Method for long-distance replacement of damaged wire on strain tower side among multiple split wire gears

A damaged wire, long-distance technology, used in devices to maintain the distance between parallel conductors, cable suspension devices, overhead lines/cable equipment, etc. , Affect construction and wire quality and other issues, to reduce the high-altitude action time, improve convenience and safety, and reduce the workload of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

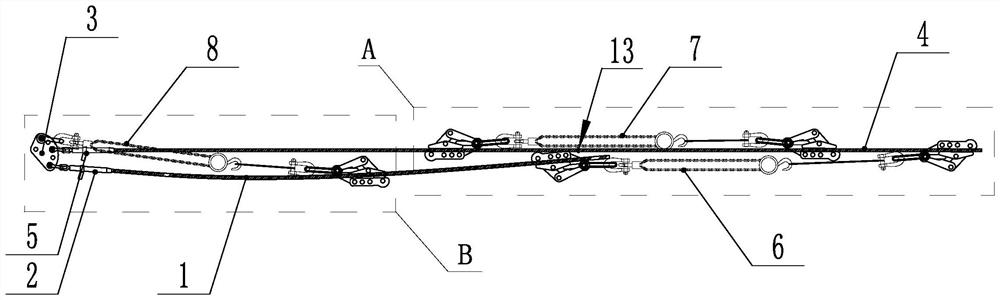

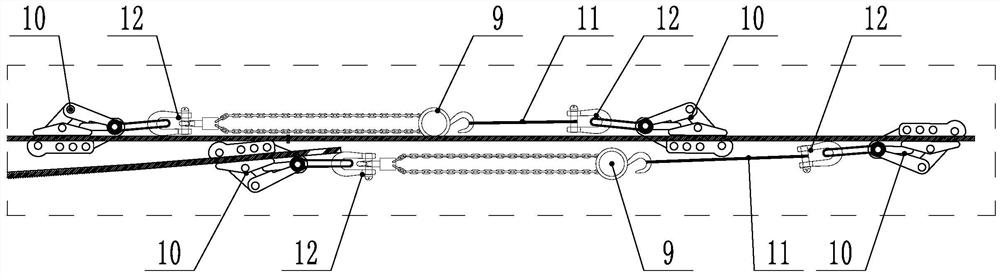

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

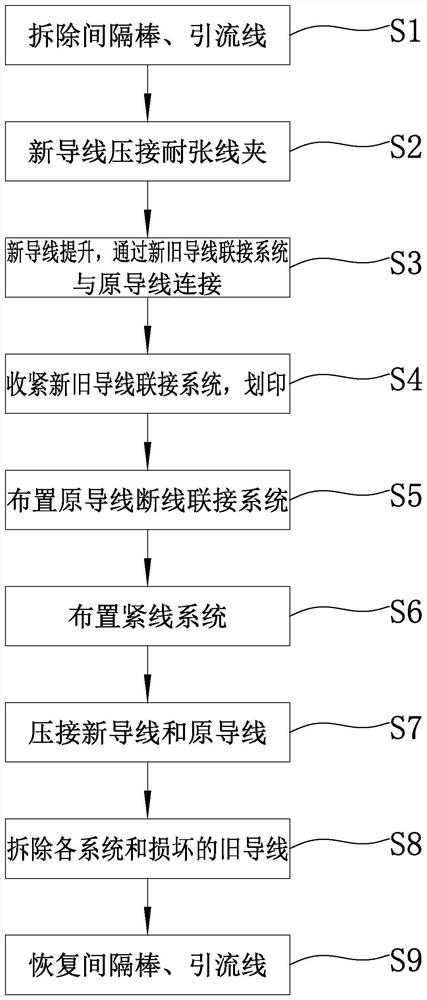

[0030] Such as Figure 1-4 As shown, the method for replacing the damaged wire on the side of the strain tower over a long distance between multiple split wire stalls, the process includes the following steps:

[0031] S1: The front 3 spacers and wire anti-vibration hammers on the side need to be replaced when the outgoing line is removed. Tension clamp 2 is connected, and the jumper is temporarily fixed on other sub-conductors;

[0032] S2: New conductor 1 ground crimping strain clamp 2;

[0033] S3 At the two sides and the middle position of the replacement wire section, the new wire 1 is manually raised to the height of the original wire 4 of the part to be removed through the rubber pulley with the transfer rope, and the strain clamp 2 is connected to the adjustment plate 3, and the new and old wires are connected. System 6 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com