Positioning layout optimization method for ceramic core in precision casting hollow turbine blade shell

A technology for optimizing the layout of turbine blades, which is applied in the field of optimizing the positioning and layout of ceramic cores inside the shell of precision-cast hollow turbine blades. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

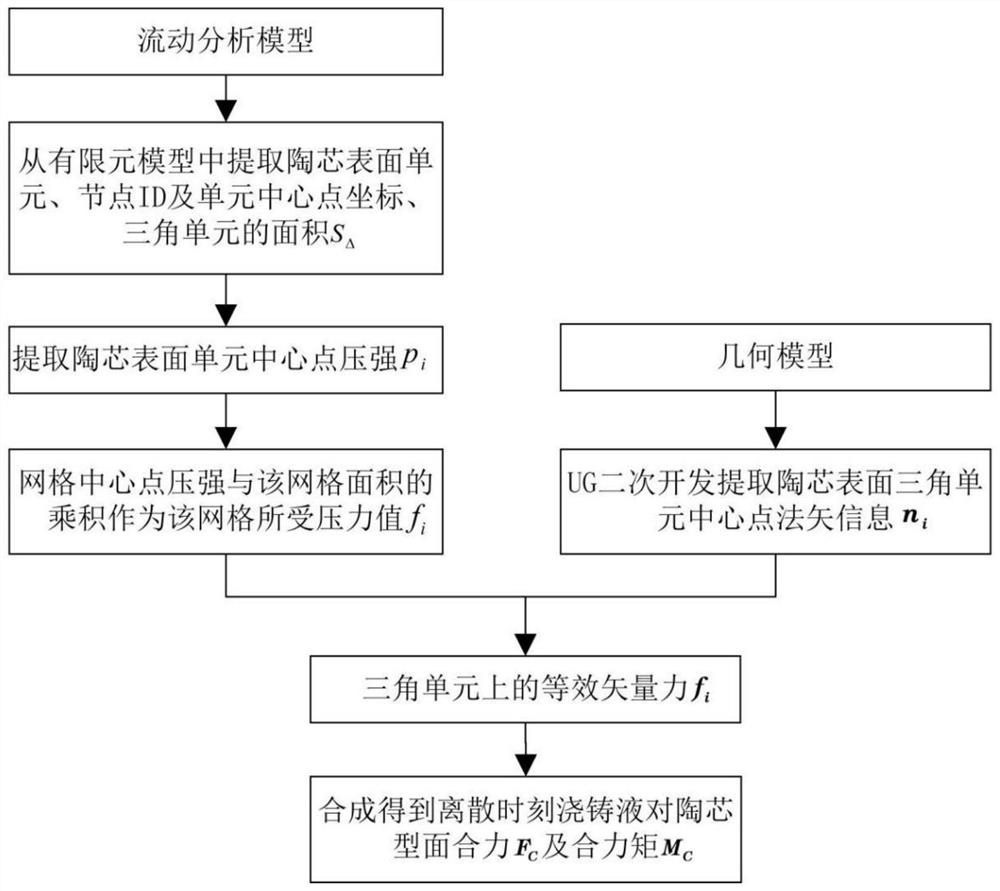

[0042] Step 1. Based on the fluid simulation computing platform, calculate the node pressure value formed by the metal casting liquid on the surface of the ceramic core during the blade casting process. The specific method is:

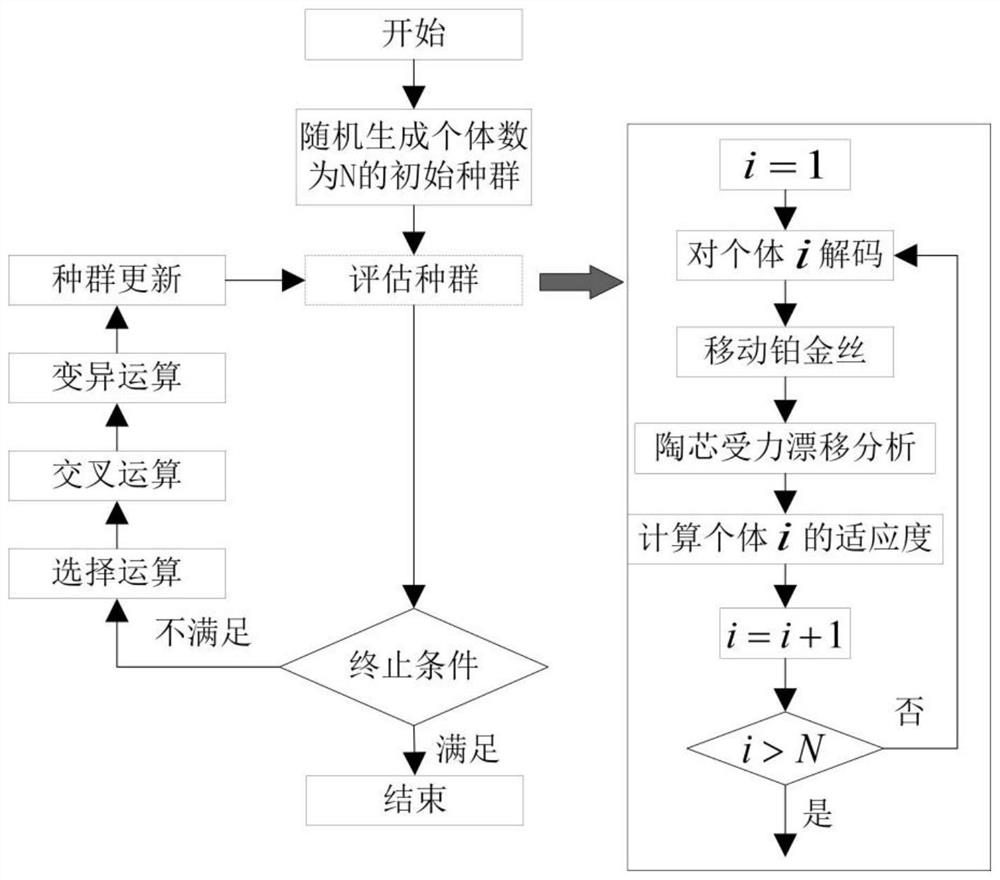

[0043] The blade and ceramic core are modeled in the three-dimensional drawing software UG, and the geometric model assembly relationship between the blade and the ceramic core is as follows: image 3 As shown; then the finite element meshing is carried out in HyperMesh, in which, the number of blade (cavity) grid nodes is 54811, and the number of elements is 289238; after that, the finite element model of the blade and ceramic core is imported The fluid simulation calculation platform ANSYS, selects the multiphase flow and turbulence calculation model, sets the casting speed to 0.45m / s, uses the top injection casting method to simulate the blade casting process, and obtains the pressure of the central node of each grid on the surface of the ceramic cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com