Two-component paste, application and preparation method of bone cement

A bone cement and paste technology, applied in the field of bone cement, can solve the problems of uneven powder mixing, too fast initiation rate, fast response, etc., and achieve the effects of reducing the risk of fracture, smooth and rapid response, and prolonging the application time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

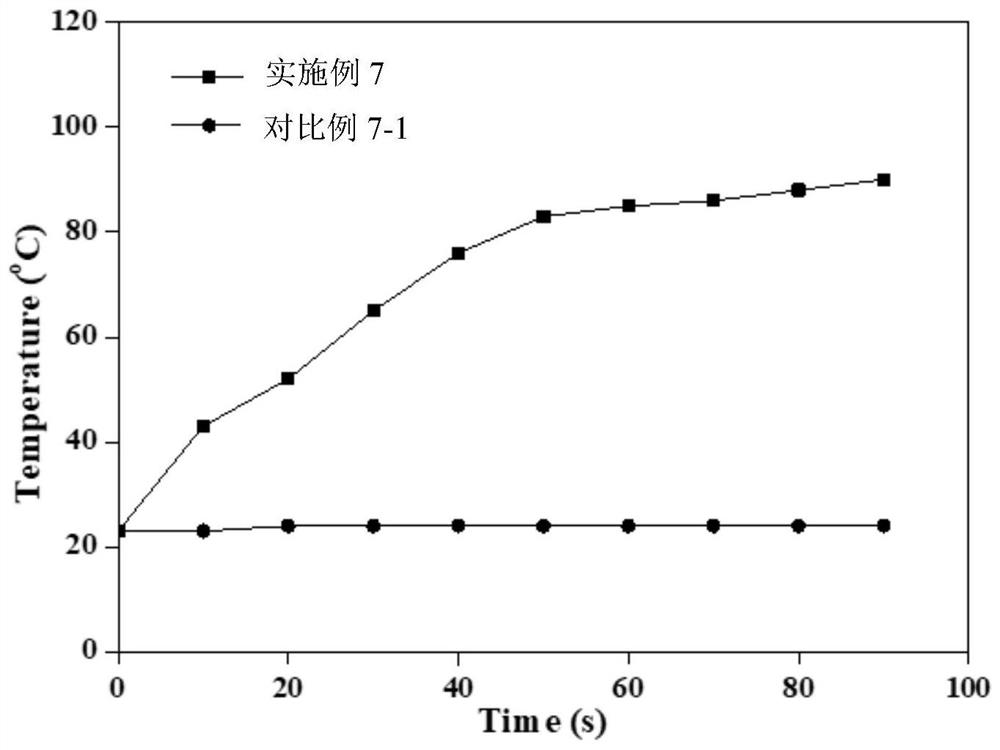

[0081] use Two-component glue gun, the two paste components are loaded into the glue gun separately, the air is evacuated and the two hoses are sealed. The concrete formula of two kinds of pasty components is with reference to the formula among the embodiment 1. There is a static mixing device at the front end of the rubber tube. The extruded two pastes can enter the application period after being fully contacted and mixed in the mixing device. The reaction proceeds within 15 minutes after the injection is completed, and the bone cement solidifies quickly. The prepared bone cement was irradiated with infrared light, and the temperature was measured with an infrared camera. The result is as figure 1 As shown, it means that the photothermal effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com