Method for producing chitosanase by using bacteria

A chitosanase and bacteria technology, applied in the field of microbial fermentation, can solve the problems of insufficient enzyme activity and low enzyme production, and achieve the effect of improving the technical level and high enzyme production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

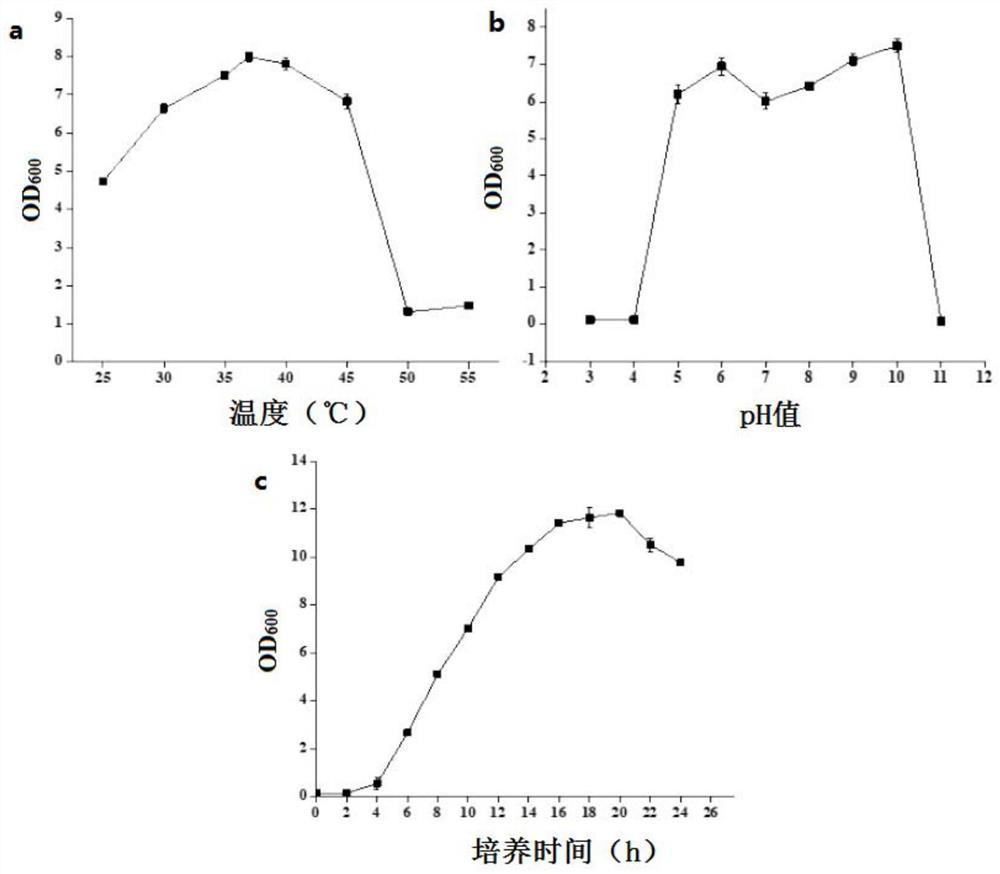

[0021] Embodiment 1: Optimization of strain growth conditions

[0022] (1) The influence of culture temperature on the growth of bacterial strains

[0023] Culture temperature is an important factor affecting the growth of bacteria. Within a certain temperature range, the biomass of bacteria will increase continuously with the increase of temperature. When the temperature is too low or too high, the growth of bacteria will be affected. Take out the glycerin tube strain from the liquid nitrogen tank at -80°C, and dip the glycerin tube strain Bacillus licheniformis strain BCRC11702 with an inoculation loop or a sterile bamboo stick. g / L, draw a line on the blank slant of pH 6-7.5, incubate at 30-40°C for 12-24 hours, and set aside. Take 3mL of sterile normal saline to wash the cultivated slant, and take an inoculation volume of 1% by volume to inoculate to the formula of yeast extract 5-10g / L, peptone 10-20g / L, sodium chloride 10.0-15.0g / L L in liquid medium with a pH of 6-7,...

Embodiment 2

[0029] Embodiment 2: Optimization of fermentation conditions

[0030] Using the seed solution obtained from the activation of the bacterial strain under the optimal conditions of Example 1 to inoculate and ferment in the liquid medium containing yeast, the influence of different process conditions on the production of chitosanase by the bacterial strain was investigated.

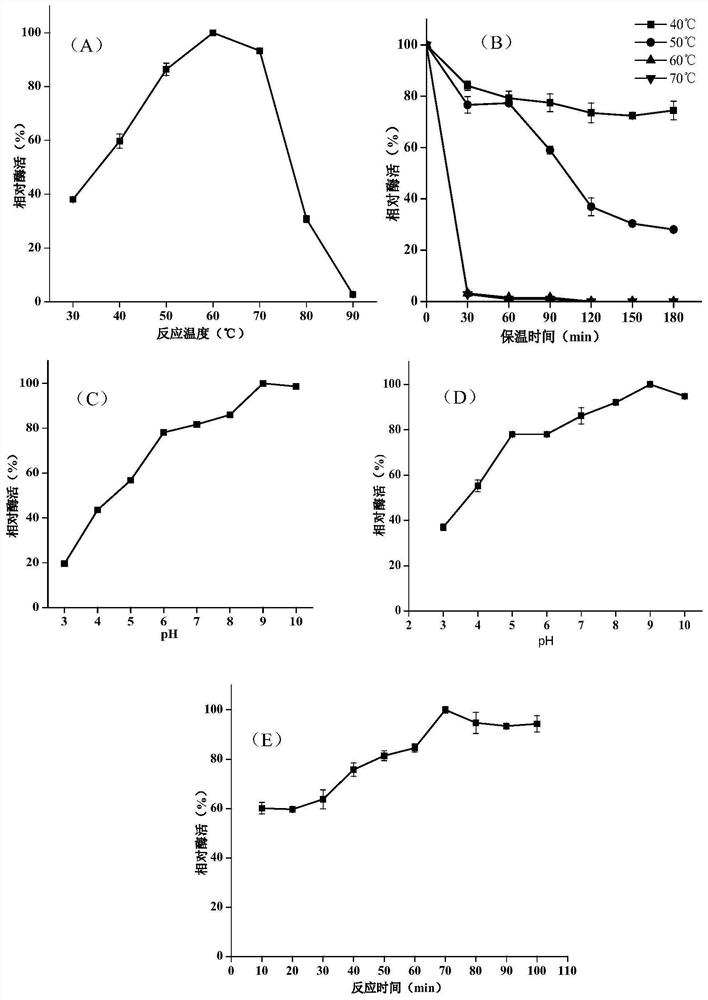

[0031] (1) Effects of different fermentation times on strains producing chitosanase

[0032] The result is as figure 2As shown in (A): when the culture time is 0-36h, the enzyme activity gradually increases with the prolongation of the fermentation time, and reaches the highest level when the enzyme is produced for 36h, and the enzyme activity is 7.82U / mL at this time; after that With the prolongation of fermentation time, the enzyme activity began to decrease gradually. At 72 hours of fermentation, the enzyme activity was 4.9U / mL, and the enzyme activity level decreased by 37%. The reason may be that in ...

Embodiment 3

[0043] Embodiment 3: Utilize the method that bacterium produces chitosanase

[0044] Step 1: Activation of the strain:

[0045] Take the bacteria from the glycerol tube of Bacillus licheniformis strain BCRC 11702, put them on the blank slant medium, and culture them by streaking at 30°C for 16 hours. The formula of the blank slant medium is: yeast extract 5.0~10.0g / L , peptone 10.0-20.0g / L and sodium chloride 5.0-10.0g / L, its pH value is 6; then inoculated in a shaker flask containing seed medium, and cultured at 30°C at a shaking rate of 100r / min 15h, the formula of the seed medium is: yeast extract 5.0-10.0g / L, peptone 10.0-20.0g / L and sodium chloride 5.0-10.0g / L, the pH value is 6, and the seed liquid is obtained;

[0046] Step 2: Fermentation culture:

[0047] Put the seed liquid into the shake flask containing the fermentation medium according to 5% volume percentage, and ferment and cultivate it at 28°C and the shaking speed of 180r / min for 18h; wherein, the formula of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap