Ammonia mixing test device for automobile exhaust system

A technology of automobile exhaust system and test device, which is applied in the direction of measuring device, vehicle test, machine/structural component test, etc. It can solve the problems of destroying internal flow field, destroying product structure, low efficiency, etc., and achieves good measurement effect , Improve measurement efficiency and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

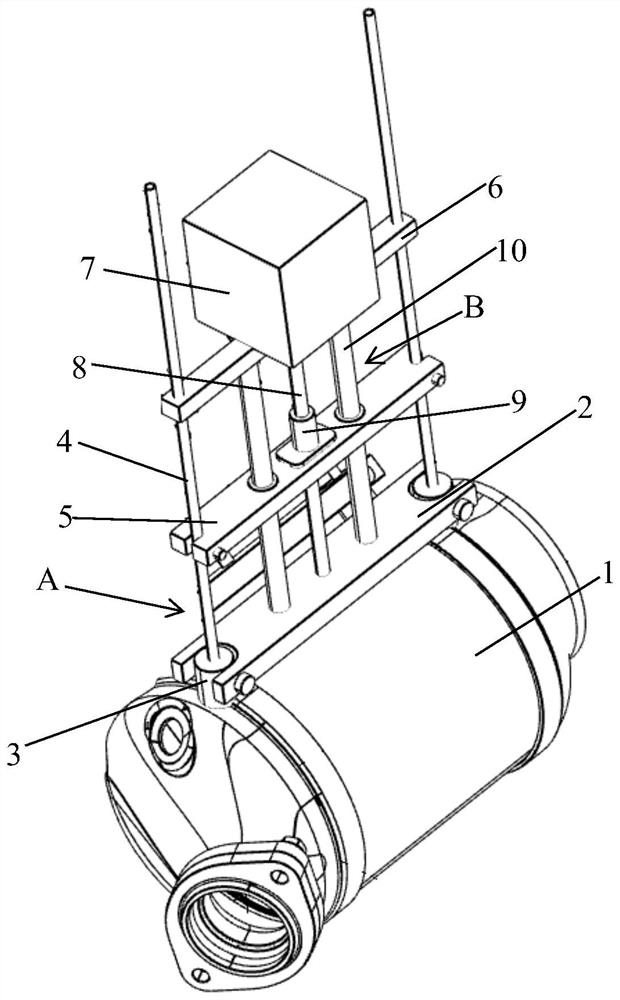

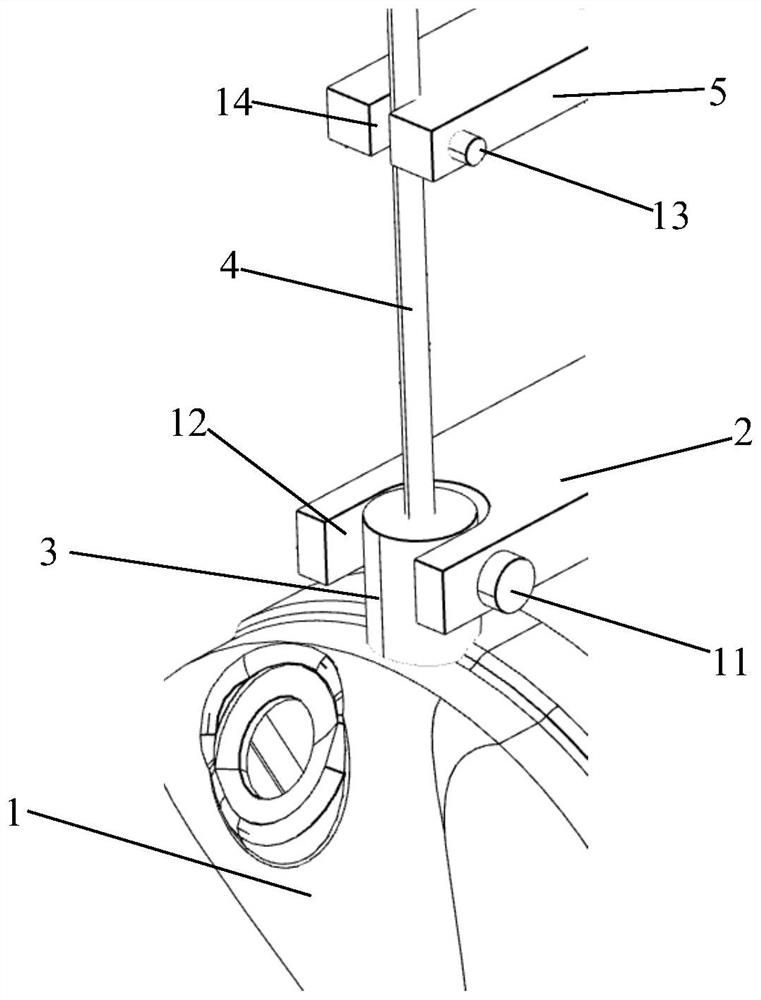

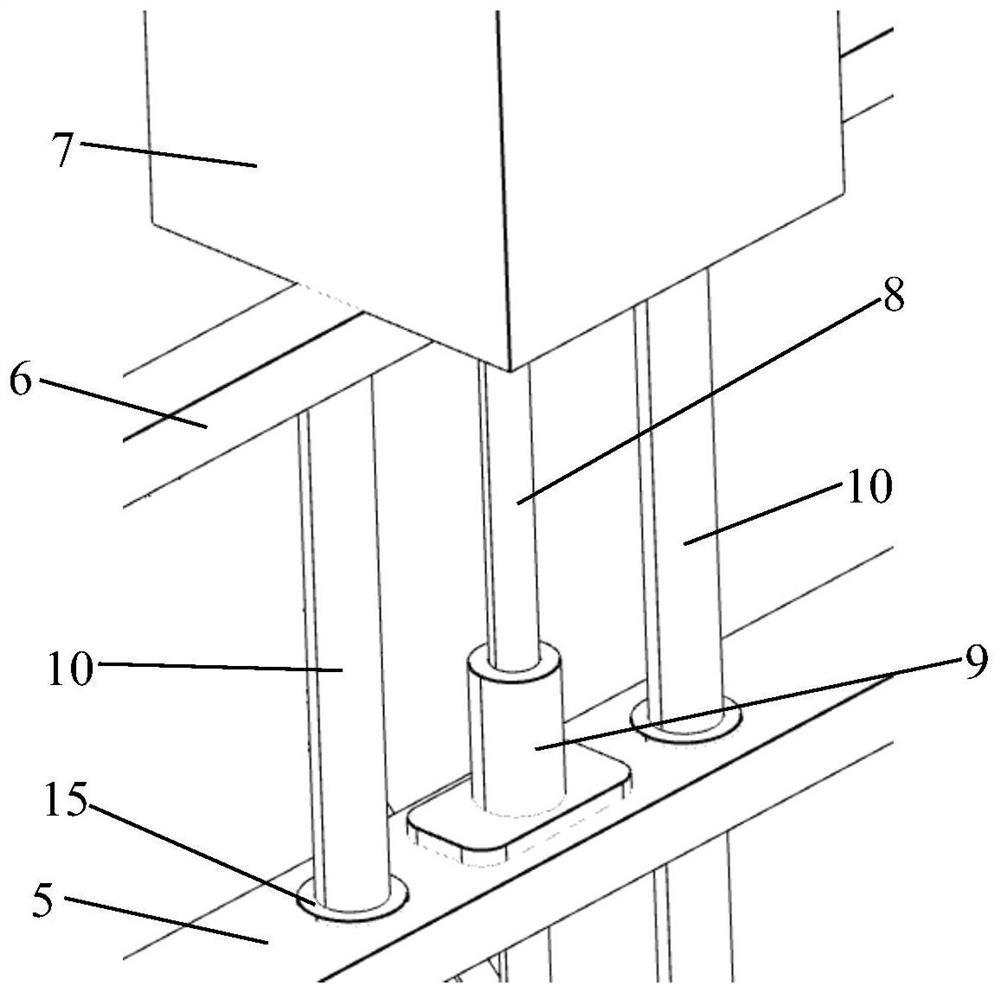

[0045] Such as Figure 1-3 As shown, this embodiment discloses an ammonia mixing test device for an automobile exhaust system. The device to be tested is a catalytic converter 1. The catalytic converter 1 has an air inlet and an exhaust port, and includes: a flexible base 2, an outer surface of the catalytic converter 1 There is a group of air-taking parts 3 on the surface, and there are two air-taking parts 3, which are arranged close to the air inlet and exhaust port of the catalytic converter 1 respectively; the air-taking parts 3 are provided with gas-taking channels up and down, and the gas-taking channels extend downwards Until it communicates with the inner cavity of the catalytic converter 1; the two ends of the flexible base 2 are respectively fixed and detachable connected with the two air-taking parts 3; One-to-one correspondence of channels; synchronous connecting rod 5, which is located above the flexible base 2, and its two ends are respectively fixedly connected...

Embodiment 2

[0054] Such as Figure 4 As shown, this embodiment adopts two sets of air extraction equipment. Compared with Embodiment 1, the air inlet and the air outlet can be simultaneously taken from two positions at the same time, which improves the efficiency and realizes an exhaust operation at the same time. The difference The air inlet and air outlet under the position take air at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com