Floating supporting structure of ball screw pair and method for preventing shaking

A ball screw pair and floating support technology, used in metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve problems such as sag deflection jitter, and achieve the effects of improving smooth performance, reducing support span, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

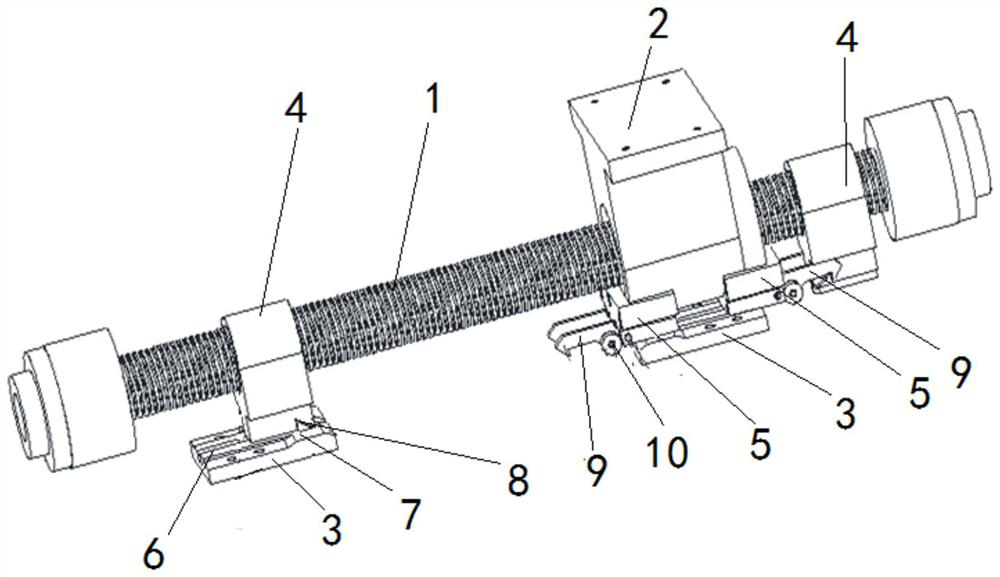

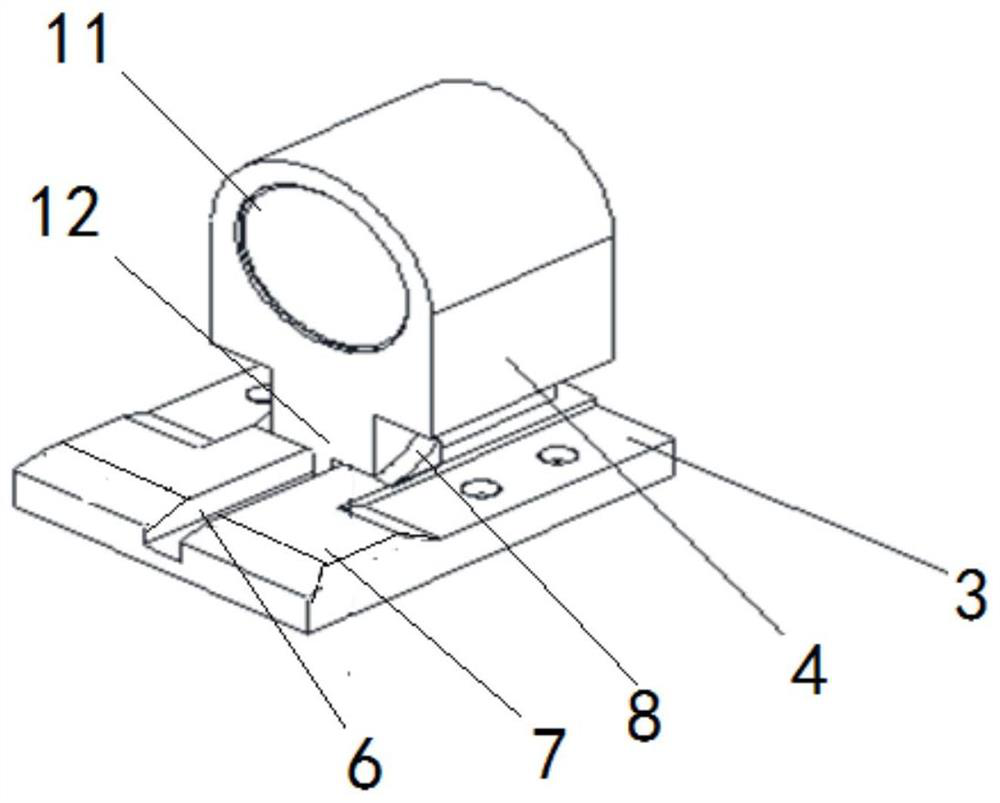

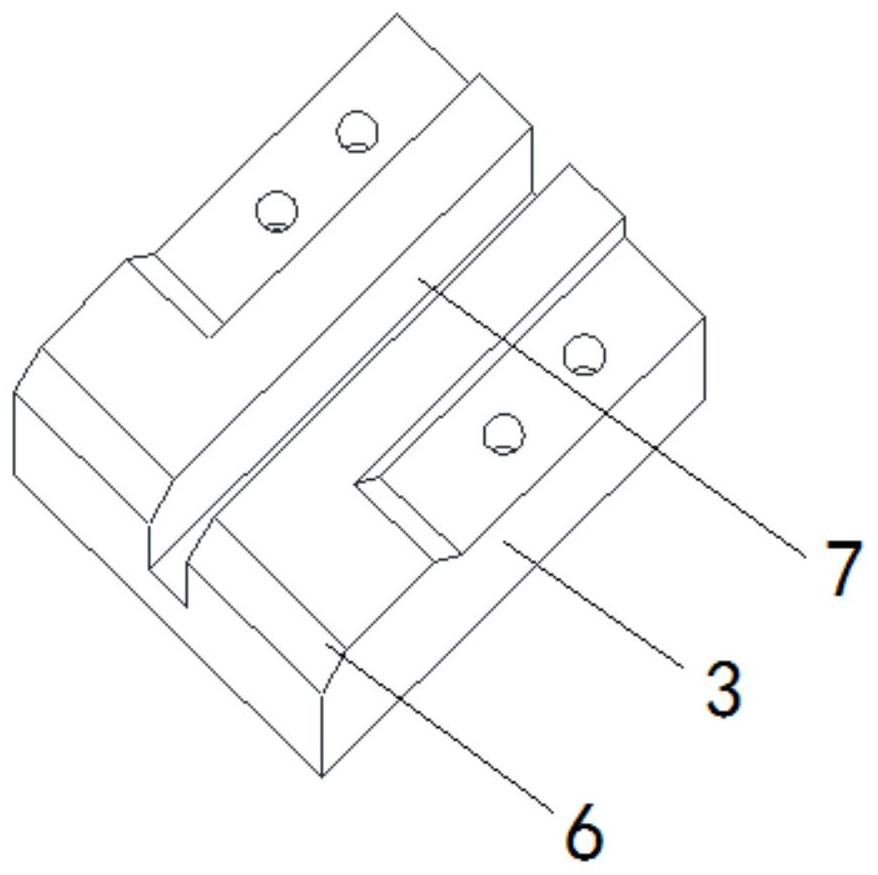

[0020] Referring to the accompanying drawings, the floating support structure of the ball screw pair of the present application includes a matching screw 1 and a screw nut 2, the two ends of the screw 1 are horizontally connected to the machine platform, and the floating support structure includes a fixed-point support plate 3 , the floating support seat 4 and the return return seat 5, the fixed-point support plate 3 is fixed on the machine tool platform below the middle part of the lead screw 1, and the fixed-point support plate 3 is provided with a track 6 parallel to the lead screw 1. In the embodiment , the track is a grooved track with open ends. Both sides of the track 6 are provided with trapezoidal bosses 7. In the embodiment, the top surface of the trapezoidal bosses 7 and the slopes on both sides are smooth and smooth, and its width matches the outer roller 10 of the reset pawl, so that the rollers can move along the trapezoidal bosses 7. Up or down the slope of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com