Clamp equipment special for fiberboard production

A fibreboard and fixture technology, which is applied in the direction of conveyors, packaging, conveyor objects, etc., can solve the problems of poor clamping, low work efficiency, and low processing accuracy, and achieve simple equipment structure, high work efficiency, and improved practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

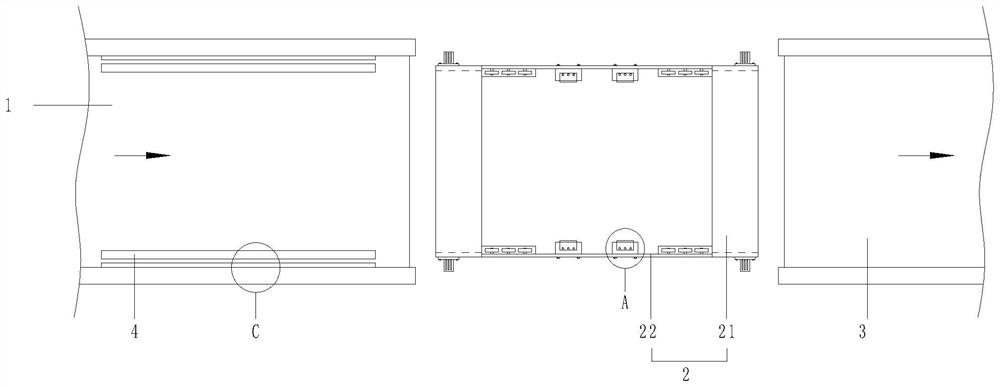

[0026] Such as Figure 1 to Figure 6 As shown, a fixture device specially used for the production of fiberboard, including a transmission mechanism 1, a clamping device 2 and a transmission mechanism 2 3, the clamping device 2 is installed between the transmission mechanism 1 and the transmission mechanism 2 3, and the clamping device 2 includes two clamping mechanisms one 21 and clamping mechanism two 22, clamping mechanism two 22 is installed between the two clamping mechanisms one 21, and two clamping mechanisms one 21 and transmission mechanism one 1 and transmission mechanism respectively Two 3 butts. Specifically, the first transmission mechanism 1 and the second transmission mechanism 3 are both conveyor belts.

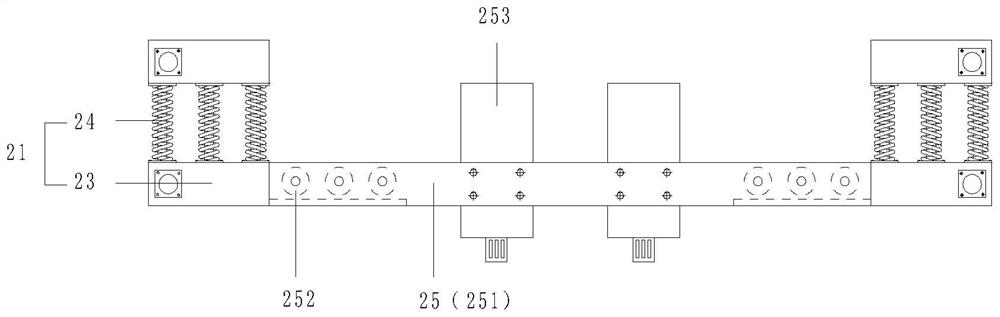

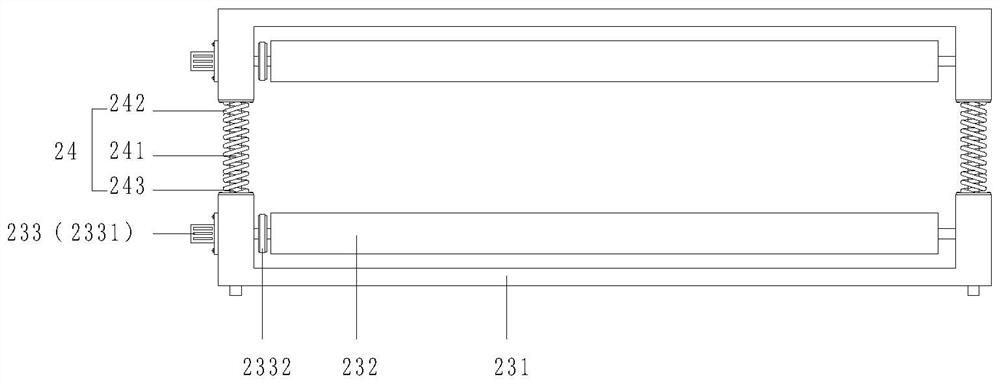

[0027] In this example, if figure 2 with image 3 As shown, the clamping mechanism 1 21 includes two clamping assemblies 1 23 and a plurality of elastic limiters 24, the two clamping assemblies 1 23 are arranged up and down oppositely, and the two ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com