Multidirectional special-shaped feed structure and processing technology thereof

A feeding and special-shaped technology, which is applied in the direction of antenna grounding switch structure connection, circuit, electrical components, etc., can solve the problems of passive intermodulation, etc., and achieve the effects of improving production efficiency, simplifying the process flow, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The multi-directional special-shaped feed structure in this embodiment includes a feed body in the form of a closed cavity and at least two feed interfaces. The inner cavity of the feed body is provided with at least two multi-directional special-shaped feature structures. The characteristic structure is matched and connected with the feeding interface one by one, and the feeding interface realizes the internal and external interconnection of the feeding structure by welding with the radio frequency connector;

[0032] The multidirectional special-shaped feature structure is provided with a mounting hole matching the shape of the end of the inner conductor of the radio frequency connector, and a vertical threaded hole is opened through the mounting hole, and the end of the inner conductor of the radio frequency connector is inserted into the In the mounting hole, the vertical threaded hole is pierced with a positioning pin, and the inner conductor of the radio frequency ...

Embodiment 2

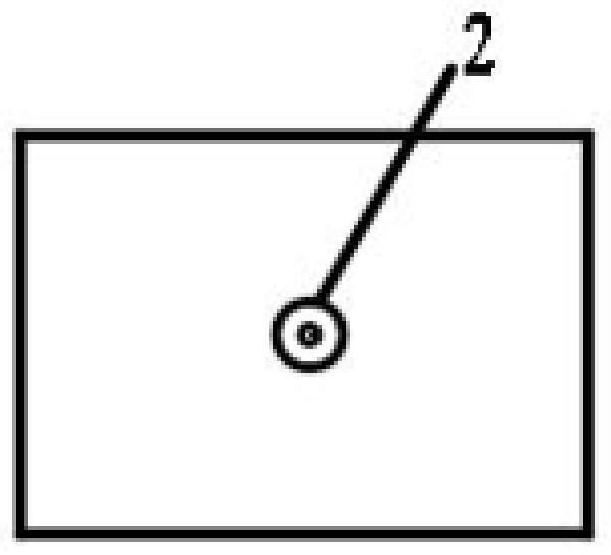

[0040] Such as figure 1 , 2 As shown, the multi-directional special-shaped feeding structure of this embodiment includes a feeding interface 1 , a feeding interface 2 and a feeding body 3 . The inner conductor of the feed interface 2 is provided with a groove 21 . The feeder body 3 contains two multi-directional special-shaped characteristic structures 51 and 52, and the external dimension accuracy of the two characteristic structures is required to be ±0.01mm. The characteristic structure is provided with interface mounting holes 511 and 521, lower vertical holes 512 and 522, and upper vertical threaded holes 513, wherein the lower vertical holes 512 and 522 are used for pre-soldering, and the upper vertical threaded hole 513 is used for filling positioning pins 7 . Positioning holes 53 are provided on the housing 5 for installing pins to position the cover plate and the welding piece. The two feeder interfaces are interconnected with the characteristic structure through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com