A waste tire fine rubber powder classifier

A waste tire, fine-grade technology, applied in the field of resource recycling and comprehensive utilization, can solve the problems of fine rubber powder particles escaping the environment, difficult to solve dust-proof sealing of vibrating screen, environmental noise pollution, etc., to increase the effective screening area, increase Efficiency, avoid the effect of coke and carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

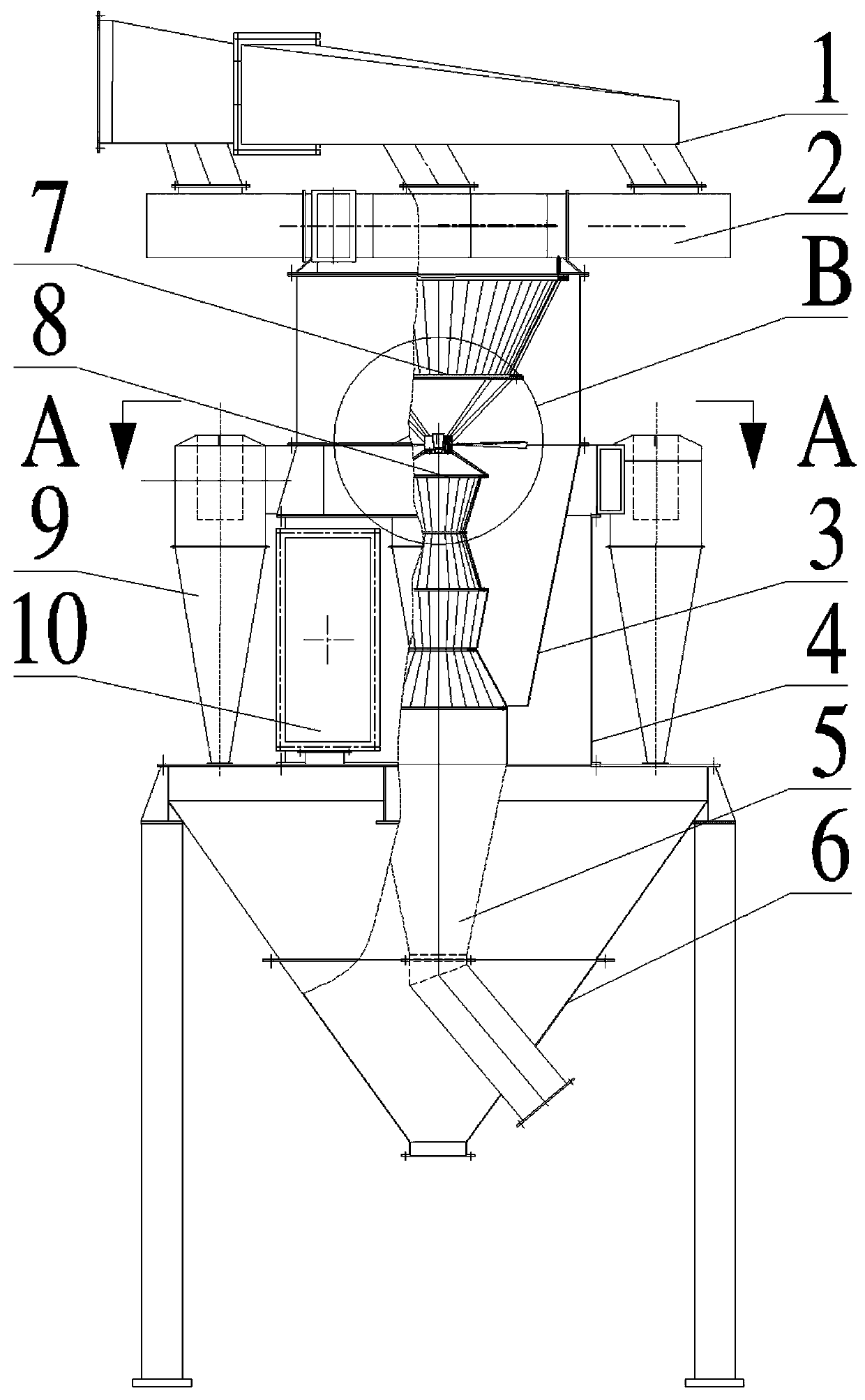

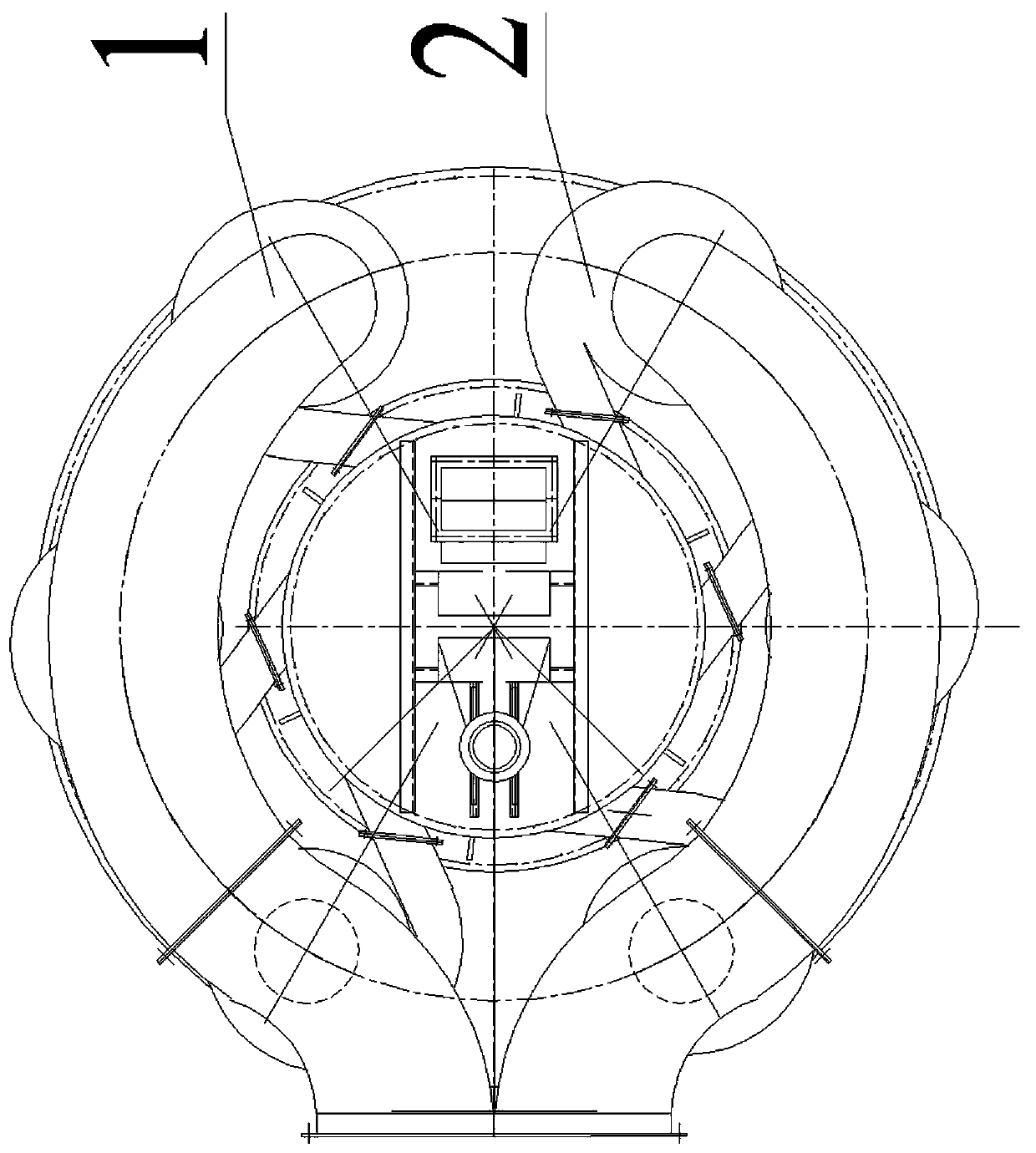

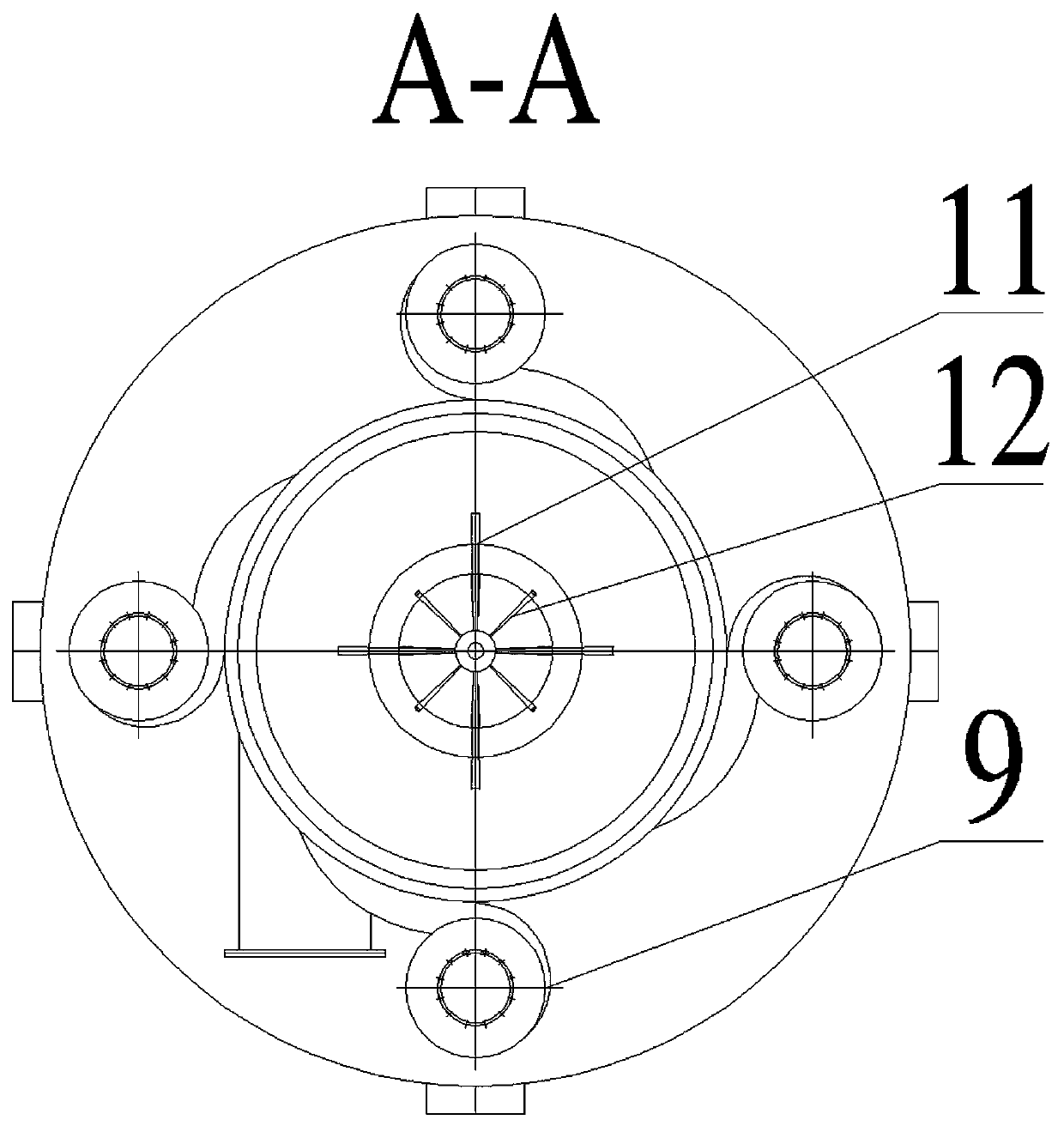

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a fine rubber powder classifier for waste tires is characterized in that it includes a sump 1, a spiral inlet assembly 2, a diverter skirt 3, a cylinder 4, a high-fine rubber powder bin 5, and a fine rubber powder bin 6. Fine grade circular screen cage 7, high fine grade circular screen cage 8, cyclone separator 9, blowback port 10, cross balance fin 11, elastic rod 12.

[0023] The sump 1 is connected to the spiral inlet assembly 2, and the spiral inlet assembly 2 is connected to the upper part of the fine-grade circumferential screen cage 6 along the tangential direction of the circumference of the fine-grade circumferential screen cage 6, and the fine-grade circumferential screen The cage 7 and the high-definition circular screen cage 8 are installed on the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com