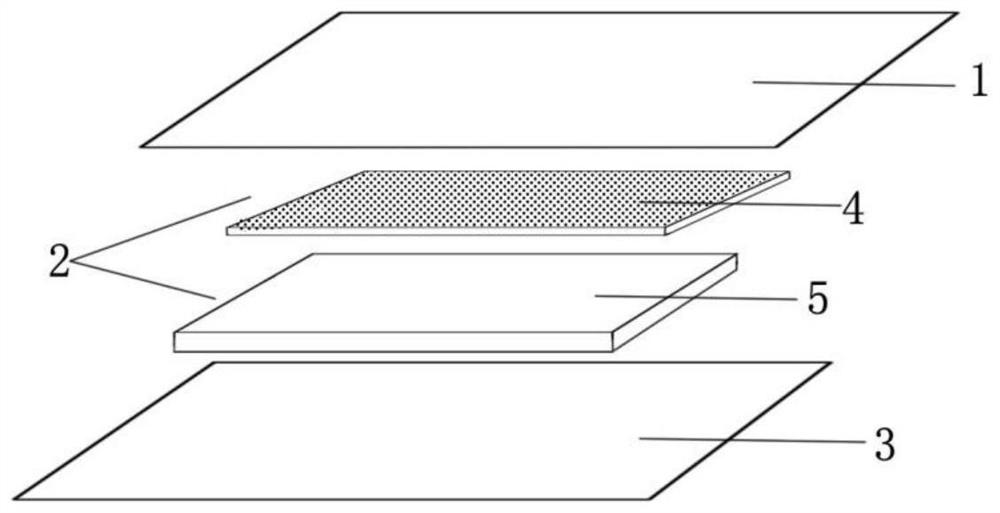

Composite multi-layer dressing as well as preparation method and application thereof

A double-layer composite and polyvinyl alcohol technology, which is applied in dressings, non-adhesive dressings, coatings, etc., can solve the problems of cytotoxicity, removal of easy adhesions, adverse reactions of the human body, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

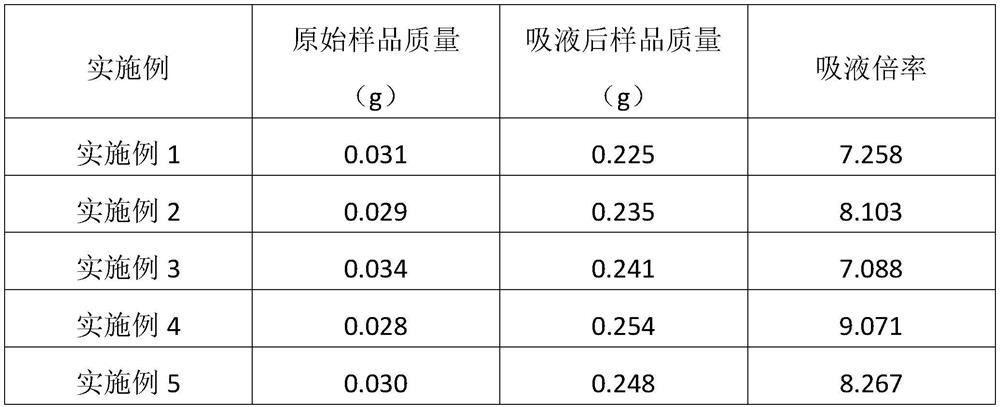

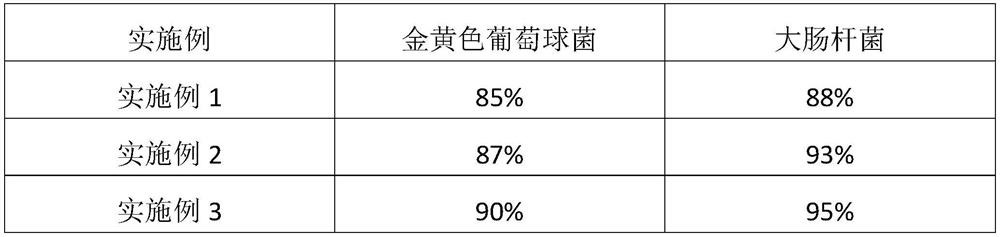

Embodiment 1

[0038] Dissolve an appropriate amount of chitosan powder in 1vol% acetic acid solution, stir at room temperature for about 12 hours, configure a chitosan solution with a mass fraction of 2%, and let it stand for degassing for 2 hours; take a certain amount of polyvinyl alcohol and dissolve it in In deionized water, heat and stir in a water bath at 60° C. for about 2 hours until the polyvinyl alcohol powder is completely dissolved to obtain a polyvinyl alcohol solution with a mass fraction of 8%. Mix the chitosan and polyvinyl alcohol solution at a ratio of 1:9, stir at room temperature for about 10 hours, and leave to defoam for 2 hours to obtain a transparent polyvinyl alcohol / chitosan spinning solution. Electrospinning was carried out in an environment with a temperature of about 25°C and a humidity of 35RH%. The spinning process parameters are as follows: the spinning voltage is 12KV, the liquid supply speed is 0.4mL / h, and the receiving distance is 12cm. The thickness of ...

Embodiment 2

[0043] Dissolve an appropriate amount of chitosan powder in 1vol% acetic acid solution, stir at room temperature for about 12 hours, configure a chitosan solution with a mass fraction of 3%, and let it stand for degassing for 2 hours; take a certain amount of polyvinyl alcohol and dissolve it in In deionized water, heat and stir in a water bath at 60° C. for about 2 hours until the polyvinyl alcohol powder is completely dissolved to obtain a polyvinyl alcohol solution with a mass fraction of 11%. Mix chitosan and polyvinyl alcohol solution at a ratio of 3:7, stir at room temperature for about 10 hours, and stand for defoaming for 4 hours to obtain a transparent polyvinyl alcohol / chitosan spinning solution. Electrospinning was carried out in an environment with a temperature of about 30°C and a humidity of 40RH%. The spinning process parameters are as follows: the spinning voltage is 16KV, the liquid supply speed is 0.8mL / h, and the receiving distance is 16cm. The thickness of...

Embodiment 3

[0048] Dissolve an appropriate amount of chitosan powder in 1vol% acetic acid solution, stir at room temperature for about 12 hours, configure a chitosan solution with a mass fraction of 4%, and let it stand for degassing for 2 hours; take a certain amount of polyvinyl alcohol and dissolve it in In deionized water, heat and stir in a water bath at 60° C. for about 2 hours until the polyvinyl alcohol powder is completely dissolved to obtain a polyvinyl alcohol solution with a mass fraction of 14%. Mix chitosan and polyvinyl alcohol solution at a ratio of 5:5, stir at room temperature for about 10 hours, and stand for defoaming for 4 hours to obtain a transparent polyvinyl alcohol / chitosan spinning solution. Electrospinning was carried out in an environment with a temperature of about 35°C and a humidity of 45RH%. The spinning process parameters are as follows: the spinning voltage is 20KV, the liquid supply speed is 1.0mL / h, and the receiving distance is 20cm. The thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com