Method and apparatus for manufacturing electrode stack

A technology for stacking parts and electrodes, which is applied in the manufacturing of electrical components, battery electrodes, and final products, etc., can solve the problems of time-consuming and slow gripper systems in the manufacturing process of electrode stacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

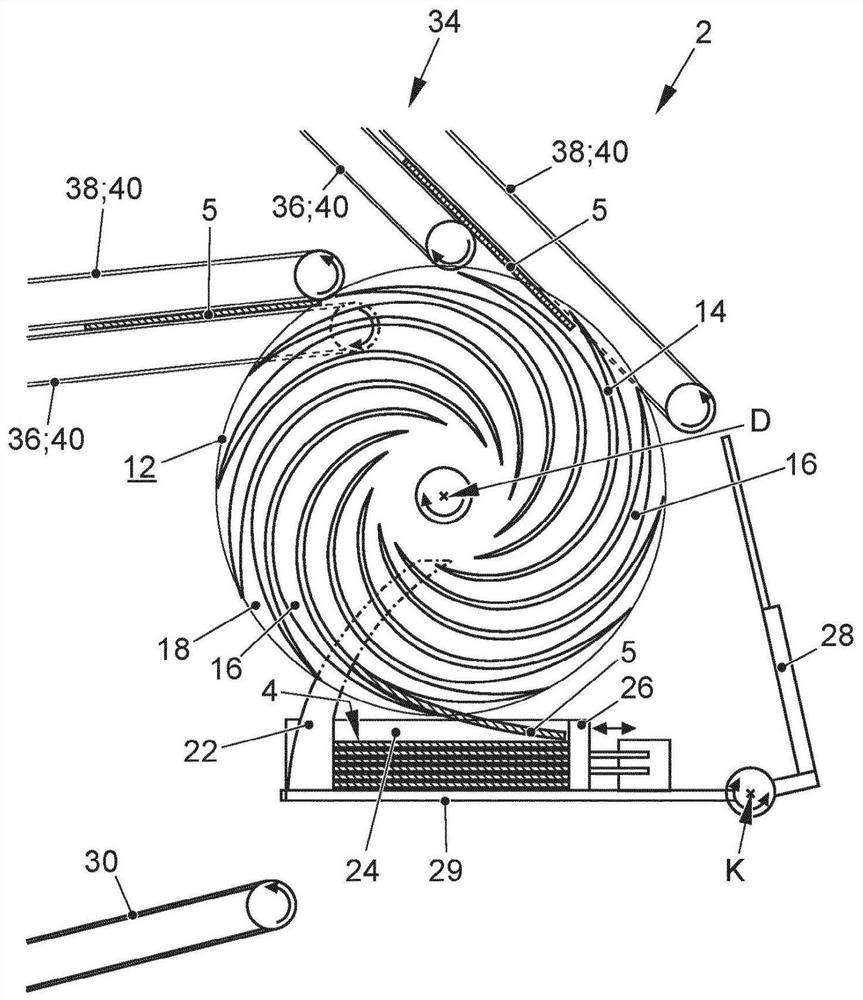

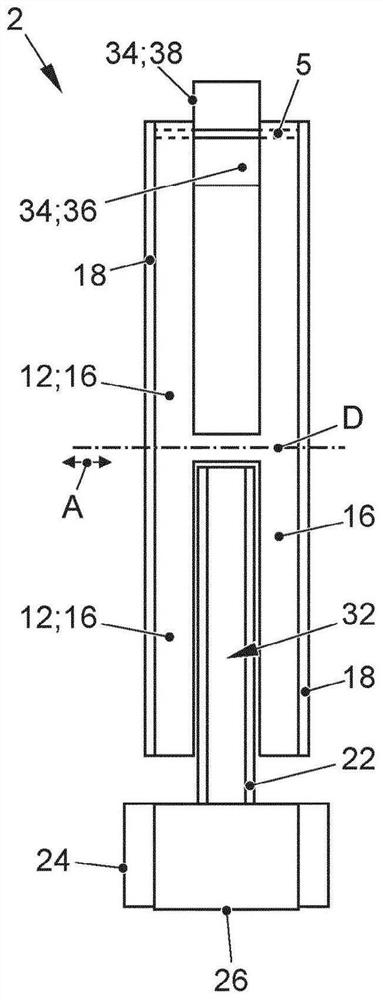

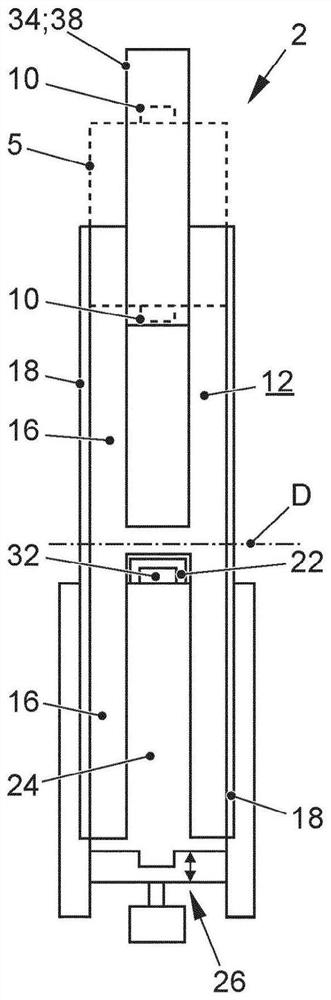

[0043] figure 1 and Figure 2a and FIG. 2 s shows a first variant of a device 2 for producing an electrode stack 4 formed from a single cell 5 . Figure 5 One of the single cells is shown. The cell 5 is here formed from an anode 6 and a cathode 8 , wherein a separator 9 is arranged between the anode 6 and the cathode 8 . Furthermore, a further separator 9 is arranged on the side of the cathode 8 facing away from the anode 6 . Here, anode 6 , cathode 8 and separator 9 are joined to one another by lamination. The anode 6 and the cathode 8 are here in the form of plates. Furthermore, the anode 6 and the cathode 8 each have an electrical contact 10 , which is also referred to as a protrusion. For the purpose of improved clarity, the Figure 1 to Figure 3b A single cell 5 is shown simplified in .

[0044] The electrode stack 4 is provided here for a lithium-ion battery (not shown further), for example a (traction) battery of an electrically driven motor vehicle. The device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com