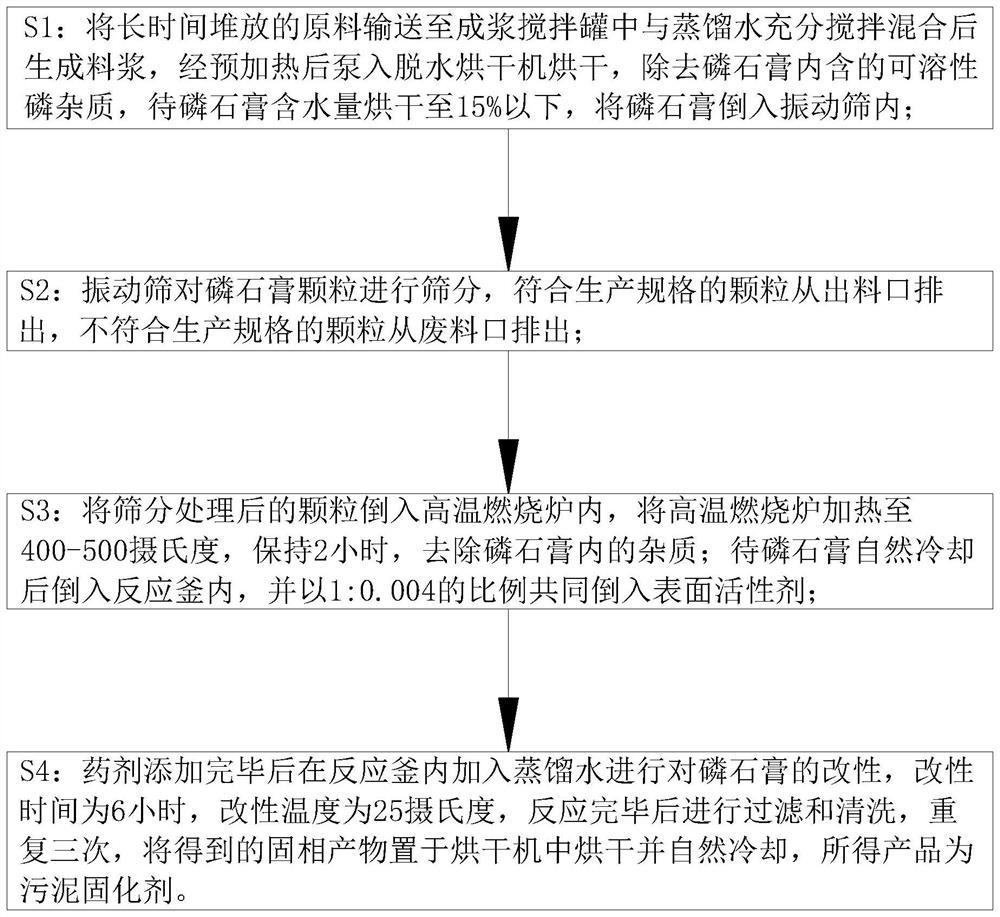

Equipment and method for preparing sludge curing agent based on phosphogypsum solid waste

A technology of sludge curing agent and phosphogypsum, which is applied in the removal of solid waste, chemical instruments and methods, solid separation, etc. phosphogypsum screening yield and other issues, to achieve the effect of increasing the effective screening area, promoting the screening effect, and increasing the effective opening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

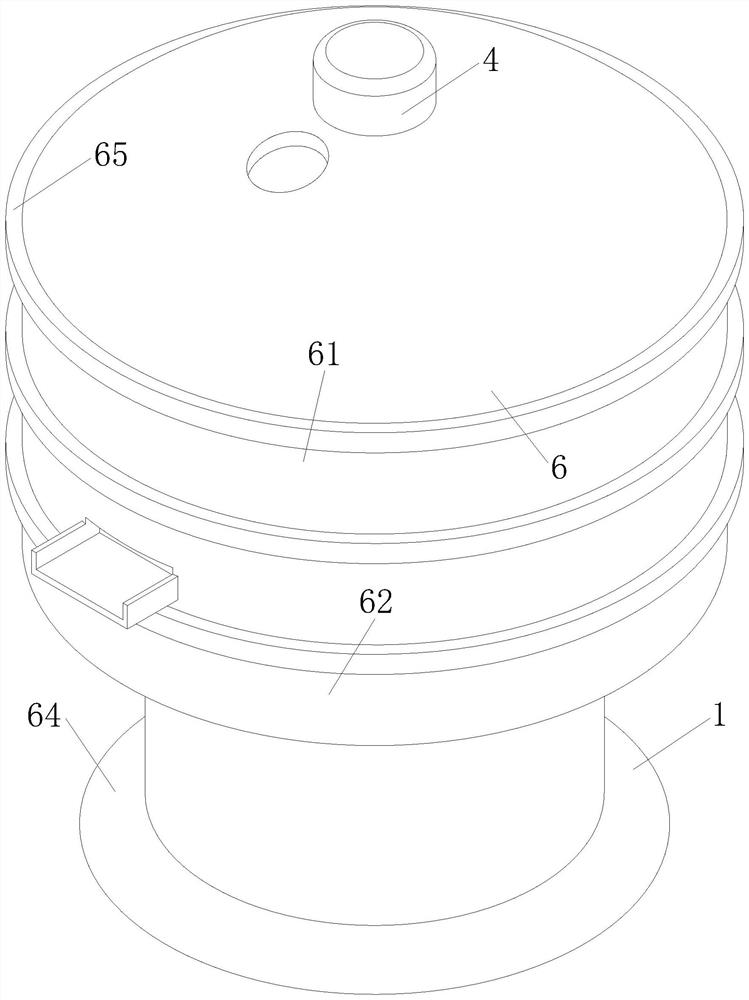

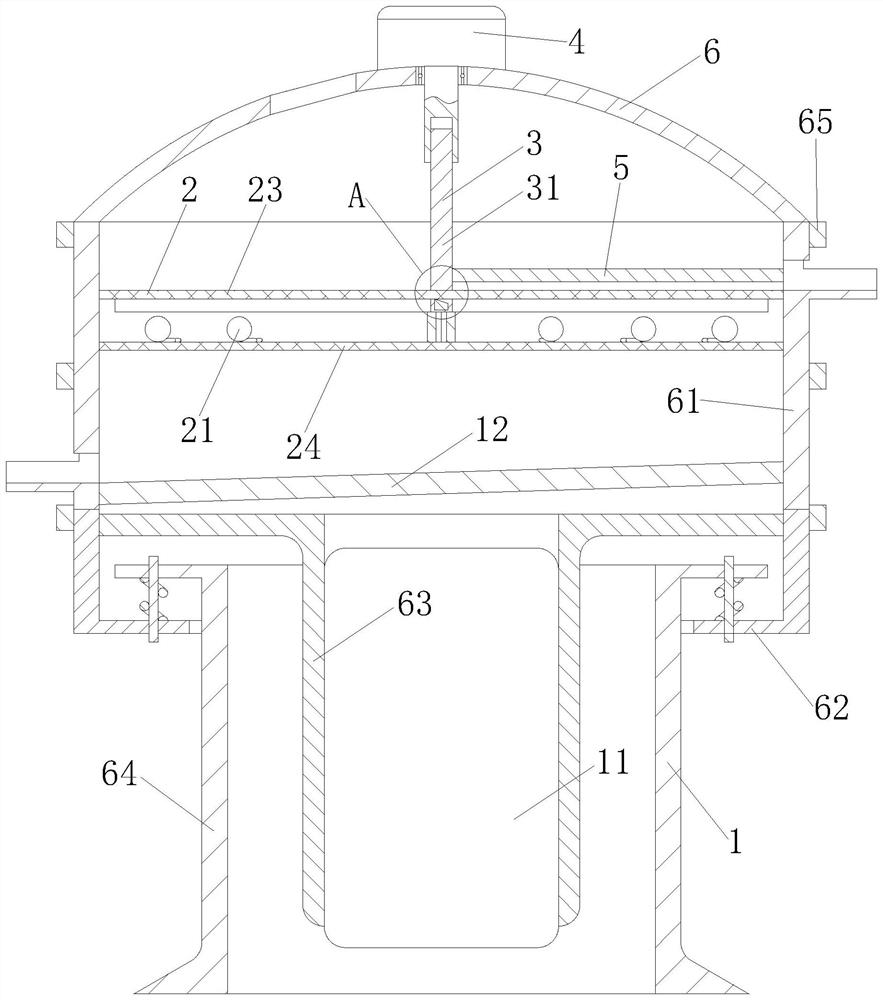

[0054] Such as figure 1 , figure 2 , image 3 and Figure 6 As shown, a kind of sludge solidifying agent preparation equipment based on phosphogypsum solid waste according to the present invention includes a stirring tank, a dryer, a vibrating screen, a high-temperature combustion furnace and a reaction kettle, and the vibrating screen is used for dissolving the phosphogypsum The impurities in the slurry are screened out; the vibrating screen includes:

[0055] subject1;

[0056] A vibrating motor 11, the vibrating motor 11 is installed in the main body 1 close to the bottom position, the vibrating motor 11 is used to generate vibration; the deflector 12, the deflector 12 is fixedly connected in the main body 1, The deflector 12 is located above the vibrating motor 11;

[0057] The sieve 2, the sieve 2 is evenly fixed in the main body 1 and located above the deflector 12, the sieve 2 is driven by the vibration motor 11 to vibrate, and the sieve 2 is composed of an upper ...

no. 2 example

[0081] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 7-9 As shown, the difference between the second embodiment and the first embodiment is that the cleaning rod 32 cleans the upper sieve 23 in a rolling rolling manner;

[0082] Such as Figure 5 , Figure 7 to Figure 9 As shown, the cleaning rod 32 is rotatably connected to the surface of the main shaft 31 and is located between the upper screen 23 and the lower screen 24, and the end of the cleaning rod 32 away from the main shaft 31 is located on the ring slide In the groove 33, the screen cleaning rod 32 is connected with the annular chute 33 through a gear and a rack;

[0083] The surface of the outer ring of the cleaning rod 32 is roughened.

[0084] When in use, the main shaft 31 drives the cleaning rod 32 to move in a circle around the main shaft 31. The gear at the end of the cleaning rod 32 away from the main shaft 31 meshes with the rack in the annular chute 33, and the gear rolls on the rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com