Natural milling and coating process for high-grade nappa elastic leather

A kind of elastic and leather technology, applied in the direction of leather softening, leather drying, leather impregnation, etc., can solve the problems of coating stickiness, substandard physical properties, low sorting rate, etc., to improve grade and grade, natural finishing style, high grade The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

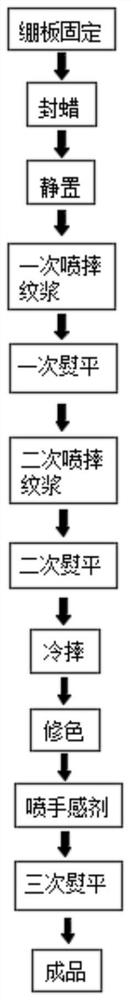

[0040] like figure 1 As shown, the invention provides a kind of high-grade Napa stretch leather natural wrestling pattern finishing process, comprises the following steps:

[0041] 1) Stretch plate fixation: put the grain surface of the leather embryo on the horizontal stretcher machine, the whole leather embryo should be stretched flat without any wrinkles, the clamping distance is 3 cm, rotate 2 times, 6 minutes per circle, and then take it off ;

[0042] 2) Sealing wax: Spray the back seal slurry evenly on the leather embryo treated in step 1) with a spray machine, spray twice, and dry;

[0043] 3) Stand still: put the skin embryo after step 2) to stand for 2 hours;

[0044] 4) One-time spraying of the grain slurry: the grain slurry is evenly sprayed on the leather embryo after step 3) with a spray machine, sprayed twice, and dried;

[0045] 5) One-time ironing: put the leather embryo treated in step 4) face up on the conveyer belt of the ironing machine, and iron it smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com