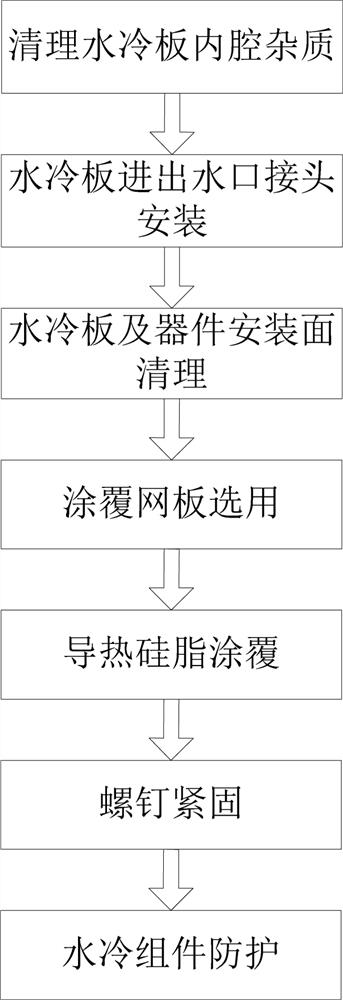

Installation process of water cooling assembly

An installation process and component technology, applied in the direction of electrical components, manufacturing tools, electrical components, etc., can solve the problems of power system operation failure, water seepage of pipe joints, uneven heat dissipation of power modules, etc., and achieve the effect of improving high reliability and solving water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

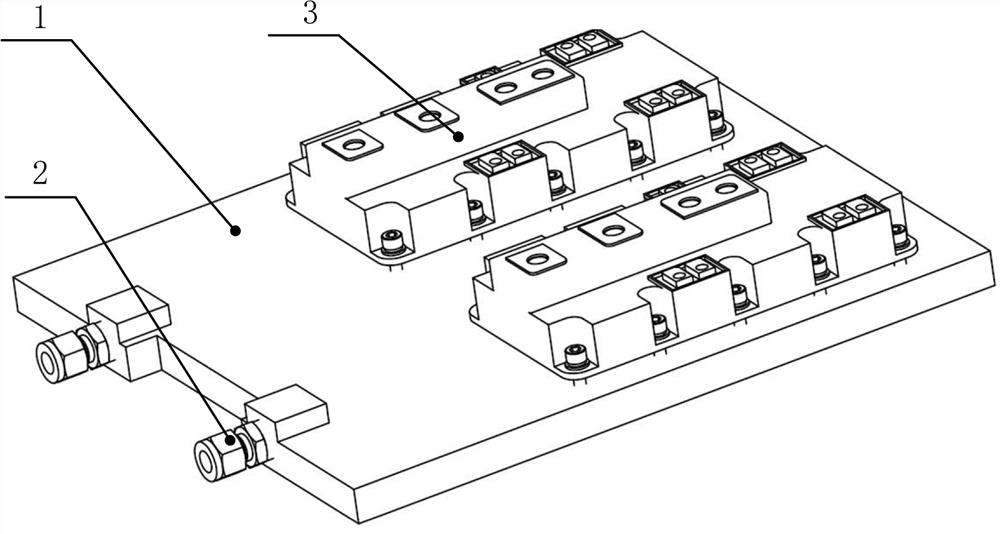

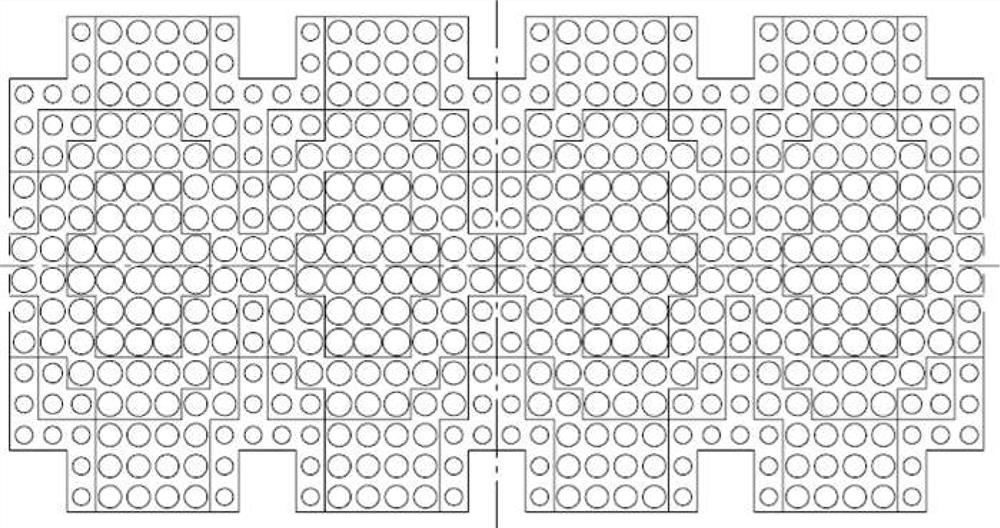

[0021] Before describing the embodiments of the present invention in detail, the application environment of the present invention will be described first. The technology of the present invention is mainly applied to the installation process of high-power water-cooled components. Experience shows that if the high-power water-cooling components cannot guarantee the reliability of the water-cooling connection, the correct installation of the power module 3 will lead to water leakage and high temperature phenomena during the operation of the water-cooling components, which will affect the product performance and life. In severe cases, it will cause a short circuit of the circuit This causes the entire circuit to fail.

[0022] like figure 1 As shown, the embodiment of the present invention discloses a water-cooling assembly installation process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com