Box-type low-temperature instant freezing equipment and working method thereof

A low-temperature, box-type technology, used in lighting and heating equipment, household refrigeration devices, defrosting, etc., can solve problems such as affecting food quality and failing to quickly cool food, and achieve the effect of improving freezing efficiency and freezing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

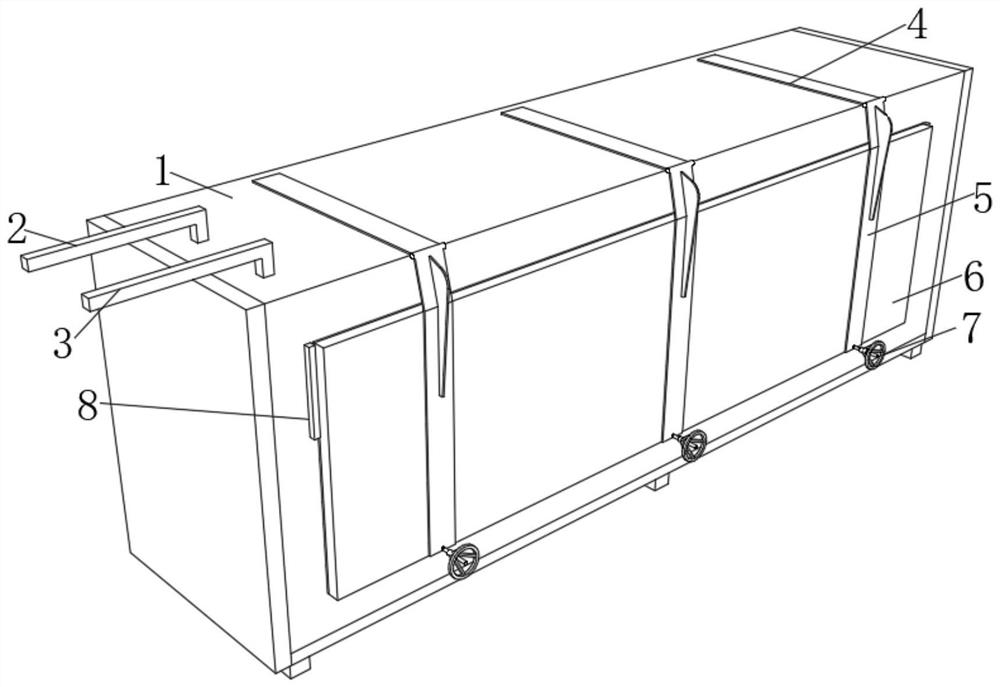

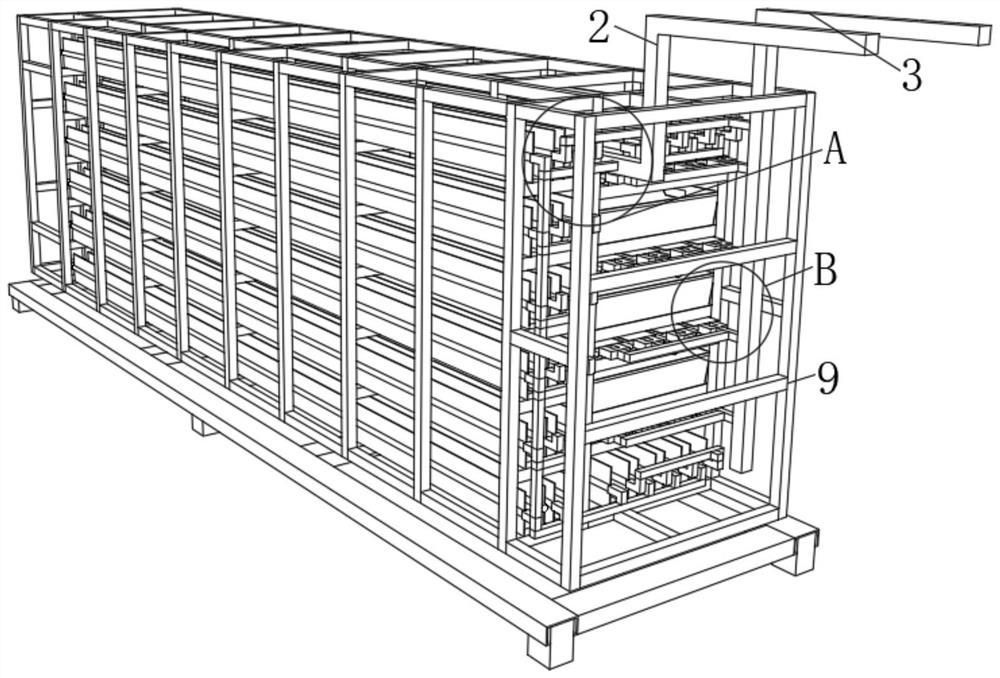

[0041] like Figure 1-Figure 6 As shown, a box-type low-temperature instant freezing equipment includes a box body 1, a liquid inlet pipe 2 is installed on the top of the box body 1, and a liquid outlet pipe 3 is installed on the top of the box body 1;

[0042] The top of the box body 1 is connected with a connecting plate 4, and one end of the connecting plate 4 is hingedly connected with a mounting plate 5, one side of the mounting plate 5 is connected with a side door 6, the surface of the side door 6 is equipped with a screw disk 7, and one part of the box body 1 A hydraulic rod 8 is installed on the side;

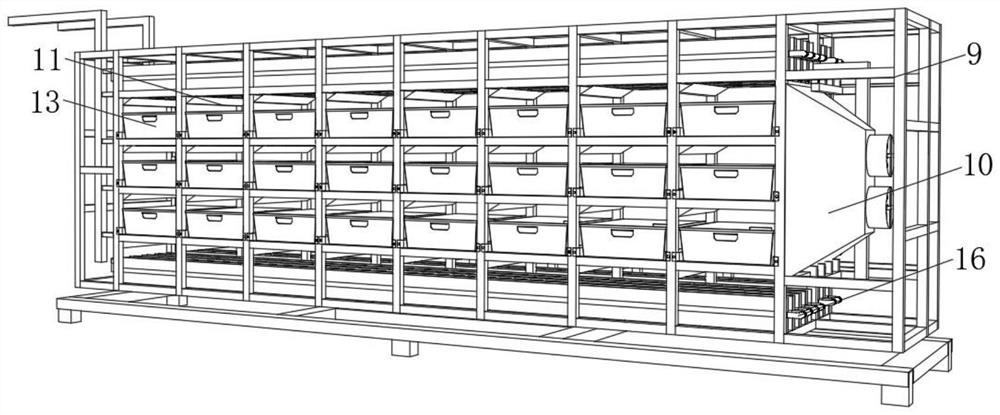

[0043] The inside of the box body 1 is equipped with a mounting frame 9, and a fan 10 is installed on one side of the mounting frame 9, a wind deflector 11 is installed on the surface of the mounting frame 9, and a placement plate 12 is installed inside the mounting frame 9, and the placement plate 12 A cargo box 13 is placed on the top of the top, and a cooling tube ...

Embodiment 2

[0058] This equipment is designed as a box-type low-temperature freezing box with a large side door, which is characterized by convenient loading of goods.

[0059] This equipment uses the brine to circulate in the refrigeration system in the box body 1 as the cooling source in the box. The feature is that a sufficient amount of brine can be pre-cooled, so the equipment reaches the pre-cooling temperature instantly when it is turned on, and the temperature is lowered. Extremely fast.

[0060] The design of this equipment is equipped with a differential pressure cold air circulation system to speed up the cooling process.

[0061] The bottom of the cargo placement plate 12 of this equipment is a metal cooling tube plate 14 and the bottom of the cargo placement plate 12 is a contact direct cooling, and the thermal conductivity of metal is hundreds of times that of water and air.

[0062] This process is added, a layer of film is covered on the top of the goods in the pallet, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com