Steel smelting device

A technology of iron and steel smelting and rotating devices, which is applied in metal processing, waste gas treatment, climate sustainability, etc. It can solve the problems of operators and environmental impact, high emission of harmful substances, and large heat loss of blast furnace, etc., to reduce smelting time , reduce pollution and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

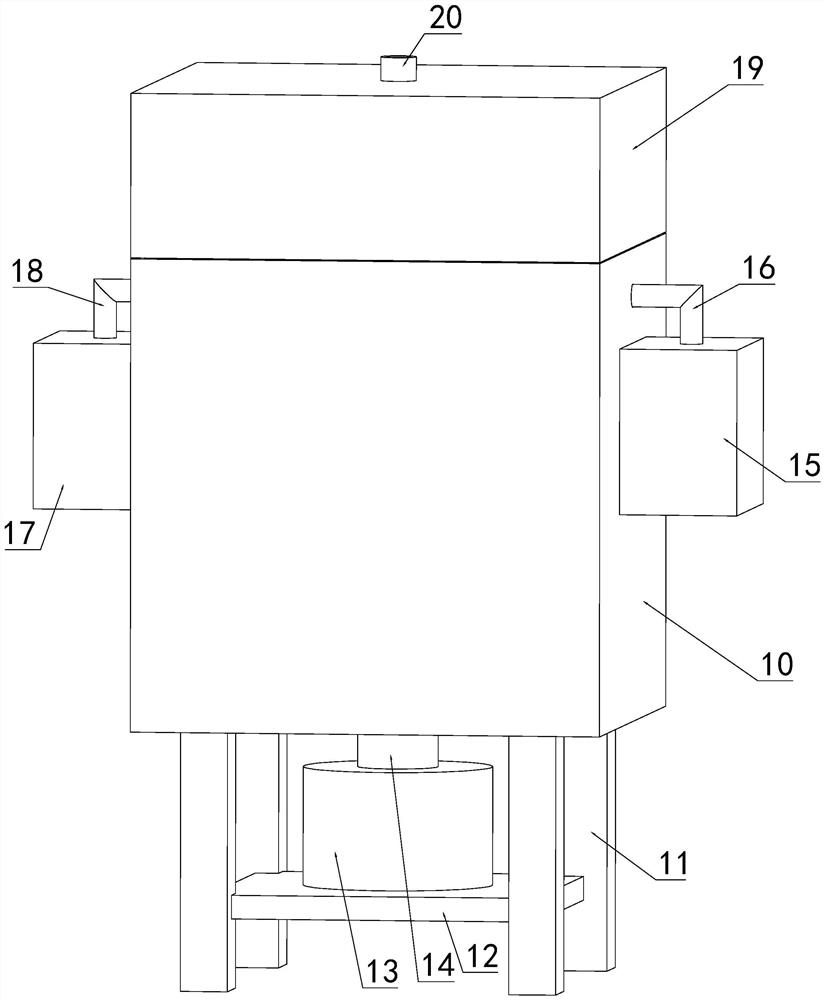

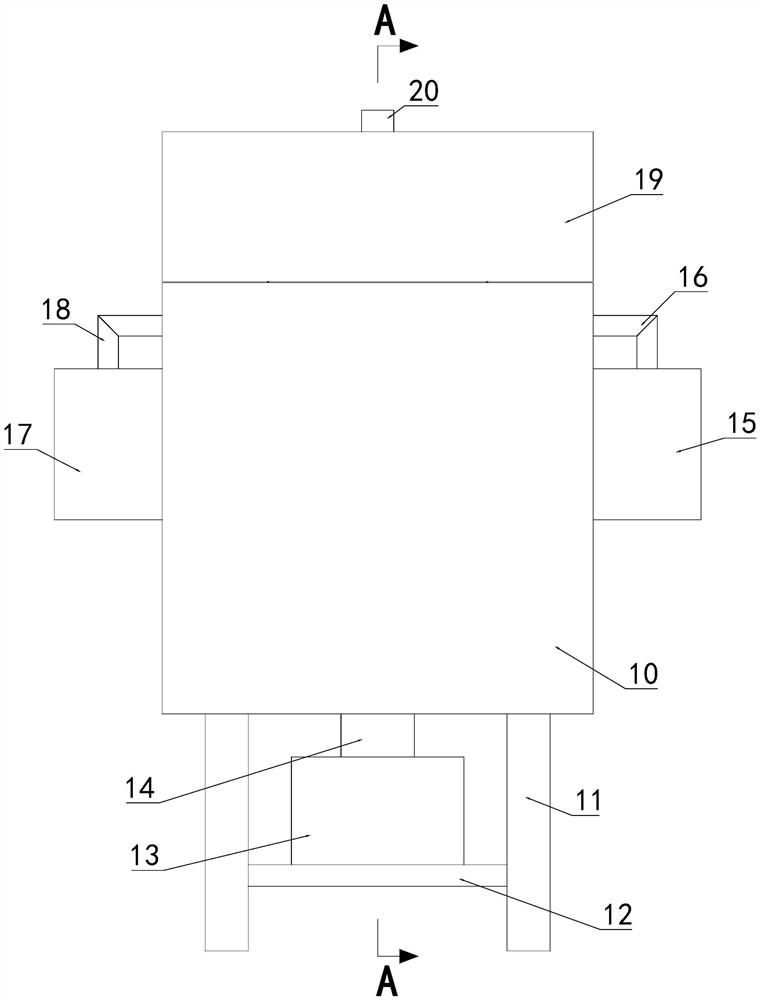

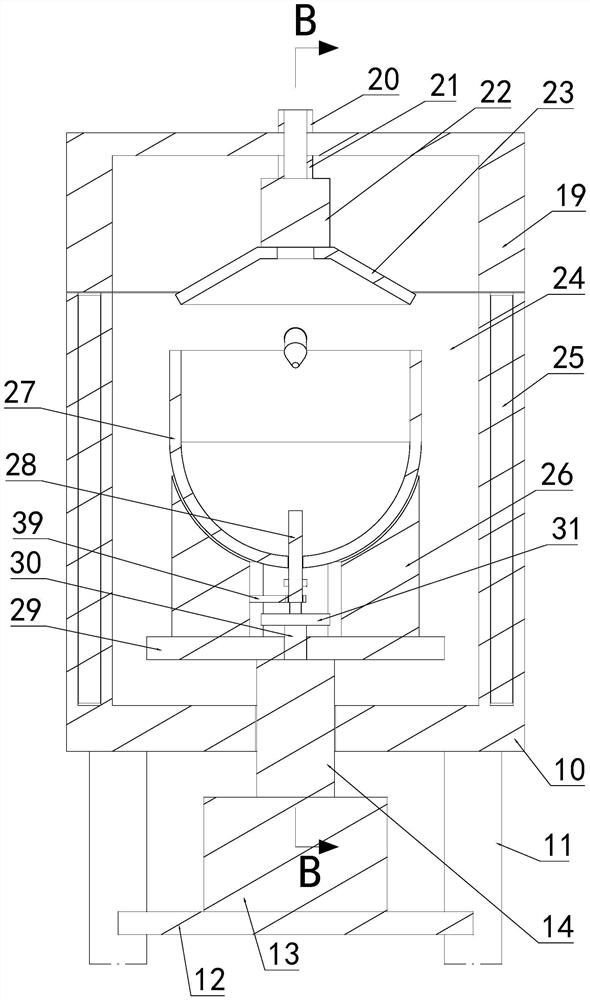

[0028] Such as figure 1 As shown, a steel smelting device includes a casing 10, four support columns 11 are fixedly arranged on the lower side of the casing 10, an upper cover 19 is slidably arranged on the upper side of the casing 10, and an exhaust gas is fixedly arranged on the upper side of the upper cover 19. hole 20, the right side of the casing 10 is fixed with a gas box 15, the upper side of the gas box 15 is fixed with a gas output pipe 16, the left side of the casing 10 is fixed with an oxygen box 17, and the upper side of the oxygen box 17 is fixed with an oxygen output Tube 18, the housing 10 is provided with a heating chamber 24, and the support column 11 is provided with a rotating device, which is used to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com