Positive pressure feedback jet pulse water dropper and drip irrigation system

A jet and pulse technology, which is applied in the field of positive pressure feedback jet pulse dripper and drip irrigation system, can solve the problems of incomplete deflection of water flow, small amplitude, large dripper flow rate, etc., and achieve the effect of convenient construction and installation and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

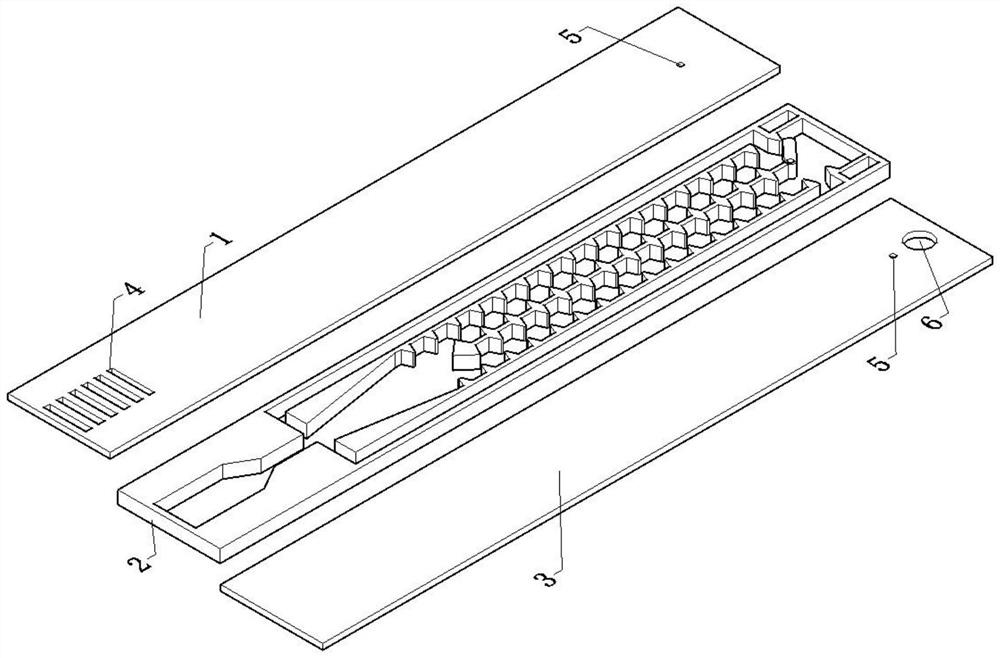

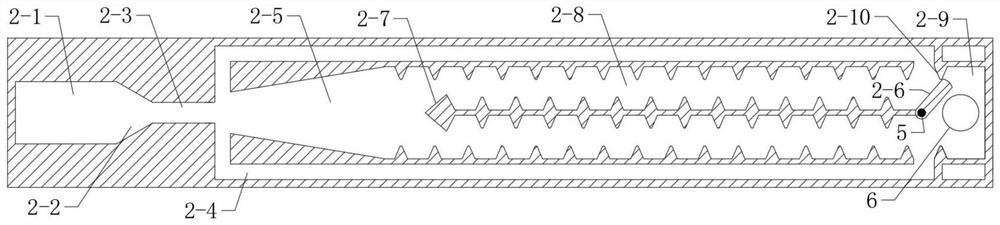

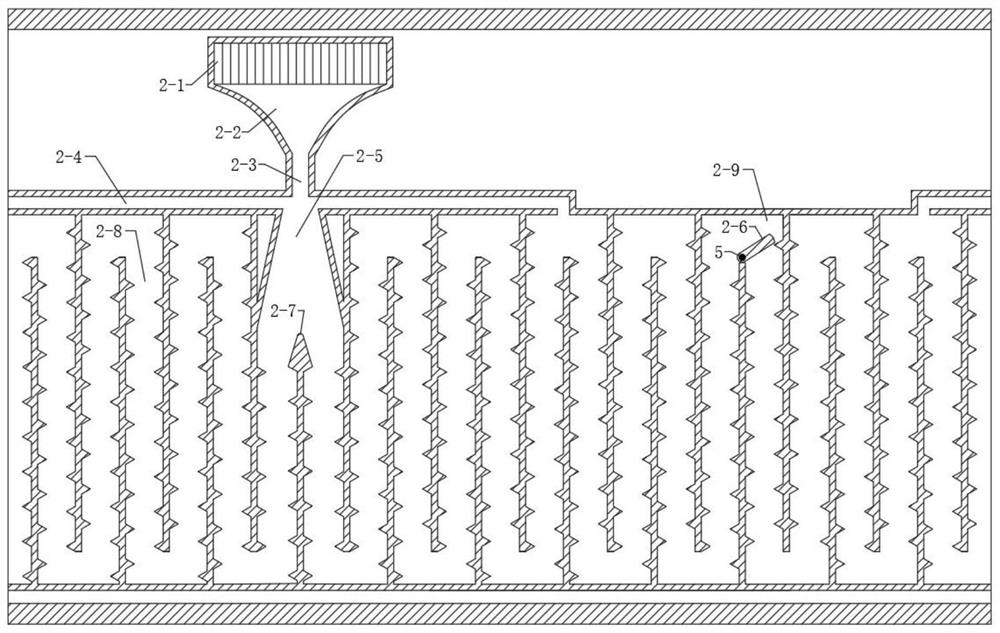

[0037] Such as Figure 1-Figure 2 As shown, the present embodiment provides a positive pressure feedback jet pulse dripper, preferably a sheet-type positive pressure feedback jet pulse dripper, which mainly includes an upper cover 1, a main body 2 and a lower cover 3; There is a water filter port 4, and the lower cover plate 3 is provided with a water outlet hole 6; the main body 2 includes a water inlet tank 2-1, a shrink tube 2-2, a jet tube 2-3, a water pressure feedback tube 2-4, and a jet cavity 2-5 , water diversion plate 2-6, splitter splitter 2-7, flow channel 2-8, water outlet cavity 2-9, limit block 2-10; water inlet tank 2-1 is located at the front end of main body 2, water inlet tank 2-1 A shrinking tube 2-2 with a large front and a small rear is connected afterwards, and a rectangular jet tube 2-3 is connected after the shrink tube 2-2, and a trapezoidal jet cavity 2-5 with a small front and a large rear is connected after the jet tube 2-3; A hole is respectively...

Embodiment 2

[0045] This embodiment is an improvement made on the basis of Embodiment 1, and its improvements are as follows: Figure 3-Figure 4 As shown, the positive pressure feedback jet pulse dripper is a cylindrical positive pressure feedback jet pulse dripper, and the splitter 2-7 of the cylindrical positive pressure feedback jet pulse dripper divides the jet chamber 2-5 into two channels, and the two streams The front ends of the channels 2-8 communicate with two adjacent channels respectively, wherein the flow channels 2-8 may include a plurality of vertical channels connected in sequence from end to end, and the hydraulic feedback pipes 2-4 are arranged around the circumference.

[0046] When a cylindrical positive pressure feedback jet pulse dripper is set in the drip irrigation pipeline, the outer surface of the cylindrical positive pressure feedback jet pulse dripper is embedded on the inner wall of the drip irrigation pipeline, and corresponds to the center of the water outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com