Porous granular ammonium nitrate fuel oil explosive and preparation method thereof

A technology of ammonium oil explosives and granular ammonium nitrate, which is applied in the direction of explosives processing equipment, explosives, explosive composite components, etc., can solve the problems of high preparation cost of porous granular ammonium oil explosives, high cost of waste activated carbon treatment, inconvenient transportation, etc. The effect of engineering blasting, reducing the cost of engineering blasting, and reducing the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

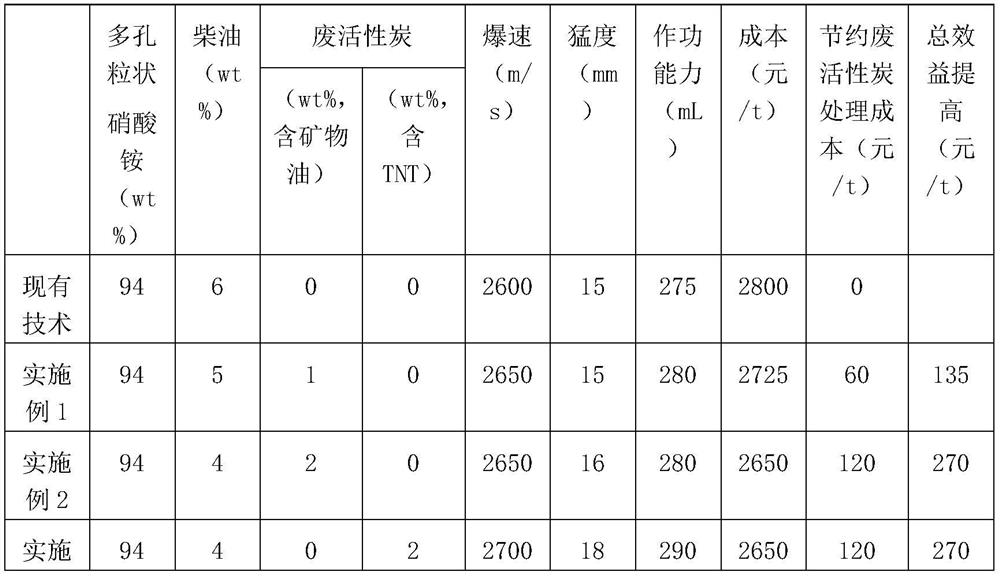

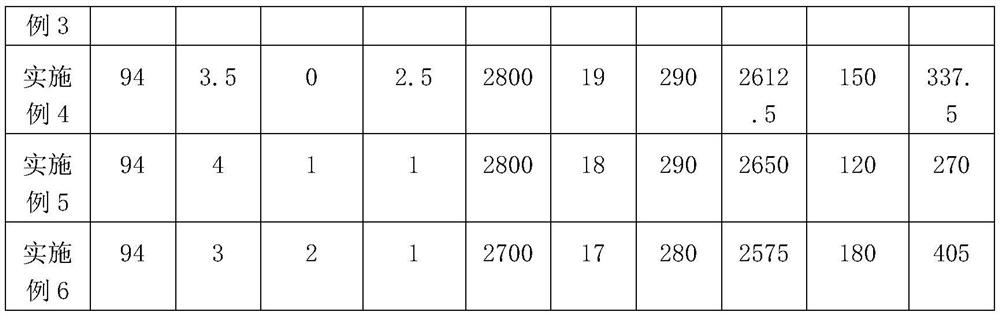

Examples

Embodiment 1

[0023] A porous granular ammonium oil explosive, comprising: 94Kg of porous granular ammonium nitrate, 5Kg of diesel oil, 1Kg of waste activated carbon adsorbed with mineral oil vapor produced in the oil phase production workshop, and 92% of the waste activated carbon has a particle diameter of 1-2.5mm %.

Embodiment 2

[0025] A porous granular ammonium oil explosive, comprising: 94Kg of porous granular ammonium nitrate, 4Kg of diesel oil, 2Kg of waste activated carbon adsorbed with mineral oil vapor produced in the oil phase production workshop, and 93.6% of the waste activated carbon has a particle diameter of 1-2.5mm %.

Embodiment 3

[0027] A porous granular ammonium oil explosive, comprising: 94Kg of porous granular ammonium nitrate, 4Kg of diesel oil, 2Kg of waste activated carbon adsorbed with TNT produced in the wastewater treatment process of the relay detonator production line, and the particle size of the waste activated carbon is 1-2.5mm Particles accounted for 91.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com