyor belt 303...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com