Double-spring direct-acting overload valve

A direct-acting, double-spring technology, applied in the field of hydraulic relief valves, can solve the problems of small pressure relief cross-sectional area, slow pressure relief speed, and limited maximum pressure relief speed, and achieve convenient installation and use, high pressure relief speed Fast, increase the cross-sectional area of the release pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

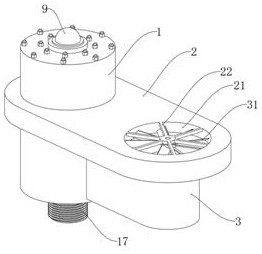

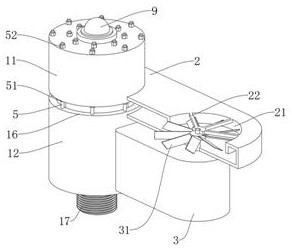

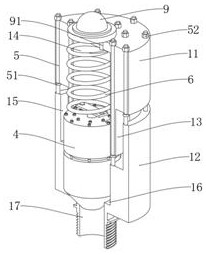

[0019] refer to Figure 1-4 , double-spring direct-acting overload valve, including valve body 1, the sealing sleeve on the outer wall of valve body 1 is provided with flow collecting box 2, and the bottom wall of flow collecting box 2 is installed with power generation and energy storage unit 3, and valve body 1 includes The upper spool 11 and the lower spool 12 have the same diameter, the lower end of the upper spool 11 is centered with an outer protrusion 13, and the bottom wall of the outer protrusion 13 of the upper spool 11 is provided with an upper valve extending into the upper spool 11. Chute 14, the top of the lower spool 12 is provided with an outer overflow groove 15, the groove bottom of the outer overflow groove 15 is provided with a lower valve chute 16, the outer protrusion 13 is inserted in the outer overflow groove 15, and the upper valve chute 14 Slidingly installed with the lower valve chute 16, the valve core 4 is installed. The upper end of the valve core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com