Commercial vehicle seat rotating mechanism

A technology for rotating mechanisms and commercial vehicles, which is applied in the direction of movable seats, etc. It can solve the problems of small space for installing seats, and the rotating mechanism does not meet the installation requirements, etc., and achieves the effect of small size, meeting strength requirements, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

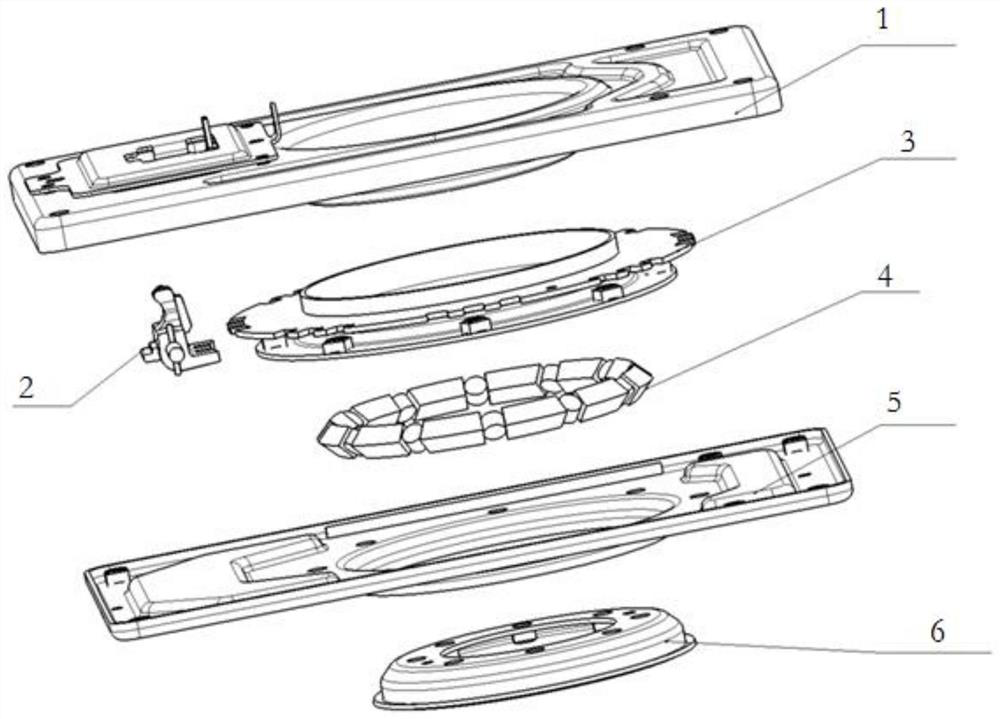

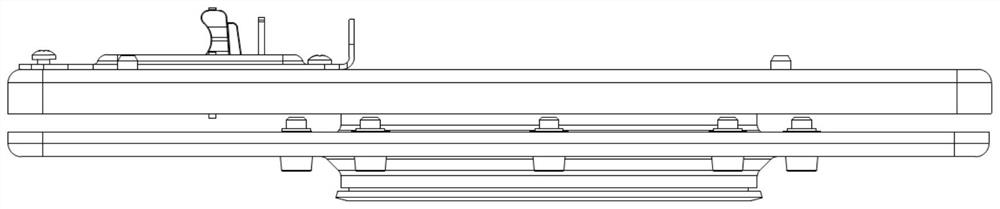

[0038] Such as Figure 1 to Figure 5 As shown, a commercial vehicle seat rotation mechanism includes an upper turntable 1, a pawl 2, a middle turntable 3, cross rollers 4, a fixed seat 5, and a lower turntable 6; the bottom surface of the upper turntable 1 and the top surface of the lower turntable 6 pass through several The bolts are connected to form the inner ring of the rotating mechanism; the upper turntable 1 is provided with a middle hole, and the wall of the middle hole extends downwards to extend out of the neck of the turntable; The middle hole, the middle hole is set on the outer periphery of the lower turntable 6; the bottom of the middle turntable 3 is connected with the fixed seat 5 by several bolts to form the outer ring of the rotating mechanism; the outer ring of the rotating mechanism and the inner ring of the rotating mechanism are connected by cross rollers 4 in rotation ; The ratchet 2 is rotationally connected with the upper turntable 1, and a rotation re...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that: in this embodiment, the rotation reset mechanism is a return spring, the return spring is sleeved on the rotating shaft 21 of the ratchet 2, and the two ends of the return spring are respectively fixed on the ratchet. On the claw mounting plate body 131 and the rotating shaft 21.

[0056] The working principle of this embodiment is:

[0057] In the initial state, the pawl 2 is locked with the ratchet 32 of the middle turntable, and the relative position of the inner ring of the rotating mechanism and the outer ring of the rotating mechanism is locked;

[0058] When the seat needs to be rotated, the ratchet 2 is operated with a cable or a cylinder, so that the ratchet 2 is rotated downwards and disengaged from the ratchet 32 of the middle turntable, so as to realize the unlocking of the inner ring of the rotating mechanism and the outer ring of the rotating mechanism;

[0059] Then turn the upper turnt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com