Underground engineering surrounding rock-stress double-target mutual feedback joint regulation and control method

An underground engineering and joint control technology, which is applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problem that the self-bearing capacity of deep surrounding rocks cannot be fully mobilized, and the stress transfer characteristics of underground engineering surrounding rocks cannot be fully realized. Quantification and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

[0049] An underground engineering surrounding rock-stress dual-objective mutual-feedback joint control method, the specific steps are as follows:

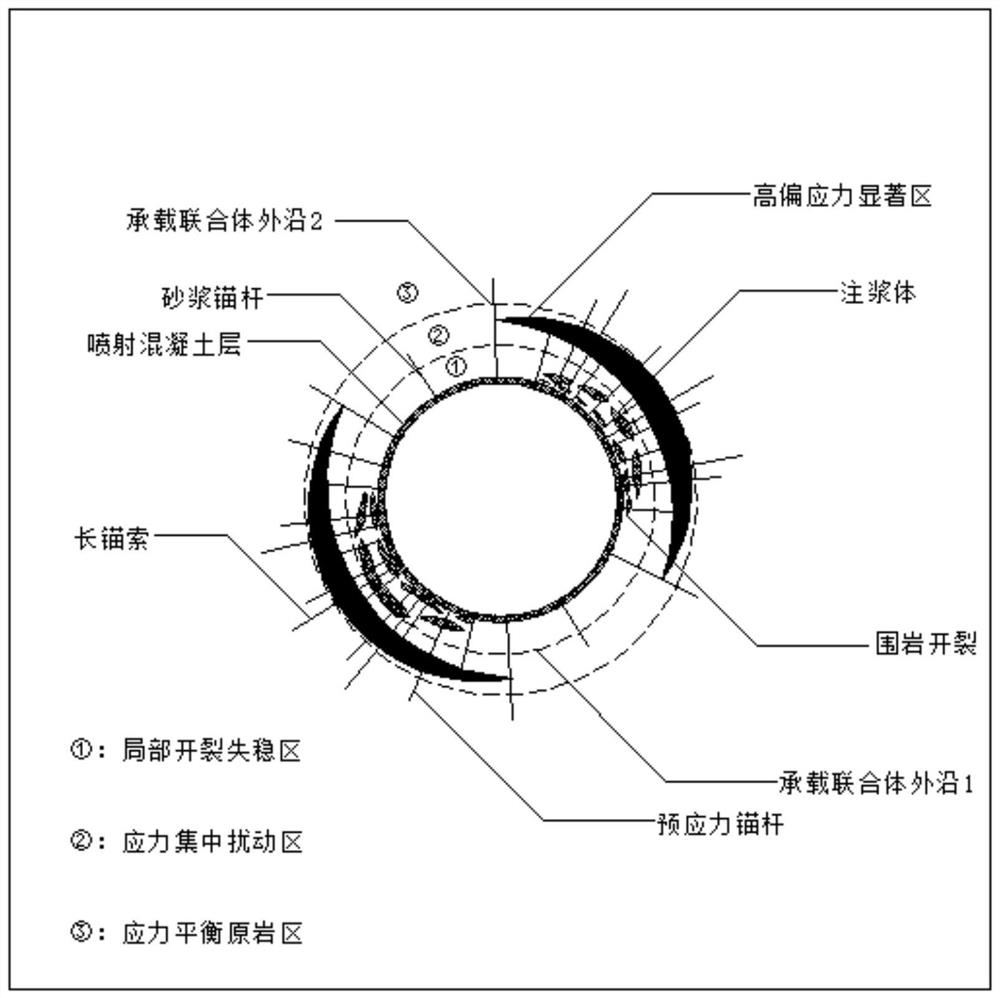

[0050] Step S1, evenly arrange boreholes in the section of the underground engineering cavern, such as figure 1 As shown, through the borehole TV camera technology, the development characteristics of new cracks in the surrounding rock are collected, and the cracking coefficient CDI of the local cracking instability area of the shallow surrounding rock is calculated to determine the excavation layer height of the cavern and the support of the shallow surrounding rock. Type, support timing and support length, this process is briefly described as shallow support and surface consolidation, that is, the purpose of strengthening the surface surrounding rock is achieved by designing shallow support measures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com