Efficient resource utilization method for fallen leaves

A technology of recycling and defoliation, applied in the field of coking, can solve the problems of wasting resources, long time, polluting the environment, etc., and achieve the effects of high recovery efficiency and conversion rate, reducing coking costs, and reducing the amount of coking coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

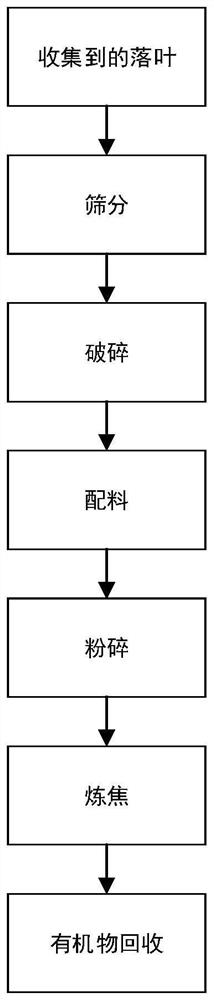

Image

Examples

Embodiment 1

[0022] The collected fallen leaves are screened by a vibrating sieve, and the aperture of the vibrating screen is 20 mm; the screened fallen leaves are crushed by a jaw crusher, and the size is less than 20 mm; the crushed fallen leaves are mixed with other coking coal, and the fallen leaves are The proportion is 1% of the total weight; the mixture of fallen leaves and coking coal is pulverized by the original pulverizer in a coking plant; the pulverized mixture of fallen leaves and coking coal is put into a coke oven for coking.

[0023] During the coking process, the fallen leaves are transformed into coke that meets the needs of blast furnace production along with the coking coal, and coke oven gas with high calorific value and by-products such as tar and crude oil that can be used as chemical raw materials are produced, so that the organic matter and heat of fallen leaves can be fully recycled. A ton of coke can reduce the amount of coking coal by 1kg to 2kg. The calorific...

Embodiment 2

[0025] The collected fallen leaves are screened by a vibrating sieve, and the aperture of the vibrating screen is 40mm; the screened fallen leaves are crushed by a jaw crusher, and the size is less than 20mm; the crushed fallen leaves are mixed with other coking coal, and the fallen leaves are The proportion is 0.5% of the total weight; the mixture of fallen leaves and coking coal is pulverized by the original pulverizer in a coking plant; the pulverized mixture of fallen leaves and coking coal is put into a coke oven for coking.

[0026] During the coking process, the fallen leaves are transformed into coke that meets the needs of blast furnace production along with the coking coal, and coke oven gas with high calorific value and by-products such as tar and crude oil that can be used as chemical raw materials are produced, so that the organic matter and heat of fallen leaves can be fully recycled. A ton of coke can reduce the amount of coking coal by 0.5kg to 1kg.

Embodiment 3

[0028] The collected fallen leaves are screened by vibrating sieve, and the aperture of the vibrating screen is 50 mm; the screened fallen leaves are crushed by jaw crusher, and the size is less than 20 mm; the crushed fallen leaves are mixed with other coking coal, and the fallen leaves are The proportioning ratio is 0.2% of the total weight; the mixture of fallen leaves and coking coal is pulverized by an original pulverizer in a coking plant; the pulverized mixture of fallen leaves and coking coal is put into a coke oven for coking.

[0029] During the coking process, the fallen leaves are converted together with the coking coal into coke that meets the needs of blast furnace production, and coke oven gas with high calorific value and by-products such as tar and crude oil that can be used as chemical raw materials are produced, so that the organic matter and heat of fallen leaves can be fully recycled. A ton of coke can reduce the amount of coking coal by 0.2kg to 0.5kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com