A kind of ultra-high performance concrete and preparation method thereof

An ultra-high-performance concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of large shrinkage, mismatch between strength and shrinkage, etc., to slow down the decline, make up for adverse effects, stress-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

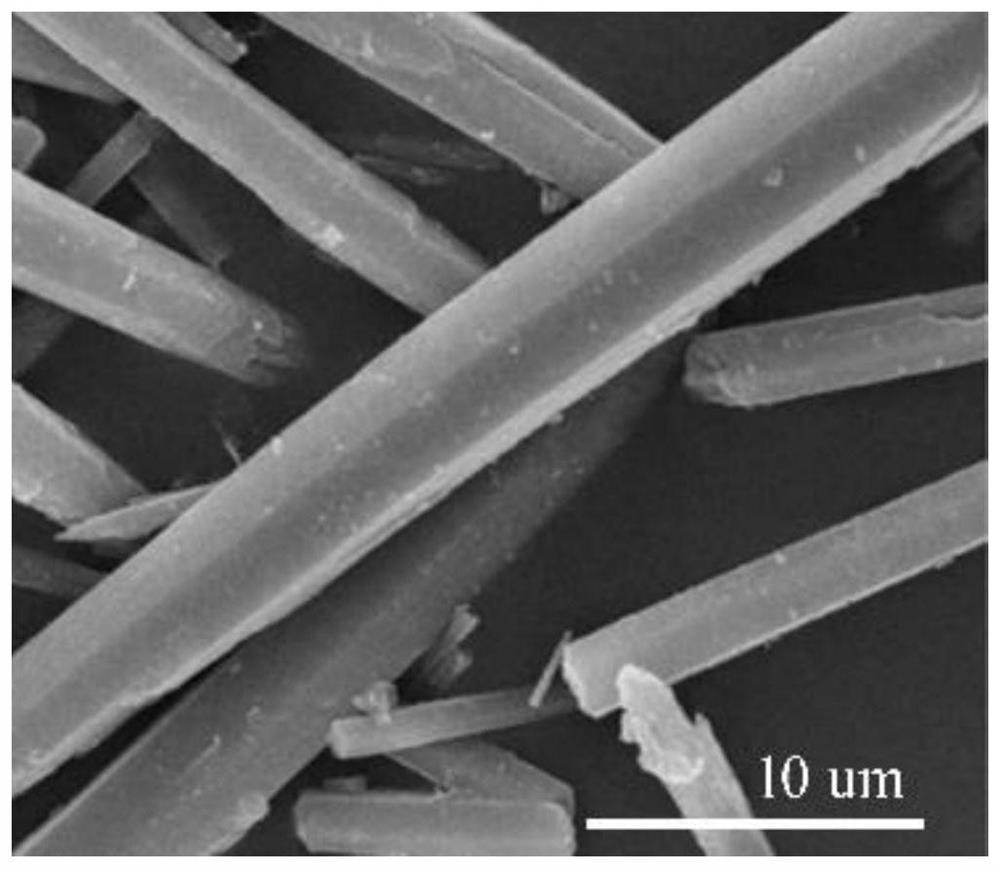

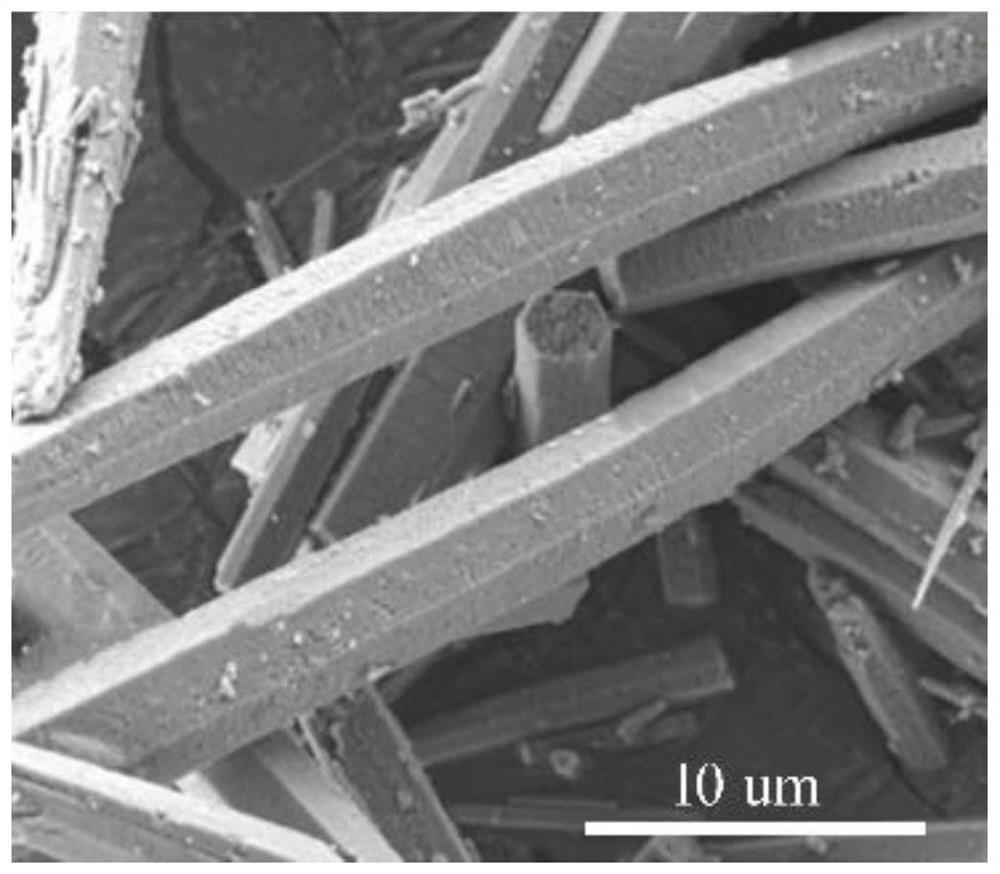

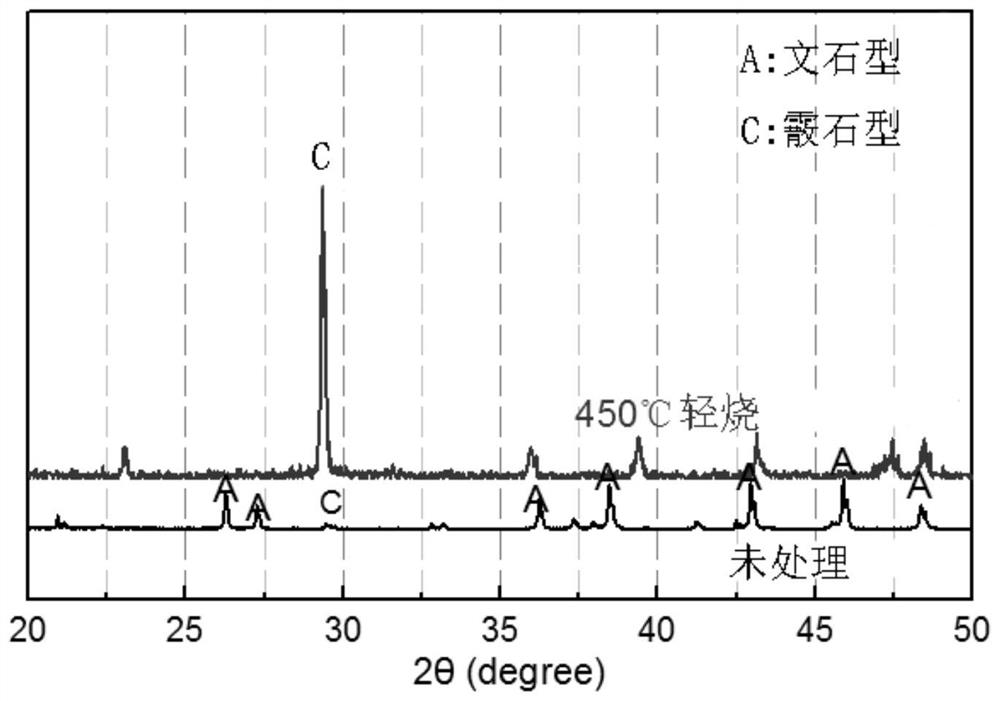

[0063] An ultra-high-performance concrete, raw materials: cement, silica ash, mineral powder, mechanism sand, gravel, steel fiber, water reducing agent, water, calcium sulfate-calcium sulfate composite expansion, bisexual ion polymer, 2 2, 2 -Methyl-2-propane, porous silicon micro powder, high water absorption resin, inorganic gel coagulant, light-yaki carbonate? According to the cooperation ratio in Table 1, there are three groups of implementation. It should be noted that the cement slurry solution of high water absorption resin in the embodiment is 30 times the water absorption multiples of the cement slurry, and the actual water glue ratio of the embodiments of each group is 0.17.

[0064] Table 1 Raw material ratio of Example 1 ~ 3 (KG / M 3 Cure

[0065]

[0066]

[0067]During the preparation process, the coordination ratio is accurate to be accurately selected by the coordination ratio. The specific preparation process is as follows: First of all, 1 / 5 of water, bisexual ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com