Intelligent spot welding rubber support

A rubber bearing and spot welding technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of single detection information, high cost, and difficulty in monitoring the force of the bearing, and achieve the effect of comprehensive detection information and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

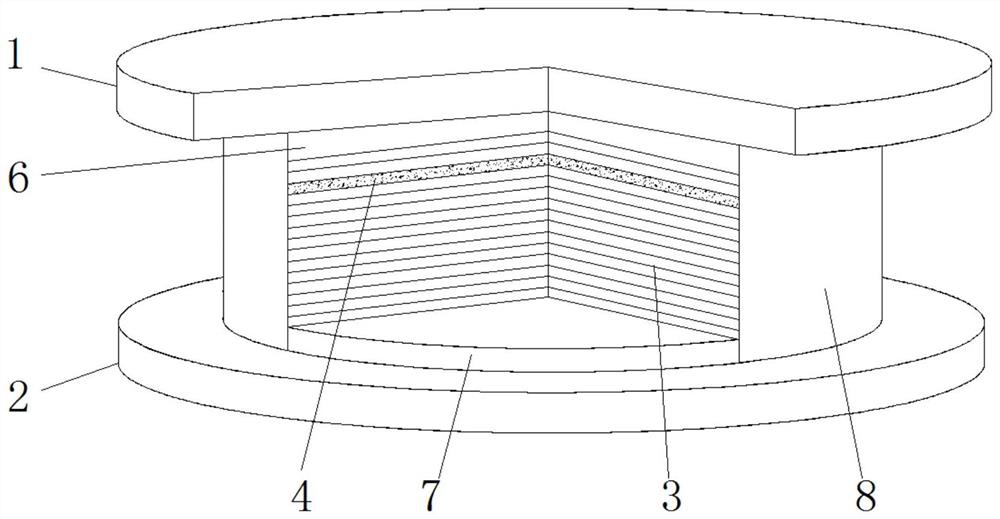

[0033] refer to Figure 1-5 , the present invention provides a spot welding intelligent rubber bearing, comprising a rubber bearing 3, an upper connecting steel plate 1, a lower connecting steel plate 2, several spot welding strain gauge sensors 5, and a protective layer rubber 8;

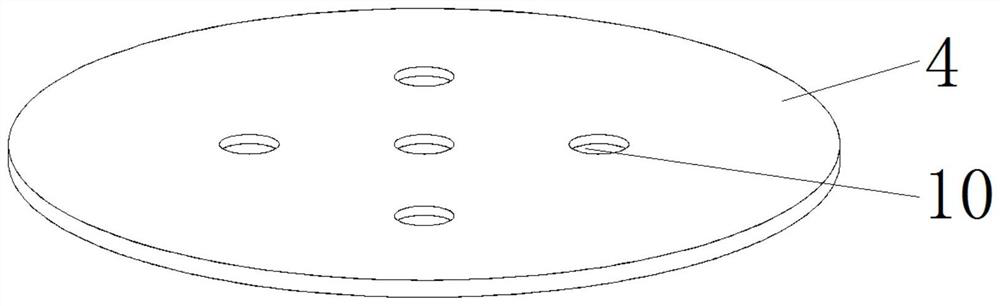

[0034] The top and the bottom of the rubber bearing 3 are respectively provided with an upper sealing plate 6 and a lower sealing plate 7, and the rubber bearing 3 is provided with several rubber plates and steel plates 4 arranged between the rubber plates; the rubber bearing 3 is composed of several rubber plates. Plates are superimposed, and the steel plate 4 is installed between several rubber plates;

[0035] The upper connecting steel plate 1 is fixedly connected to the upper sealing plate 6, and the lower connecting steel plate 2 is fixedly connected to the lower sealing plate 7;

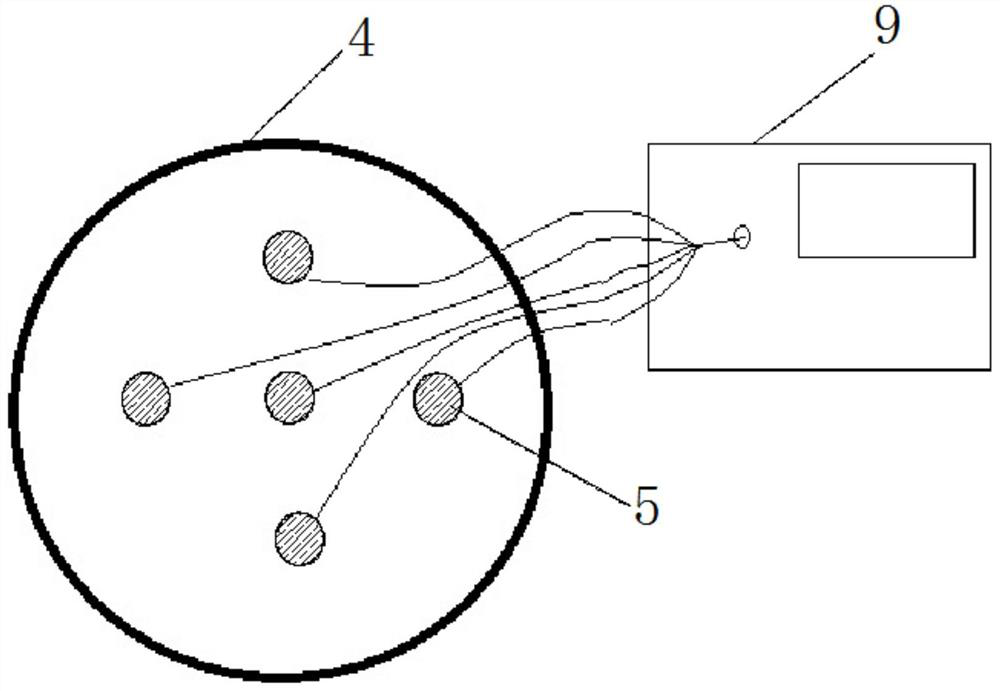

[0036] Several spot welding strain gauge sensors 5 are installed on the steel plate 4;

[0037] The protective...

Embodiment 2

[0049] refer to Figure 6 , the difference between this embodiment and Embodiment 1 is that two steel plates 4 are arranged inside the rubber bearing 3, and the two steel plates 4 are respectively installed in the middle upper section and the middle lower section inside the rubber bearing 3, and the two sets of steel plates 4 are arranged along the The cross section where the midpoint in the height direction of the rubber bearing 3 is located is symmetrically arranged;

[0050] Set up in this way, when the steel plate 4 is set to two, the spot welding intelligent rubber bearing of the present invention is installed in the position where the bridge needs to be supported, and the spot welding strain gauge sensors 5 on the two steel plates 4 are mutually induced, and the force is measured At the same time, the displacement caused by the force can be measured, and the detection information is more comprehensive.

[0051] When the spot welding strain gauge sensor 5 needs to be rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com