Method for promoting maturing process of aerobic compost and improving compost quality

An aerobic composting and decomposing technology, which is applied in the field of fermented composting and organic waste resource utilization, can solve the problems of polluted soil, heavy metal content exceeding the standard, and the toxic effect of fermenting microorganisms, and achieve high cation exchange capacity, large specific surface area, The effect of catalyzing the formation and accumulation of humic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

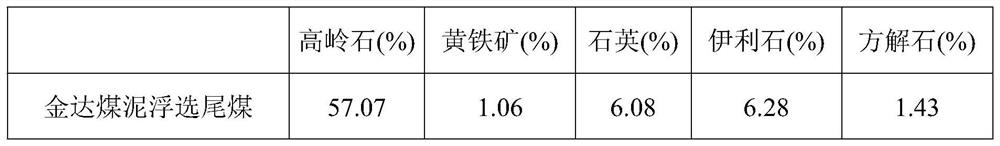

Embodiment 1

[0041] Corn stalks, chicken manure and slurry-state decomposing-promoting mineral particles were used as raw materials for fermentation in a 100L fermenter indoors. First, mix the slurry-state decomposing-promoting mineral granular minerals with corn stalks, then add a certain quality of chicken manure, and adjust the carbon-nitrogen ratio to 42. Then add fermentation bacteria liquid (1L / fresh material), and further add appropriate amount of water to adjust the moisture content to about 60%. Take no decomposing-promoting mineral particles as the control group (CK), add 5% decomposing-promoting mineral particles (accounting for 5% of the fresh weight of the total material) as test 1 (T1), add 10% decomposing-promoting minerals Pellets (10% of the fresh weight of the total material) are test 2 (T2). The fermentation period is 41 days. Detect the nitrogen content of the initial mixture and the fermented and decomposed products, as shown in Table 1 below; and monitor the germina...

Embodiment 2

[0055] Rice bran, pig manure and powdered maturity-promoting mineral granules are used as raw materials for fermentation in a 100L fermenter indoors. First, mix the powdery decomposing-promoting mineral particles with rice bran, then add a certain quality of pig manure, and adjust the carbon-nitrogen ratio to 35. Then add fermentation bacteria liquid (1L / fresh material), and further add appropriate amount of water to adjust the moisture content to about 60%. Take no decomposing-promoting mineral particles as the control group (CK), and add 10% decomposing-promoting mineral particles (accounting for 10% of the fresh weight of the total material) as test 1 (T1). The fermentation period is 50 days, and the changes in the germination index are monitored during the process, such as Figure 7 shown.

[0056] Depend on figure 2 It can be seen that the changing trends of the two are basically consistent, and the germination index continues to increase with the fermentation. In co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com